Soft rock chamber floor heave treatment supporting structure and method based on prefabricated assembly type bottom arc plates

A prefabricated assembly and support structure technology, applied in underground chambers, installation of anchor rods, shaft equipment, etc., can solve problems such as overall deformation and damage of roadways, achieve optimized rock mass quality, convenient processing and assembly, and suppress floor drums Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

[0035] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

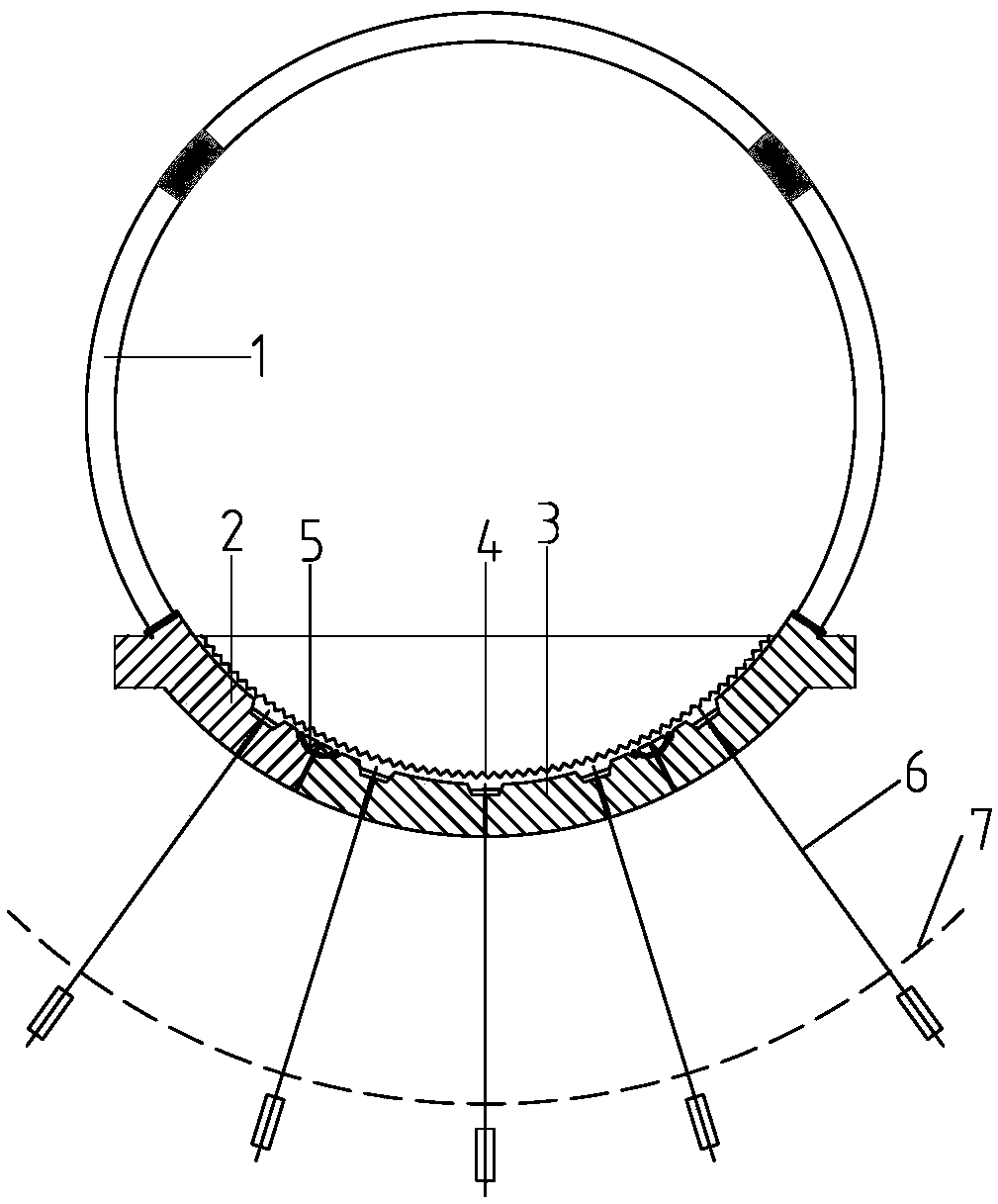

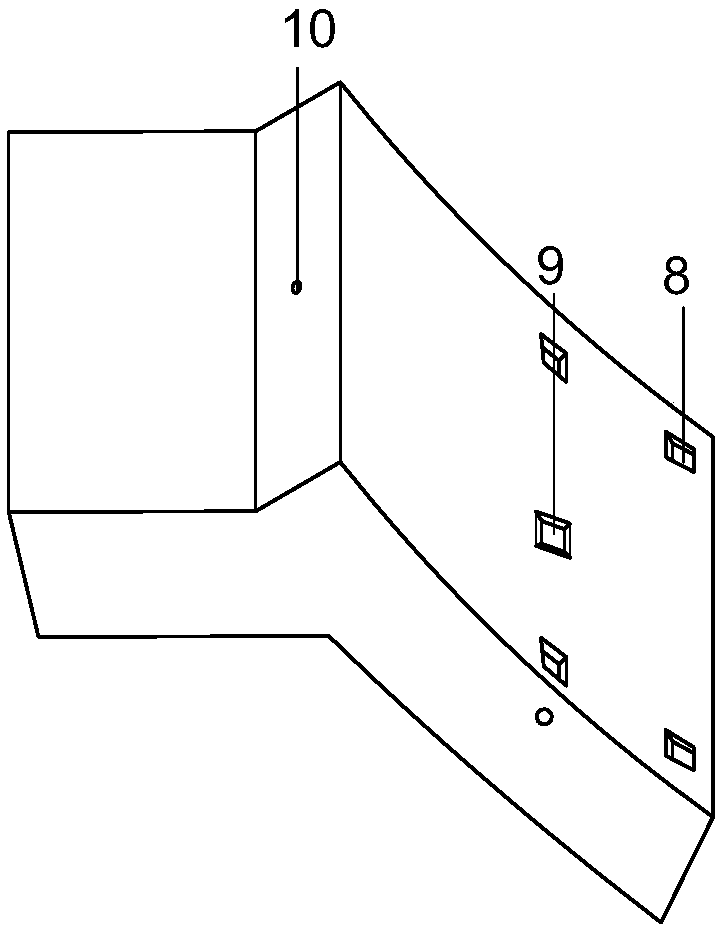

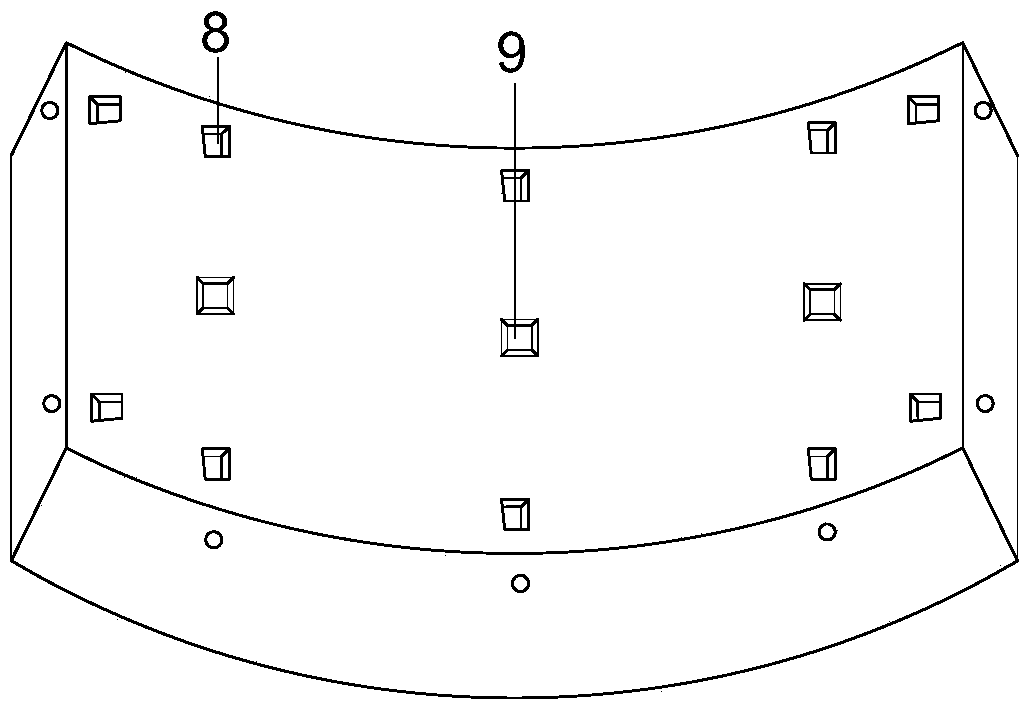

[0036] As shown in the figure, the main structure of the present invention is mainly composed of steel bracket 1, prefabricated assembled bottom arc plate 2, bottom control anchor cable 6 and bottom waterproof layer 4, in which the full-section optimized support technology is realized by high bearing capacity steel bracket 1 , The strengthened support technology of the bottom plate is realized by the combined support of prefabricated bottom arc plate + bottom control anchor cable 6 + bottom plate waterproof layer 4.

[0037] Specifically, a plurality of prefabricated assembled bottom arc plates are assembled to form a reinforced bottom plate, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com