Viscosity reduction treatment tank for oil pumping of oil well

A technology for treating tanks and pumping oil, which is applied in the petroleum industry, refined hydrocarbon oil, wellbore/well parts, etc. It can solve problems such as increased resistance of crude oil transportation, hidden dangers of pipeline transportation safety, and pipe condensation accidents, etc., to reduce viscosity The effect of improving the transmission efficiency and preventing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

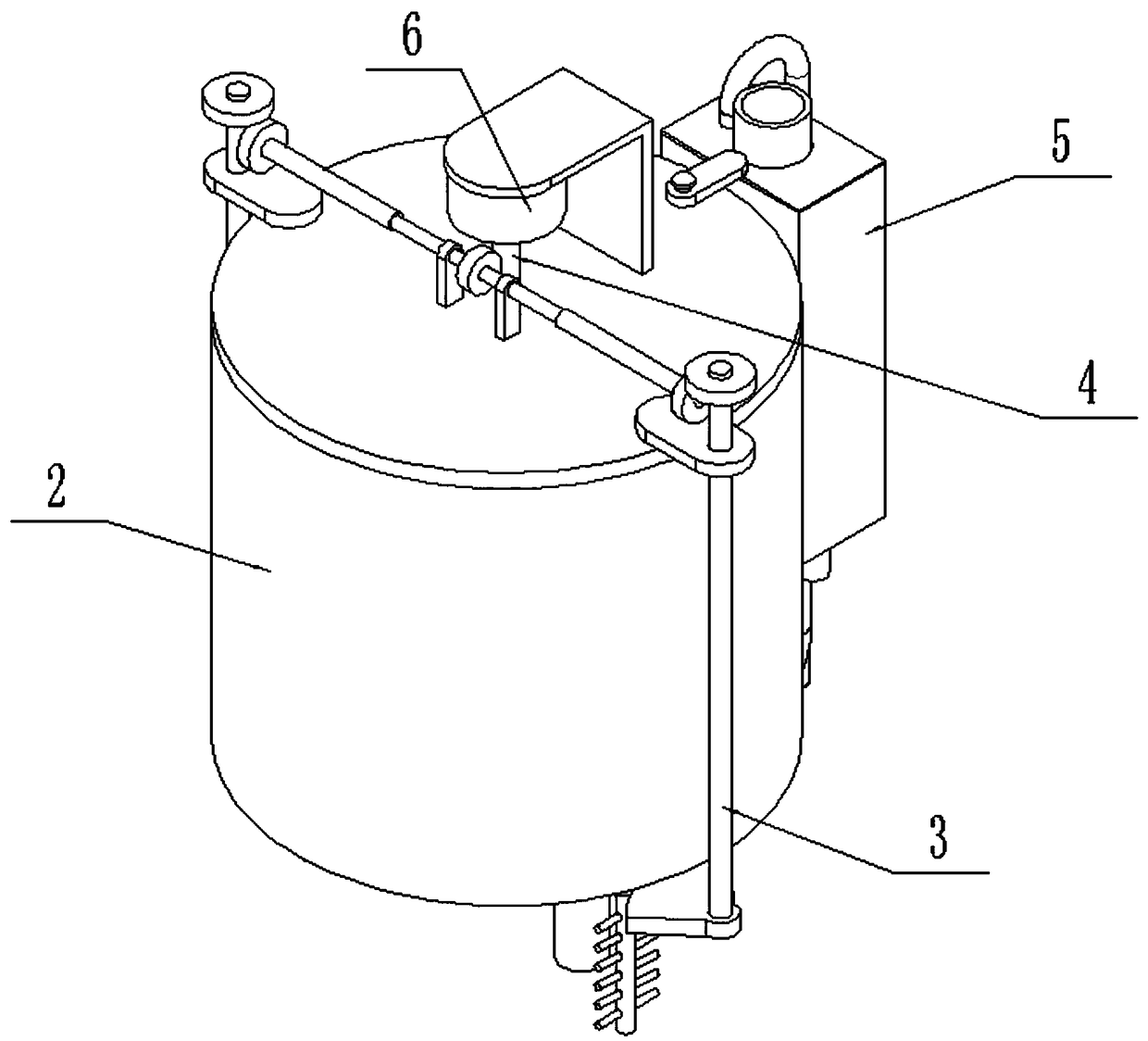

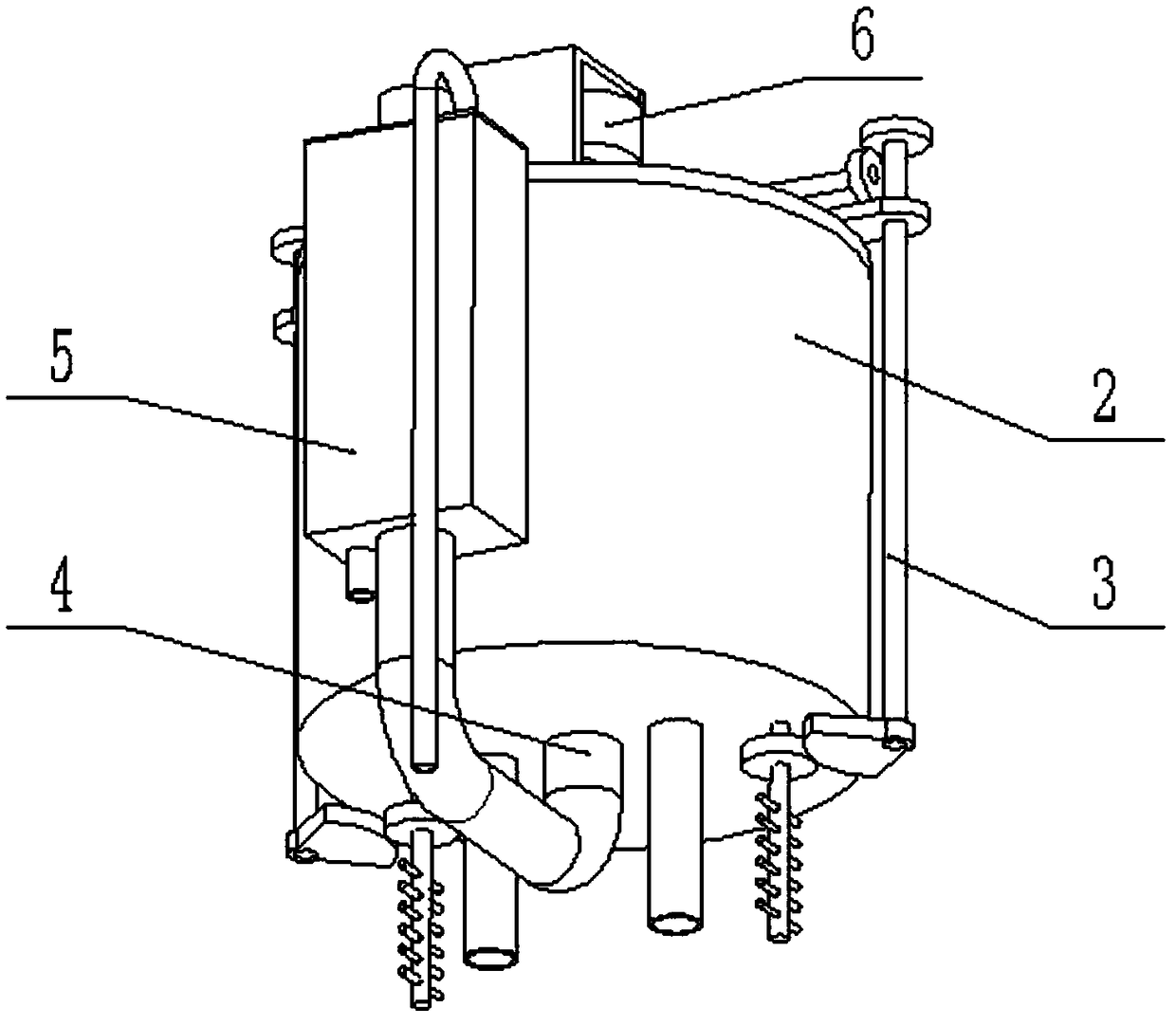

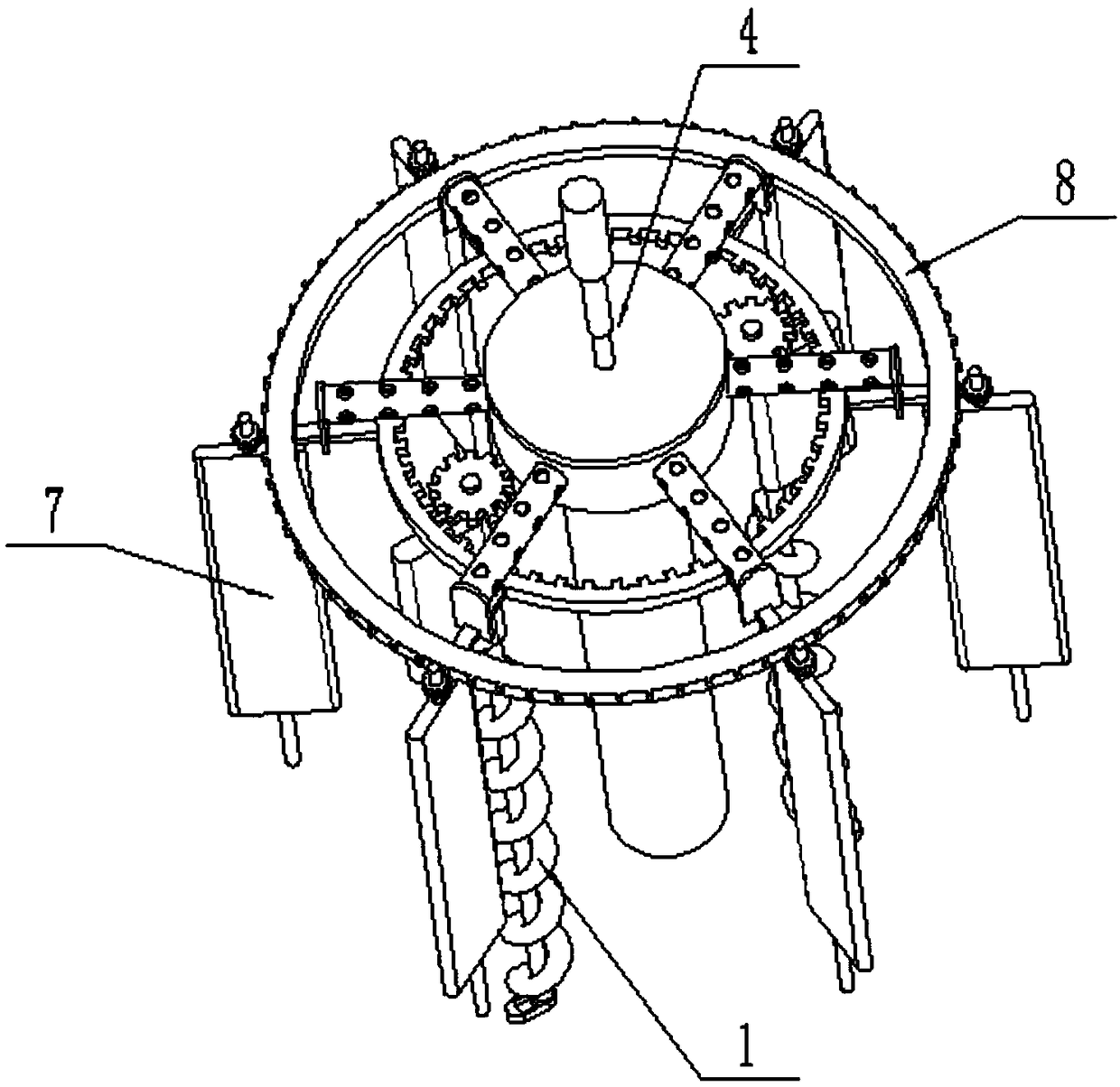

[0029] like Figure 1-11As shown, the viscosity reduction treatment tank for oil well pumping includes oil pump 1, treatment tank 2, stirring viscosity reduction mechanism 3, oil filter pipe 4, heat exchange viscosity reduction pipe 5, driving motor 6, rotary agitator 7 and transmission wheel 8; the treatment tank 2 includes a tank body 2-1, a tank cover 2-2 and an oil suction pipe 2-3; the top end of the tank body 2-1 is sealed and connected to the tank cover 2-2; the tank body 2-1 Both sides of the bottom end are respectively fixedly connected and communicated with an oil suction pipe 2-3; the