Rope-rod hybrid driving super-redundant robot

A hybrid drive and robot technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of increasing the inertia of moving parts, small working space, and reduced operating speed, and achieve the elimination of sliding friction, large working space, high The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

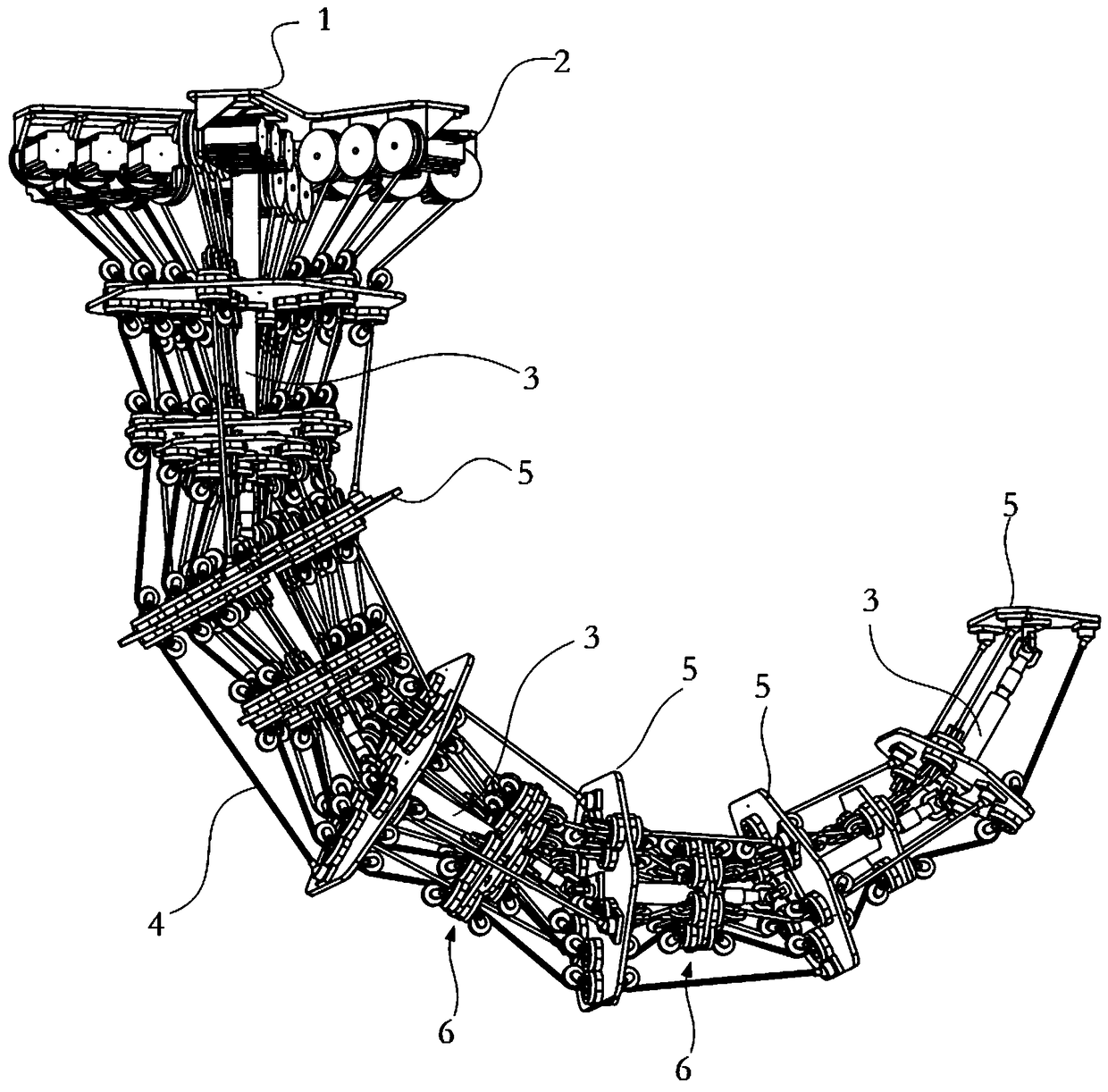

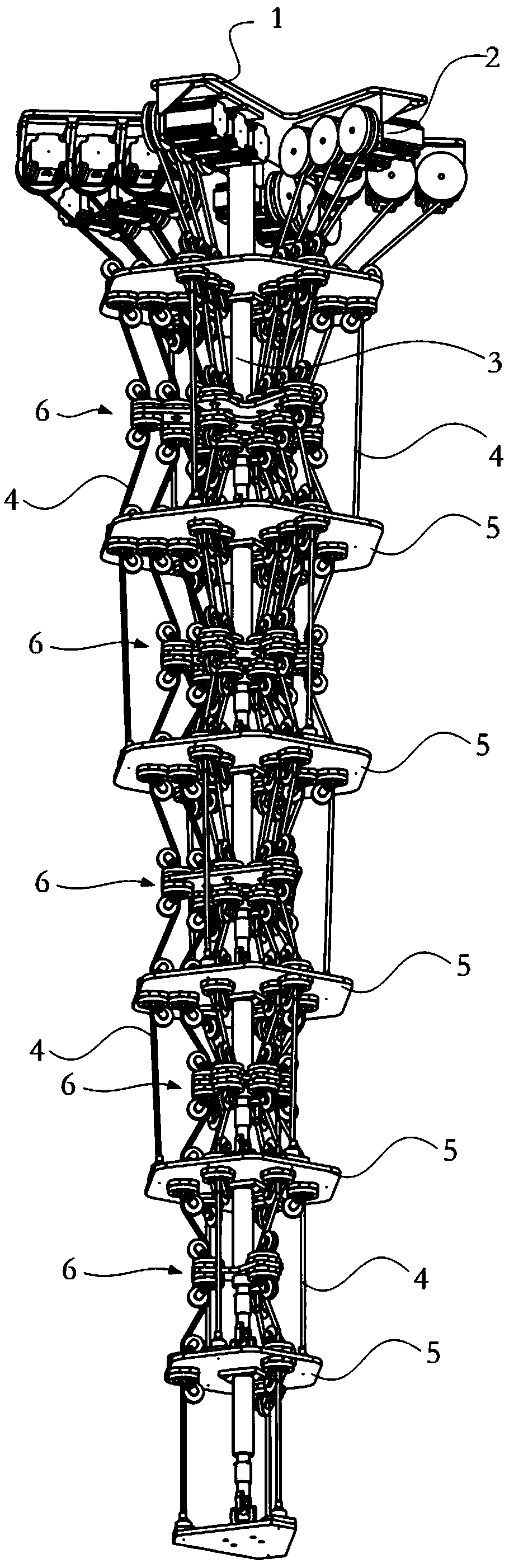

[0021] refer to figure 1 , figure 2 The schematic diagram of the structure is shown.

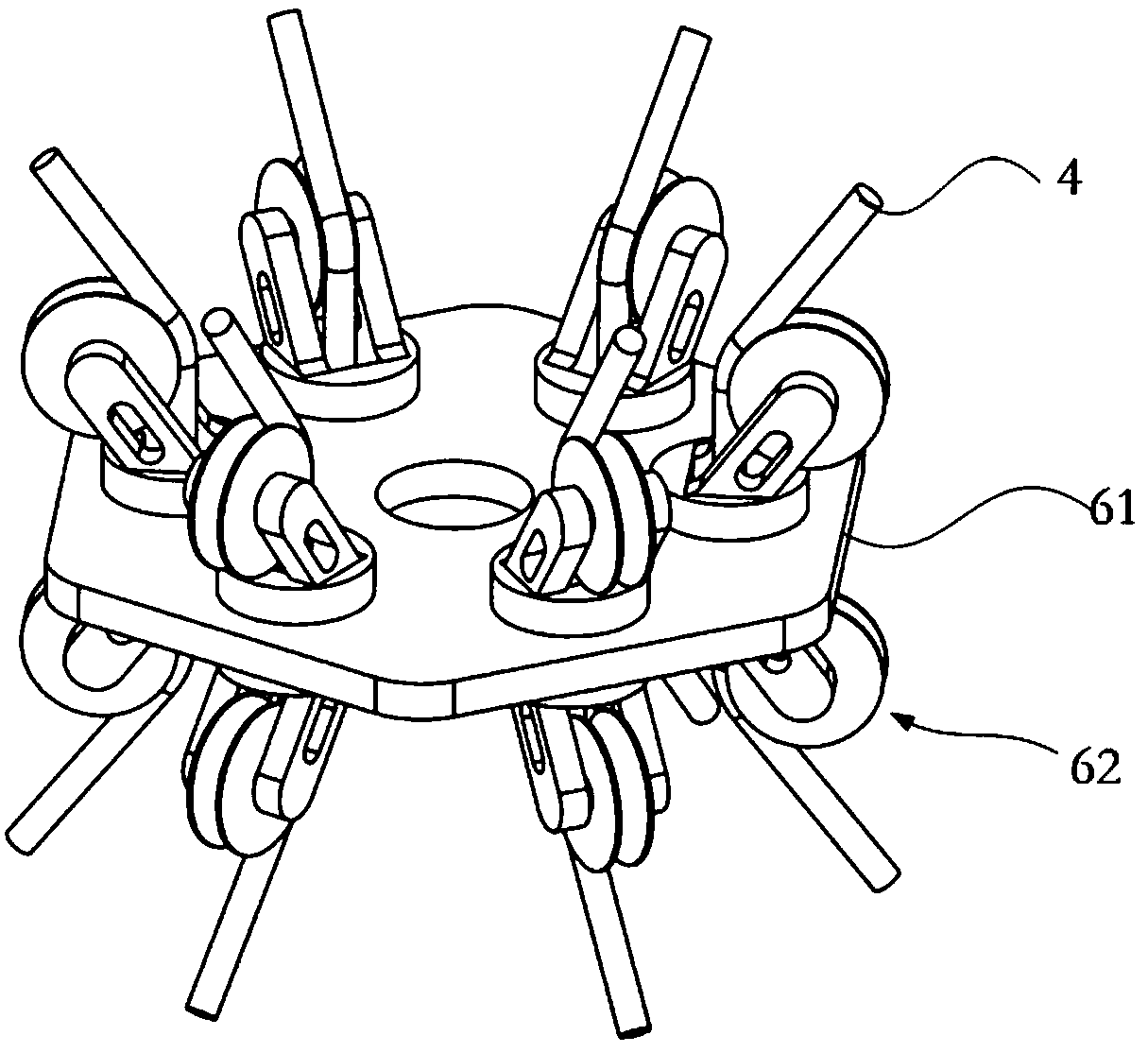

[0022] A rope-rod hybrid drive super-redundant robot in an embodiment of the present invention includes a base 1, a number of motors 2 mounted on the base, a number of rod chains 3, a number of rope chains 4, and a number of moving platforms 5 , Rope holding device 6.

[0023] Several moving platforms 5 are respectively connected by several rod-system branch chains 3 to form a series-integrated structure, and the head end is fixedly arranged on the base 1, and several rod-system branch chains 3 form a spine of the present invention.

[0024] A rope branch chain 4 is connected between some moving platforms 5 and the take-up reels 21 of the motor 2 on the base 1 , so that each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com