Ink-jet printing machine sprayer cleaning device and control method thereof

A technology of cleaning device and control method, applied in printing and other directions, can solve the problems of incomplete cleaning and low cleaning efficiency, and achieve the effects of thorough cleaning, strong versatility and less waste liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

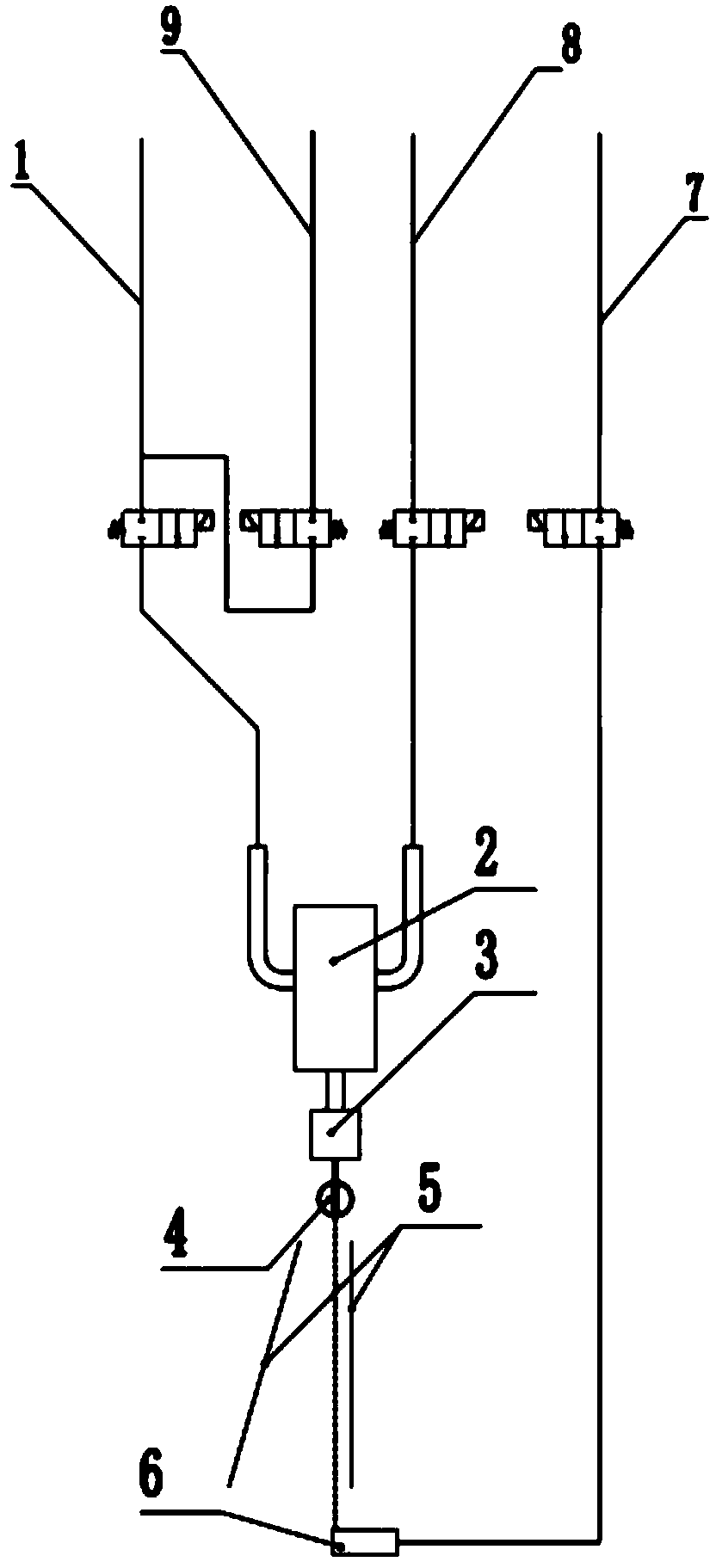

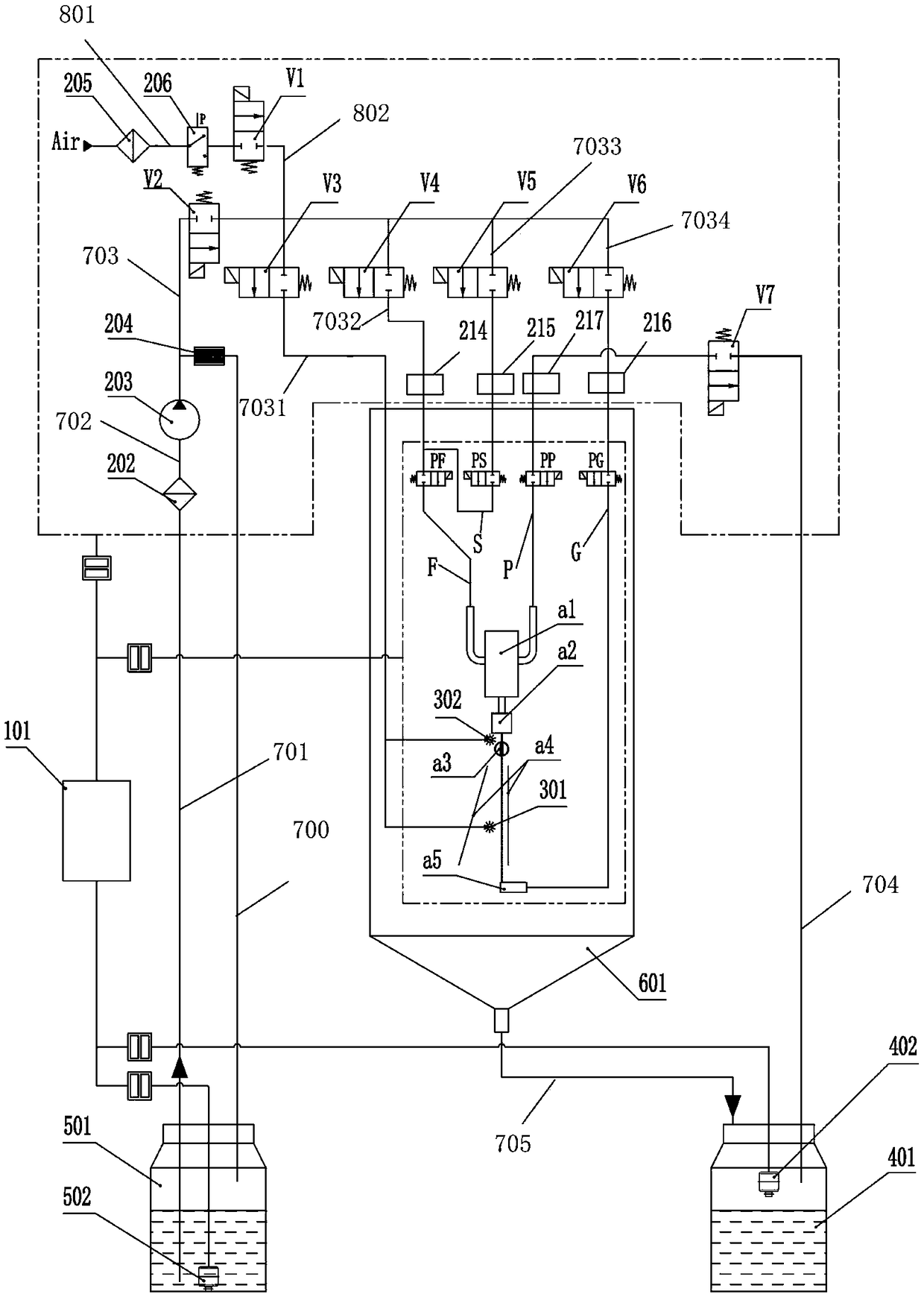

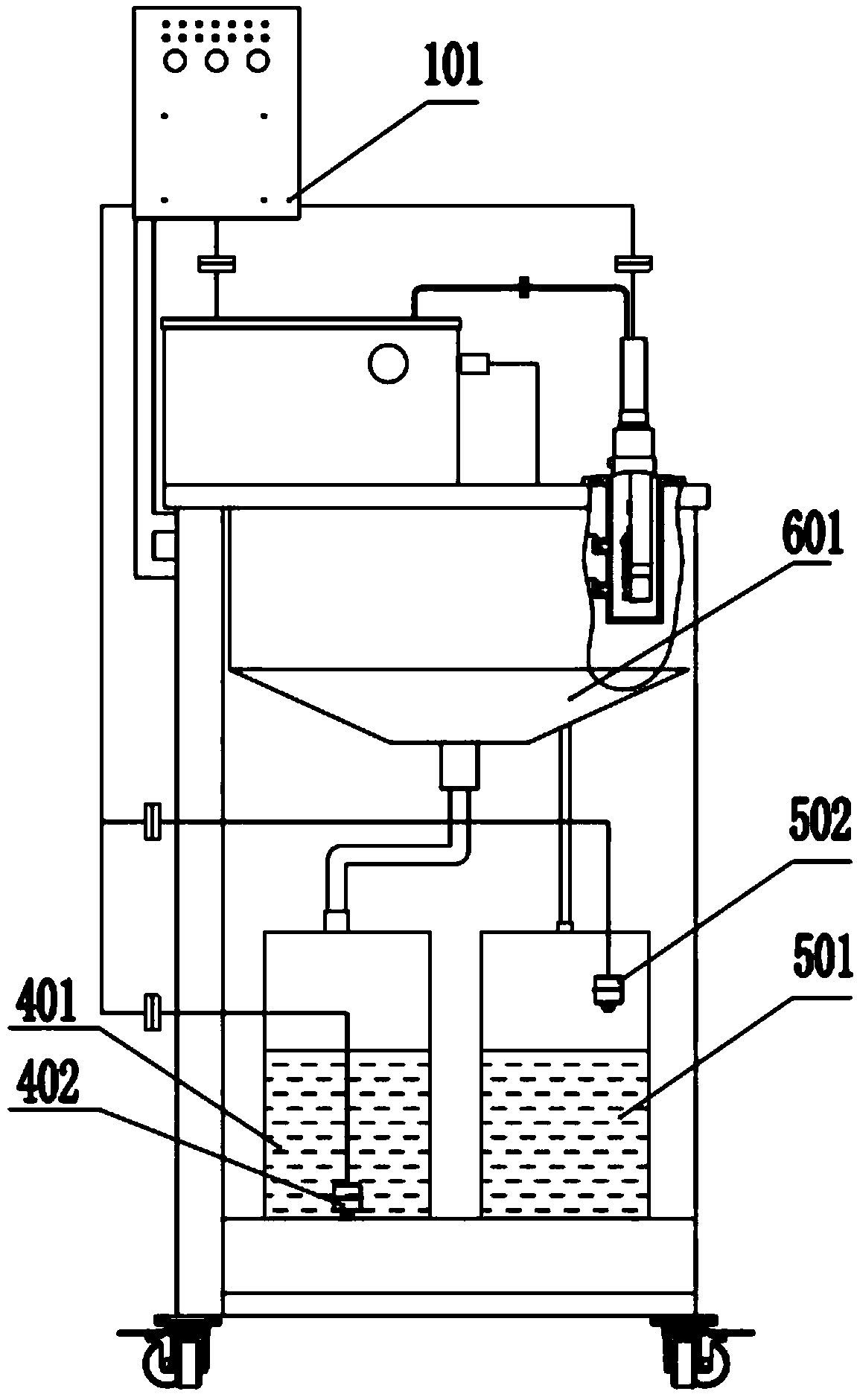

[0053] refer to Figure 2-Figure 4 , this embodiment provides a cleaning device for the inkjet printer nozzle, which is applied to the inkjet printer nozzle, and the inkjet printer nozzle includes a supply pipe F, an overflow pipe P, a recovery pipe G, a solvent pipe S, a spray chamber a1, Nozzle a2, charging electrode a3, deflection electrode pair a4, recovery tank a5 and circuit connection interface (not shown in the figure);

[0054] The supply pipe F is connected to one end of the spray chamber a1, the other end of the spray chamber a1 is connected to the overflow pipe P, the spray chamber a1 is fixedly connected to the nozzle a2, and the charging electrode a3, the deflection electrode pair a4 and the recovery tank a5 are arranged in cooperation with the nozzle a2 , the solvent pipe S is connected to the supply pipe F, the recovery pipe G is connected to the recovery tank a5, the supply valve PF is set on the supply pipe F, the overflow valve PP is set on the overflow pipe...

Embodiment 2

[0091] refer to Figure 2-Figure 4 , this embodiment provides a method for controlling the cleaning device of the inkjet printer nozzle, which is applied to the cleaning device of the inkjet printer nozzle described in Embodiment 1, and the method includes:

[0092] The control device 101 receives the start-up command, and controls the first liquid level gauge 502, the second liquid level gauge 402 and the air pressure switch 206 to collect the first liquid level information of the cleaning liquid tank 501 and the waste liquid recovery tank 401 according to the start-up command. The second liquid level information and the air pressure information on the first air circuit 801;

[0093] Judging whether the liquid level in the cleaning liquid tank 501 is higher than the first preset liquid level according to the first liquid level information, and judging whether the liquid level in the waste liquid recovery tank 401 is lower than the second preset liquid level according to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com