Electrostatic dust collection double-layer sheet ventilation curtain wall

An electrostatic precipitator and curtain wall technology, applied to external electrostatic separators, walls, buildings, etc., can solve problems such as immature technology, poor indoor air quality, and inability to realize sunshade functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

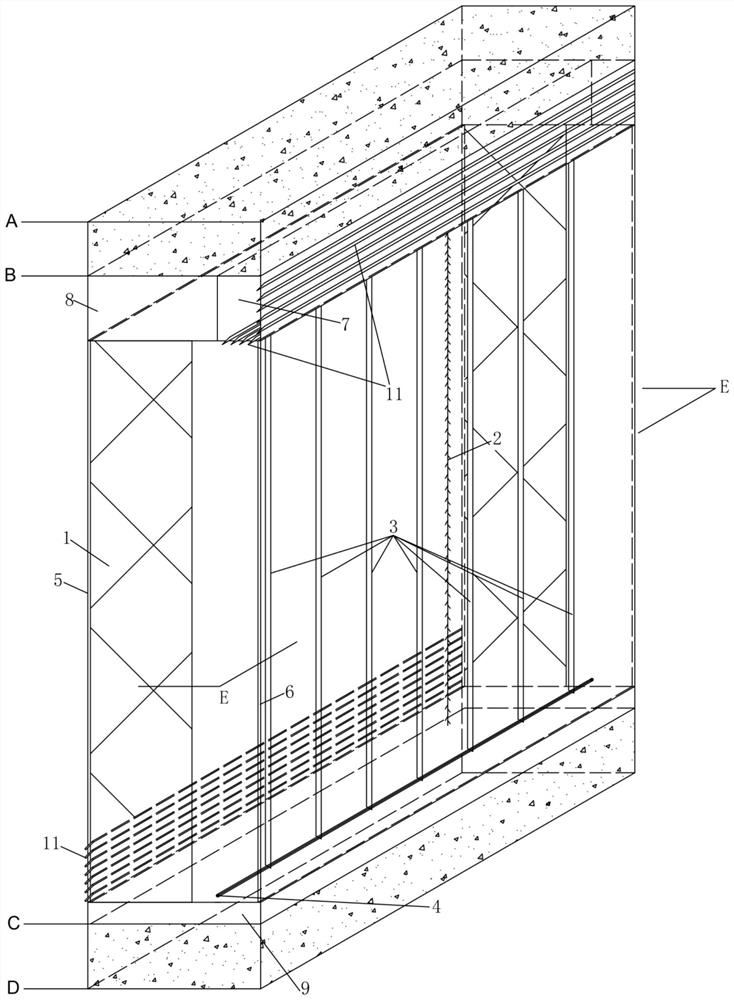

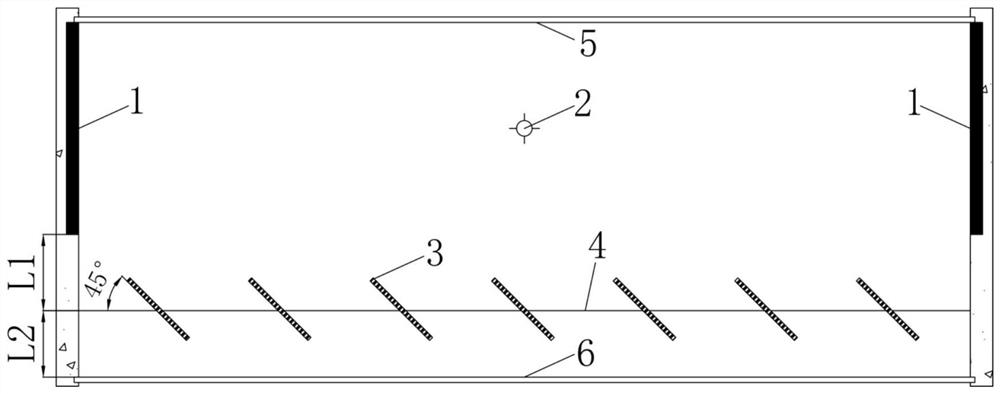

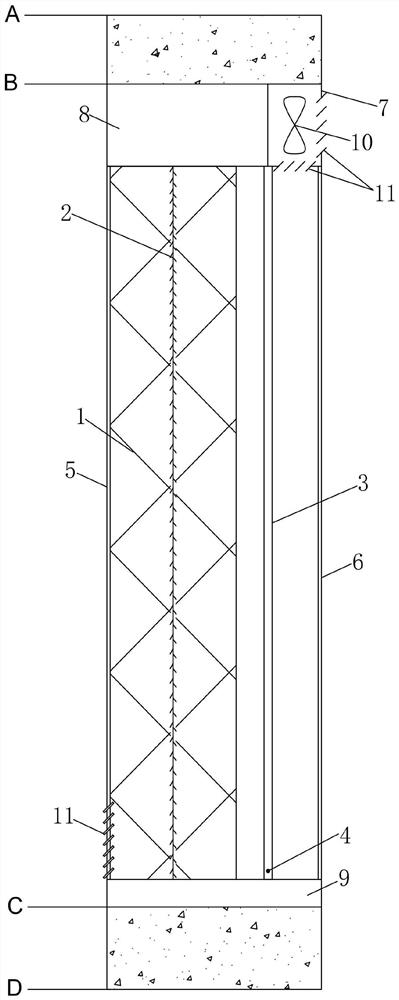

[0028] Referring to Figures 1-5, an electrostatic dust removal double-skin ventilated curtain wall is characterized in that positive plates 1 are provided on both sides of the curtain wall, and the outer surface is the outer skin 5 of the double-skin curtain wall. The lower part of the skin 5 is provided with a lower vent with a louver deflector 11, the inner surface of the curtain wall is the inner skin 6 of the double-layer leather curtain wall, and the gap between the outer skin 5 of the double-layer leather curtain wall and the inner skin 6 of the double-layer leather curtain wall The cavity in the cavity forms an air channel; one or more corona wires 2 with thorns are provided as negative poles in the cavity, and a row of lower shafts is also provided on the side of the cavity close to the inner skin 6 of the double-layer leather curtain wall. 4 driven rotatable louver dust collection plate 3; the lower part of the curtain wall is provided with a dust collection tank 9, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com