Continuous casting method for high-aluminum steel plate blank

A steel slab and high-alumina technology, applied in the field of continuous casting of high-alumina steel slabs, can solve problems such as unguaranteed casting slab surface quality, changes in viscosity, melting point, crystallization performance and heat flow physical and chemical properties, and affecting the smooth flow of casting, etc., to achieve Effect of avoiding defects, preventing defects, and stabilizing casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

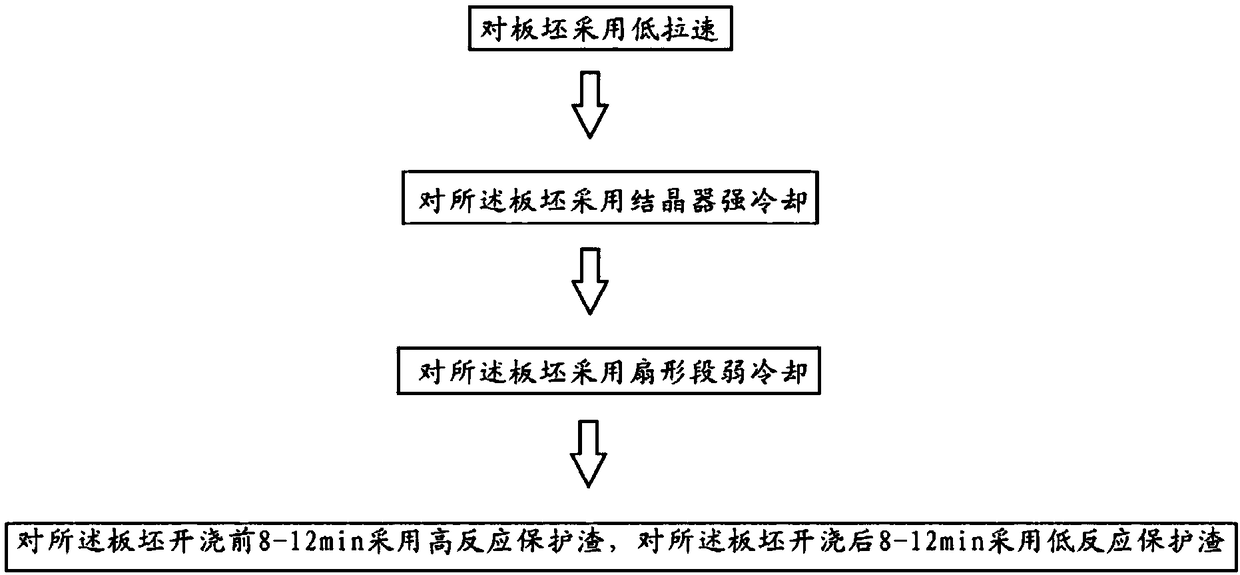

[0013] see figure 1 , a method for continuous casting of high-aluminum steel slabs provided in an embodiment of the present invention, the aluminum content of the high-aluminum steel slabs is 0.3-3.0%, and the method for continuous casting of high-aluminum steel slabs includes the following steps:

[0014] In step 1, a low casting speed is used for the slab.

[0015] In step 2, the slab is intensively cooled with a crystallizer.

[0016] In step 3, weak fan cooling is used for the slab.

[0017] Step 4: Use high-reaction mold flux for 8-12 minutes before the slab is poured, and use low-reaction mold flux for 8-12 minutes after the slab is poured.

[0018] Because the present application adopts low drawing speed to the slab, it can prevent defects on the surface of the slab. Because the slab is cooled by the crystallizer, it accelerates the solidification of the slab in the crystallizer and prevents defects on the surface of the slab. The slab is weakly cooled in a fan-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com