oil extractor 1 is provided with two, and the upper ends of the two oil extractors 1 are all rotatably connected to the inner side of the tank body 2-1. The lower end of each oil extractor 1 is respectively connected to the inside of two oil extraction pipes 2-3; the upper end of the oil extractor 1 is meshed with the inner end of the transmission wheel 8, and the outer end of the tran...

specific Embodiment approach 2

[0030] like Figure 1-11 As shown, the oil pump 1 includes a sucker rod 1-1, a sucker screw 1-2, a rod seat 1-3, a swirl plate 1-4 and a driven gear 1-5; the sucker rod 1- 1. The driven gear 1-5, the swirl plate 1-4 and the oil suction screw 1-2 are fixedly connected in sequence from top to bottom; the driven gear 1-5 is meshed with the transmission wheel 8; the swirl plate 1-4 The rotation fit is connected to the inside of the tank body 2-1; the oil sucking screw 1-2 is connected to the inside of the oil suction pipe 2-3 and the tank body 2-1 with rotation fit; the lower end of the sucker rod 1-1 is passed through a belt The seat bearing is rotatably connected on the rod seat 1-3, and the rod seat 1-3 is fixedly connected on the inner wall of the oil extraction pipe 2-3.

[0031] When the oil pump 1 is in use, the driven gear 1-5 rotates under the drive of the transmission wheel 8, and when the driven gear 1-5 rotates, it can drive the sucker rod 1-1 to rotate, and the sucke...

specific Embodiment approach 3

[0032] like Figure 1-11 As shown, the oil filter pipe 4 includes a worm screw 4-1, a linkage shaft 4-2, a filter box 4-3, a straight oil delivery pipe 4-4, a plurality of rotating pipes 4-5 with filter holes on the surface, a vertical connection Plate 4-6 and oil delivery screw 4-7; the upper end of the worm 4-1 is connected to the output shaft of the drive motor 6 through a coupling; the lower end of the worm 4-1 is fixedly connected to the linkage shaft 4-2, and the linkage shaft 4-2 is sealed and rotated in the middle of the tank cover 2-2; the middle end of the linkage shaft 4-2 is fixedly connected in the middle of the filter box 4-3, and the lower end of the linkage shaft 4-2 is inserted into the straight oil pipe 4 -4; the lower end of the linkage shaft 4-2 is fixedly connected to the oil delivery screw 4-7, and the oil delivery screw 4-7 is rotated and connected to the inner side of the oil delivery straight pipe 4-4; the worm 4-1 drives Connect the stirring viscosit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com