Tensioning device and production method for producing laminated beam or laminated plate using same

A technology of tensioning device and laminated plate, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve problems such as low production efficiency, crack resistance, bending stiffness, compressive strength, and poor seismic performance, and achieve Guaranteed strength, excellent compressive strength and seismic performance, and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

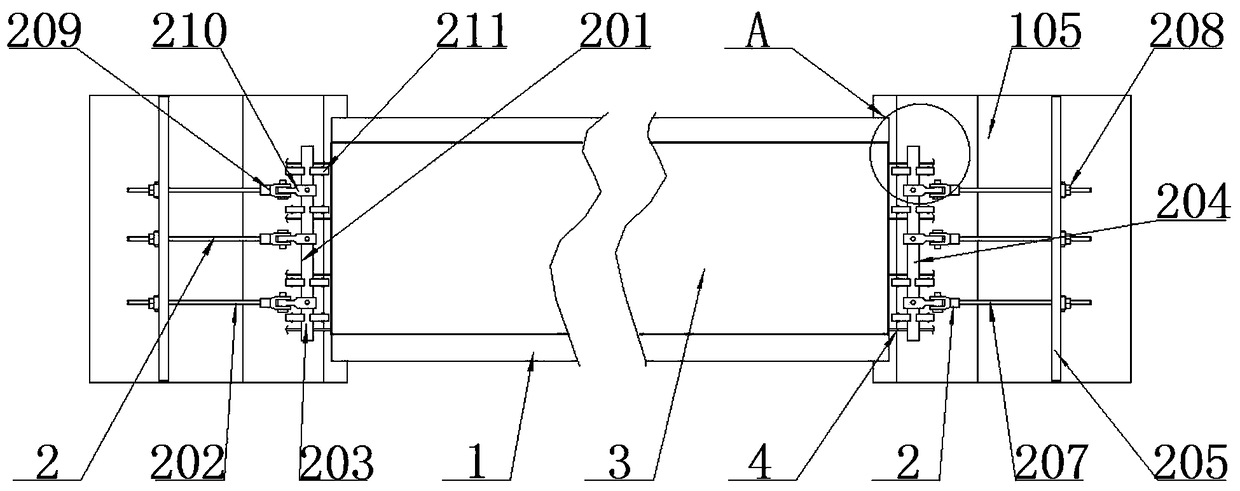

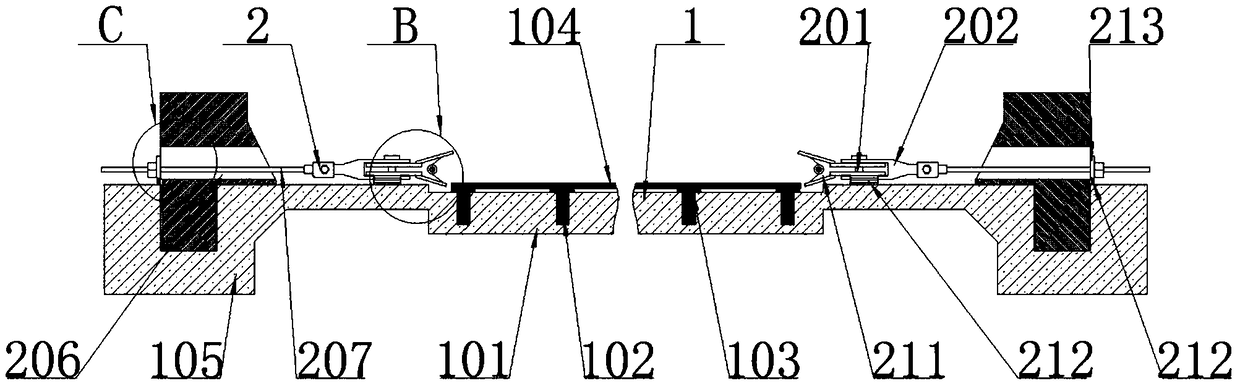

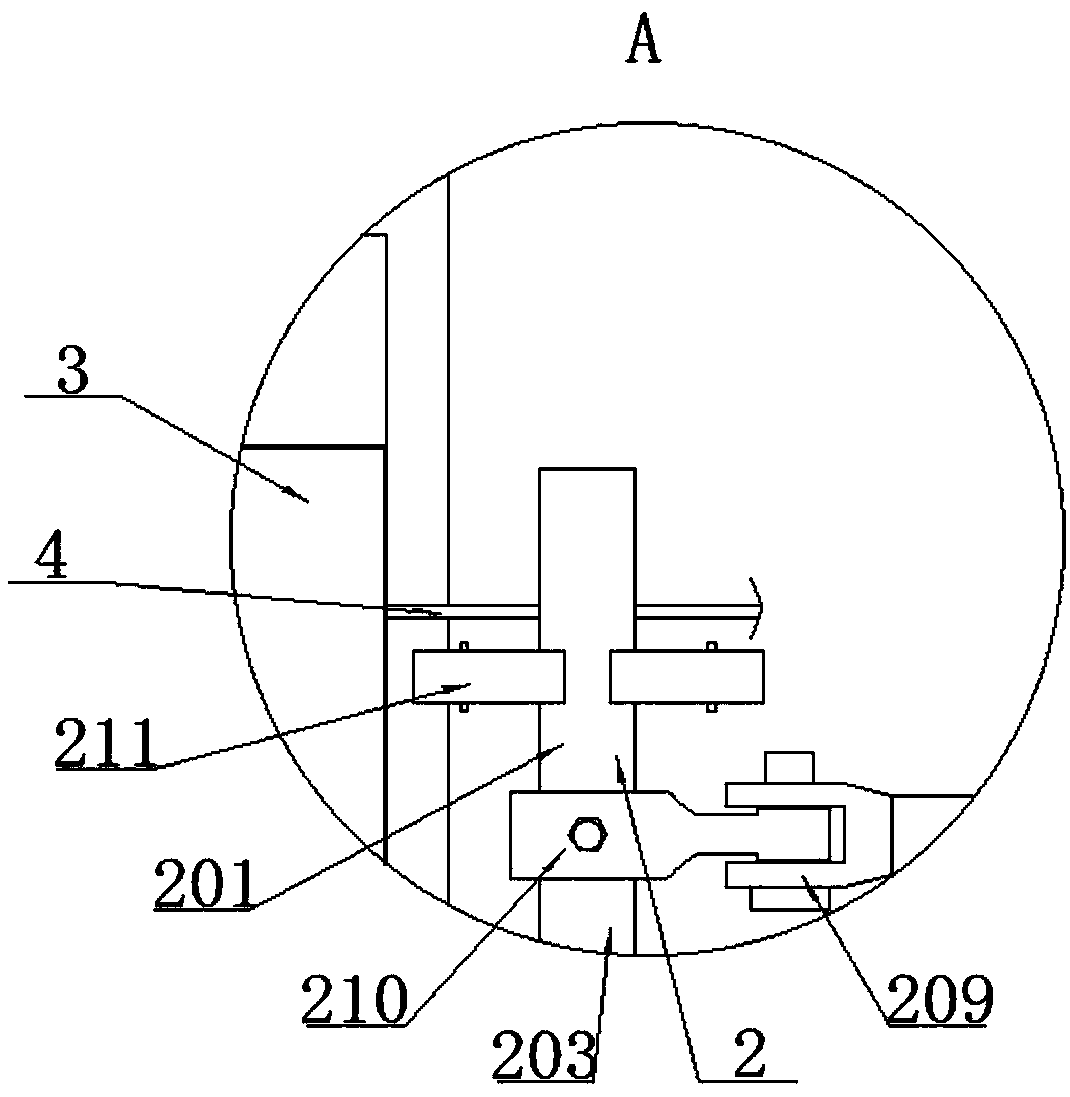

[0031] Such as Figure 1-5 Said is a tensioning device for producing laminated beams or laminated slabs, including a working platform 1 for solidifying the laminated beams or laminated slabs 3, and the working platform 1 includes a plurality of concretes poured on the ground at intervals. The longitudinal beam 101, the longitudinal direction of the concrete longitudinal beam 101 faces the tension mechanism 2 on both sides, the vertical embedded steel plate 102 is fixed in each concrete longitudinal beam 101, and the upper end of each embedded steel plate 102 extends outside the concrete longitudinal beam 101 , And located on the same horizontal plane, cross beams 103 are connected to the embedded steel plates 102 in the same horizontal direction. The upper surface of each cross steel beam 103 is flush with the upper end of each embedded steel plate 102, and each cross steel beam 103 is connected to each pre-embedded steel plate 102. The buried steel plate 102 is fixedly connect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap