High temperature superconducting material, and preparation method thereof

A superconducting material, high temperature technology, applied in the field of superconductivity, can solve the problems of insufficient upper critical magnetic field, low superconducting critical current, low superconducting critical temperature, etc., achieve high superconducting critical current, simple preparation method, The effect of a large critical magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A method for preparing a high-temperature superconducting material, comprising the following steps:

[0046] Step 1, Ba(NO 3 ) 2 , Ca(NO 3 ) 2 、TiO 2 , Cu(CN) was added into the quartz mortar according to the stoichiometric ratio and stirred for 40-60 minutes; the raw materials of each of the above components were fully mixed evenly to obtain a mixture slurry;

[0047] Step 2: Put the above-mentioned mixture slurry into a quartz boat, put it into a tube furnace, pass through oxygen, and heat and bake at 800-900°C for 20-24 hours in an oxygen atmosphere; then take it out, grind it into particles, and then re- Put it into a quartz boat, heat and bake at 800-900°C for 20-24 hours to obtain the precursor block;

[0048] Step 3: After taking out the precursor block, add Ti 2 o 3 Mix and grind for 50-60 minutes, grind into powder, the particle size of the powder is between 10nm-10μm; then use a tablet press, set the pressure value to 4-5t / cm 2 , press the abrasive par...

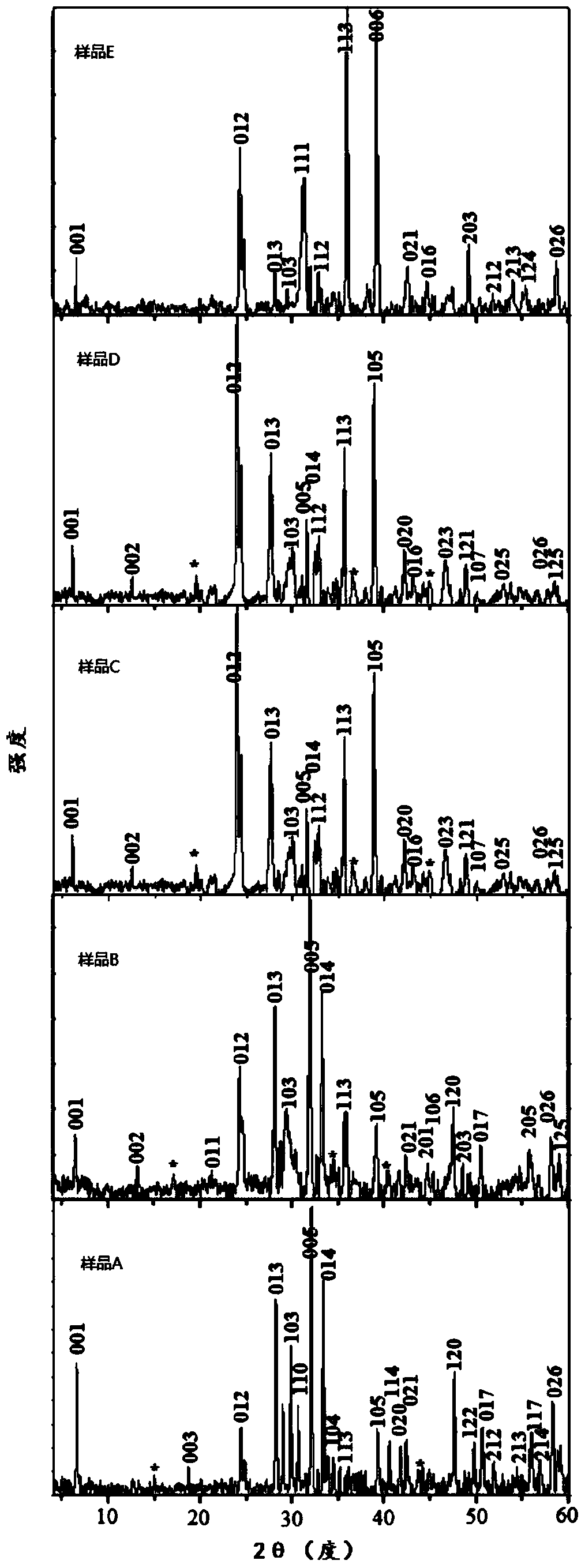

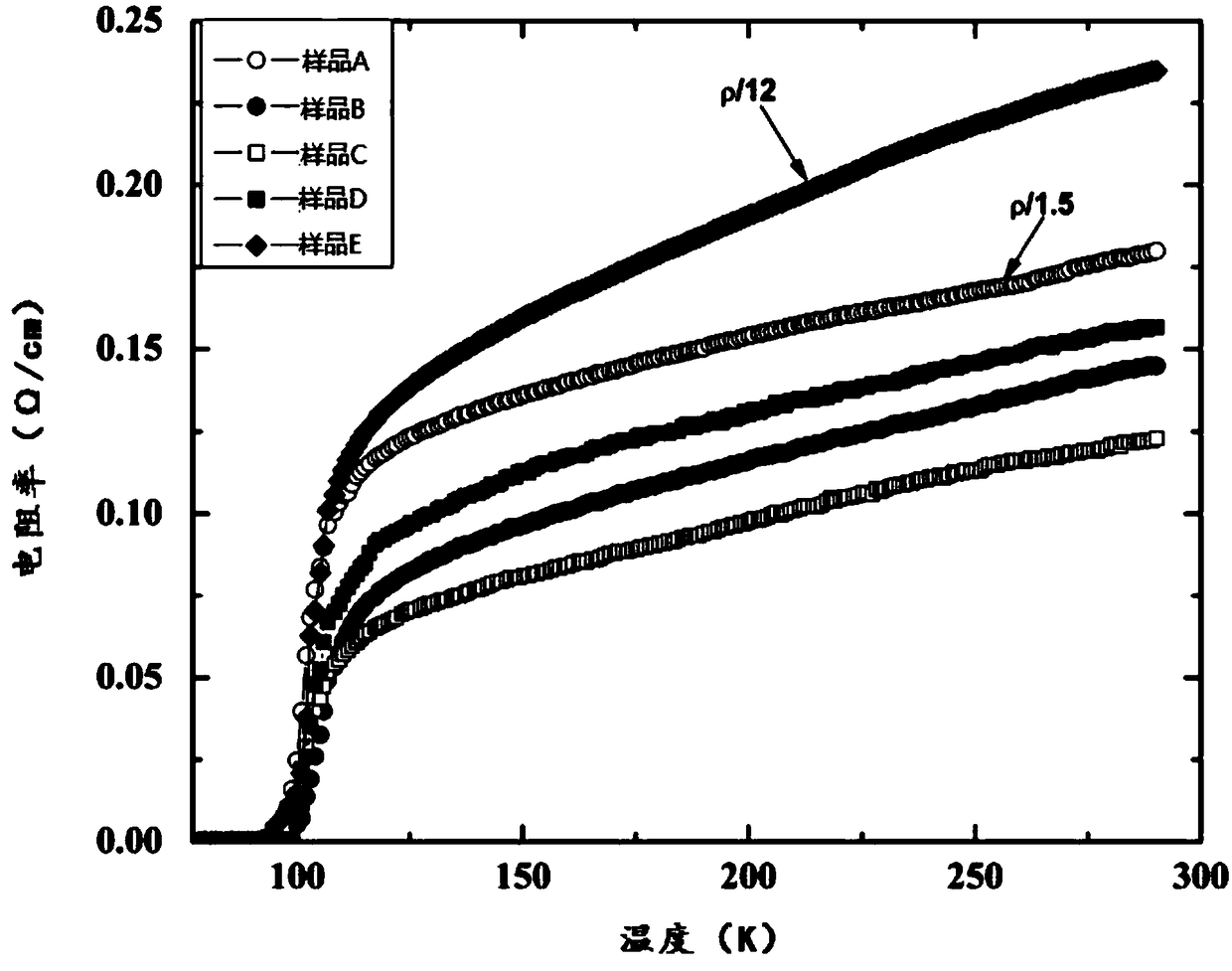

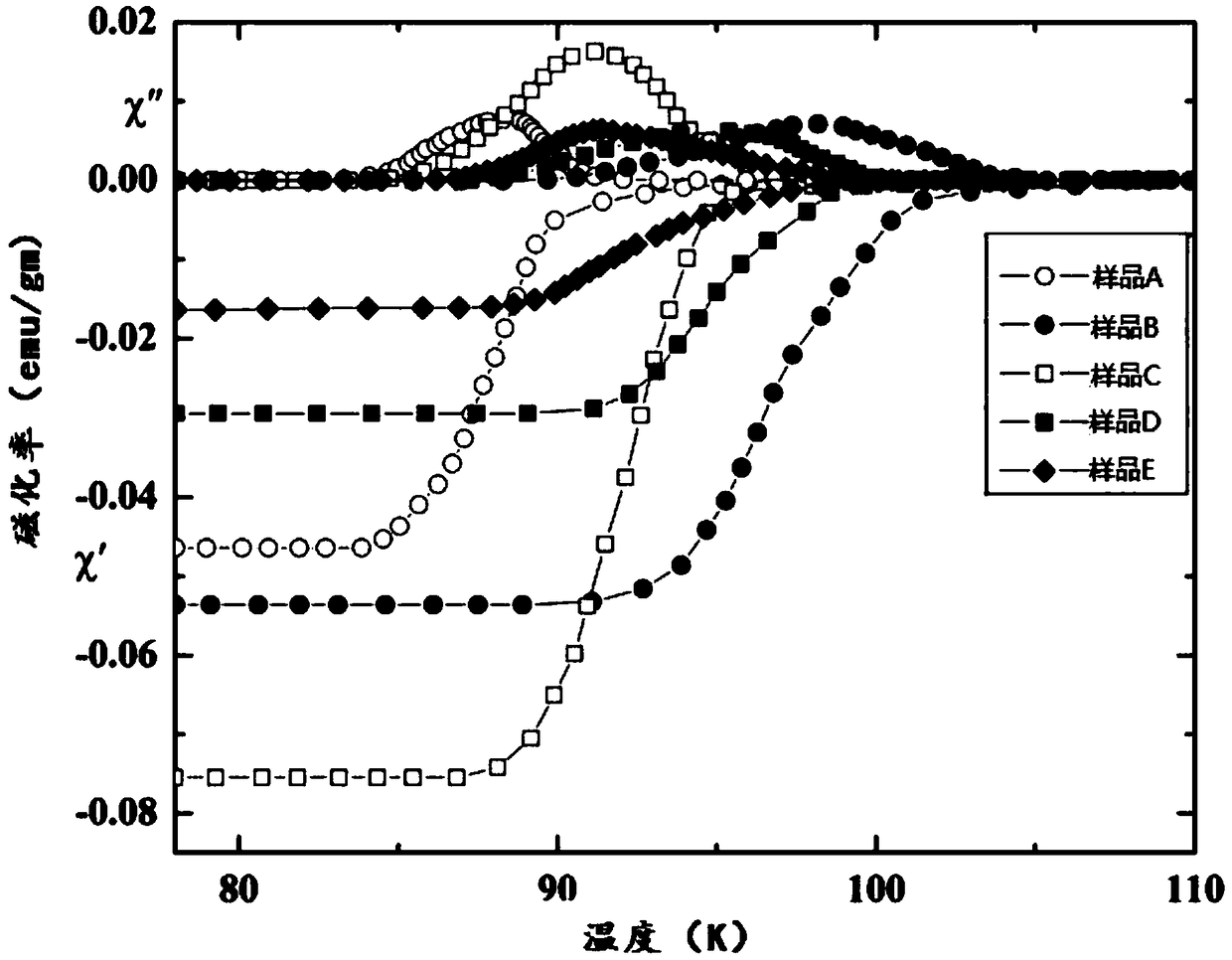

Embodiment 1

[0055] A high-temperature superconducting material, the general chemical formula of which is:

[0056] Ti z -(Cu 0.5 Ti 0.5 ) Ba 2 (Ca 2-x Ti x ) CuO 10-y , where x=0, y=1.0, z=2;

[0057] A method for preparing a high-temperature superconducting material, comprising the following steps:

[0058] Step 1, Ba(NO 3 ) 2 , Ca(NO 3 ) 2 、TiO 2 , Cu(CN) was added into the quartz mortar according to the stoichiometric ratio and stirred for 40-60 minutes; the raw materials of each of the above components were fully mixed evenly to obtain a mixture slurry;

[0059] Step 2. Put the above mixture slurry into a quartz boat, put it into a tube furnace, pass through oxygen, and bake at 800°C for 20 hours in an oxygen atmosphere; then take it out, grind it into particles and put it into the quartz boat again After heating and baking at 800°C for 20 hours, the precursor block was obtained;

[0060] Step 3: After taking out the precursor block, add Ti 2 o 3 Mix and grind for 50-6...

Embodiment 2

[0066] A high-temperature superconducting material, the general chemical formula of which is:

[0067] Ti z -(Cu 0.5 Ti 0.5 ) Ba 2 (Ca 2-x Ti x ) CuO 10-y , where x=0.25, y=1.0, z=2;

[0068] A method for preparing a high-temperature superconducting material, comprising the following steps:

[0069] Step 1, Ba(NO 3 ) 2 , Ca(NO 3 ) 2 、TiO 2 , Cu(CN) was added into the quartz mortar according to the stoichiometric ratio and stirred for 40-60 minutes; the raw materials of each of the above components were fully mixed evenly to obtain a mixture slurry;

[0070] Step 2. Put the above mixture slurry into a quartz boat, put it into a tube furnace, pass through oxygen, and bake at 800°C for 20 hours in an oxygen atmosphere; then take it out, grind it into particles and put it into the quartz boat again After heating and baking at 800°C for 20 hours, the precursor block was obtained;

[0071] Step 3: After taking out the precursor block, add Ti 2 o 3 Mix and grind for 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com