Withdrawal working face flexible shield type reserved return air passage and manufacturing method thereof

A flexible shielding and return air channel technology, applied in tunnels, earthwork drilling, tunnel lining, etc., can solve problems such as easy blocking of solid return air channels, reduce labor intensity and cost input, ensure stability, and solve maintenance difficulties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

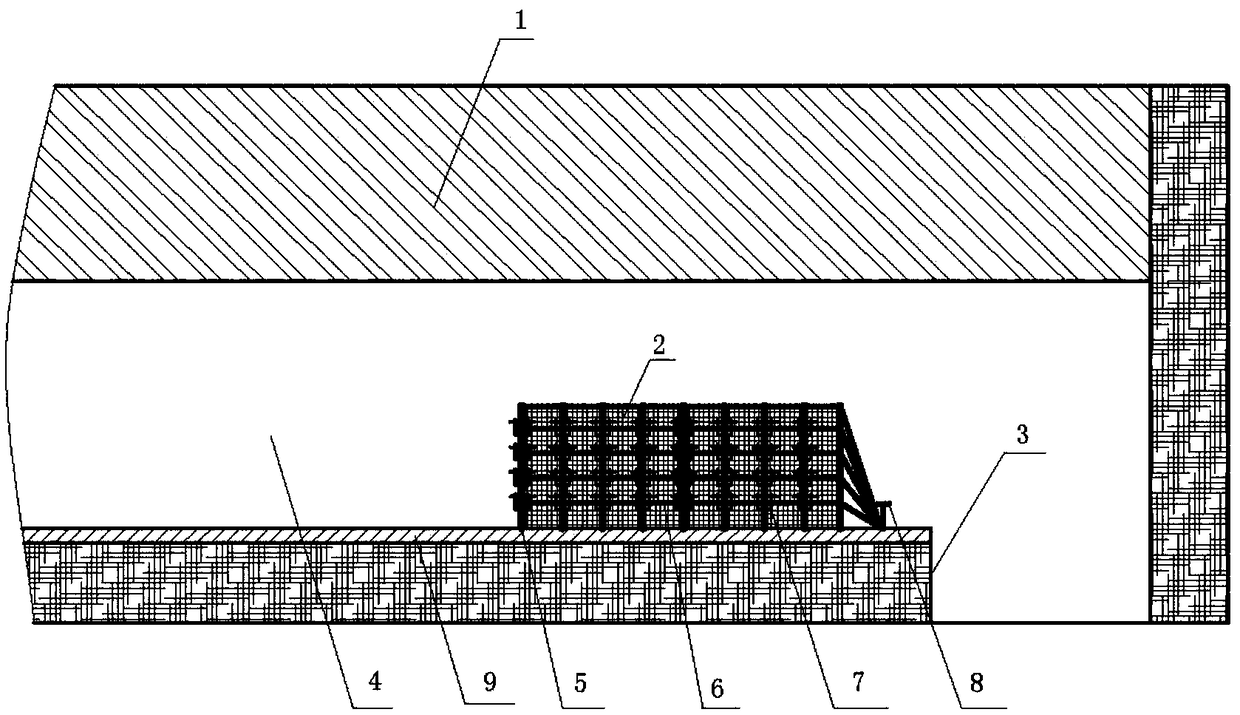

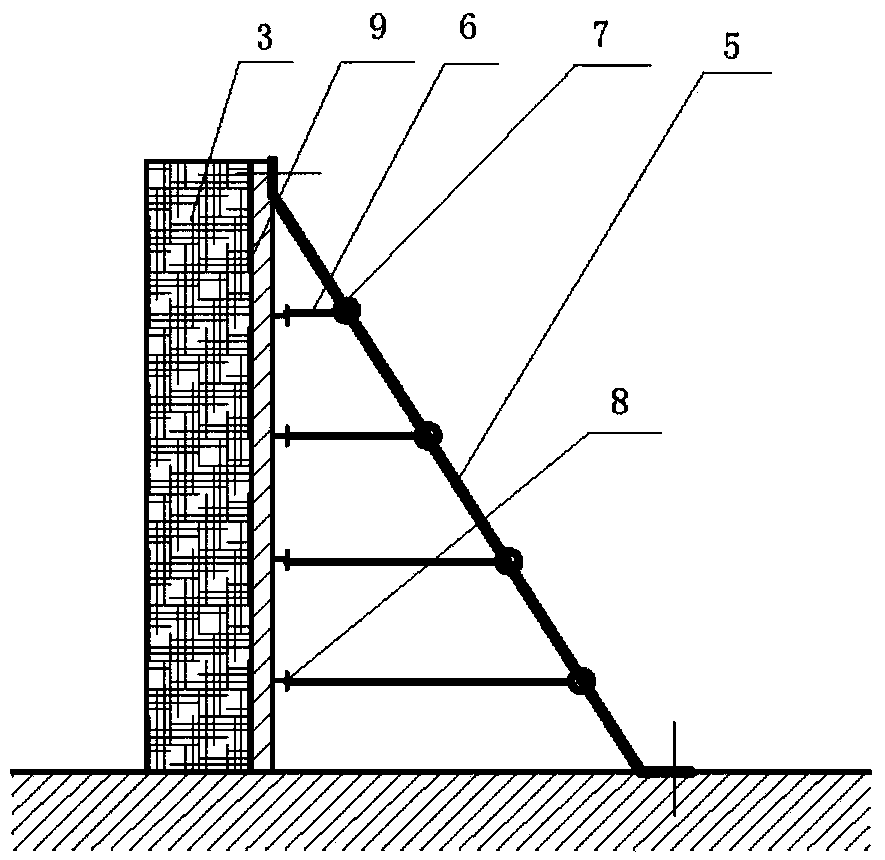

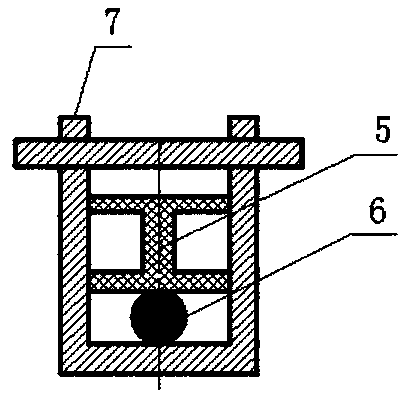

[0030] Such as Figure 1 to Figure 3 As shown, the flexible cover-type reserved return air channel for the retraction working face of the present invention includes: several I-beams 5, steel wire ropes 6, U-shaped clamps 7 and anchor nets 2, which are located on the working face 1 and the coal wall At the entrance between the retraction channels 4 between the 3, a support 9 is laid on the coal wall 3, and the upper end of each I-beam 5 is fixed on the support 9 of the coal wall 3, and each I-beam 5 The lower end is fixed on the ground of the withdrawal channel 4, the angle between each I-beam 5 and the coal wall 3 is 30°-45°, and the distance between adjacent I-beams 5 is 300-1000mm for each I-beam 5 are parallel to each other, and are connected with several steel wire ropes 6 on the outside of each I-beam 5, and one end of the steel wire rope 6 is connected with the outermost I-beam 5, and the steel wire rope 6 passes through each I-beam 5, and each steel wire rope 6 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com