High-toughness ferrite type hot continuous rolling steel band for oil-gas pipeline and production method of high-toughness ferrite type hot continuous rolling steel band

A production method, ferrite technology, applied in the field of hot continuous rolling steel plate production, can solve the problems of large amount of alloy addition, production method not suitable for ordinary ferritic pipeline steel, strict requirements on equipment and production conditions, etc., and achieve excellent low temperature The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

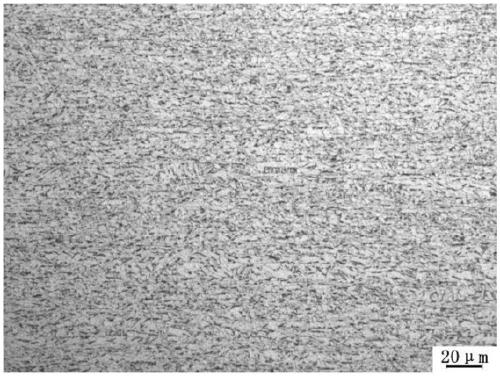

Embodiment 1

[0049] Hot metal pretreatment, converter smelting, LF heating furnace refining, RH vacuum refining, continuous casting to obtain a 220mm thick billet, the specific chemical composition weight percentage is: 0.05C, 0.17Si, 1.32Mn, 0.036Nb, 0.01P, 0.002S, 0.036 Nb, 0.2Cr, 0.09Mo, 0.12Ni, 0.016Ti, 0.033Als, and the rest are Fe and unavoidable impurities; the reheating temperature of the billet is 1192°C, and the furnace time is 245min. Secondary reduction rate is 15%, 19%, 20%, 22%, 22%, 27%, rolling to 54mm; finishing rolling is 7-stand hot continuous rolling, finishing rolling start temperature is 970°C, finish rolling temperature is 780°C, the thickness of the billet after finish rolling is 8.8mm; cooling to 450°C at a cooling rate of 30°C / s, air cooling for 2s, and then cooling to 397°C at a cooling rate of 13°C / s for coiling.

[0050] After testing, the mechanical properties of the pipeline steel produced in this embodiment are: Rt0.5: 537MPa, Rm: 615MPa, A50: 30.0%, Rt0.5 / R...

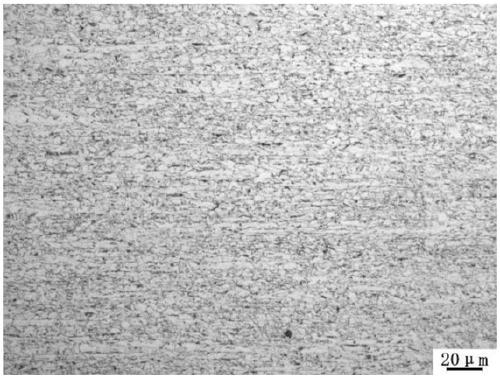

Embodiment 2

[0052]Hot metal pretreatment, converter smelting, LF heating furnace refining, RH vacuum refining, continuous casting to obtain a 230mm thick billet, the weight percentage of the specific chemical composition is: 0.05C, 0.15Si, 1.31Mn, 0.011P, 0.003S, 0.034Nb, 0.19, Cr, 0.11Mo, 0.13Ni, 0.018Ti, 0.031Als; the billet reheating temperature is 1197°C, the time in the furnace is 205min, the rough rolling adopts 6-pass rolling, and the reduction rate of each pass is 15%, 16% , 18%, 21%, 26%, 29%, rolled to 56mm; the finish rolling is 7-stand hot continuous rolling, the finish rolling start temperature is 959°C, the finish rolling temperature is 778°C, and the billet thickness after finish rolling is 7.9mm; Cool to 502°C at a cooling rate of 23°C / s, air-cool for 1s, and then cool to 492°C at a cooling rate of 11°C / s for coiling.

[0053] After testing, the mechanical properties of the pipeline steel produced in this embodiment are: Rt0.5: 542MPa, Rm: 611MPa, A50: 33.5%, Rt0.5 / Rm: 0.8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charpy impact energy | aaaaa | aaaaa |

| Shock | aaaaa | aaaaa |

| Charpy impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com