Leveling system for self-adaptive chassis leveling of high-ground-clearance plant protection machine

A plant protection and self-adaptive technology, applied in mechanical equipment, fluid pressure actuating devices, servo motors, etc., can solve the problems of high precision requirements, large height difference, and high cost, and achieve guaranteed operation results and low precision requirements. , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of the present invention, the present invention will be described more fully and in detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

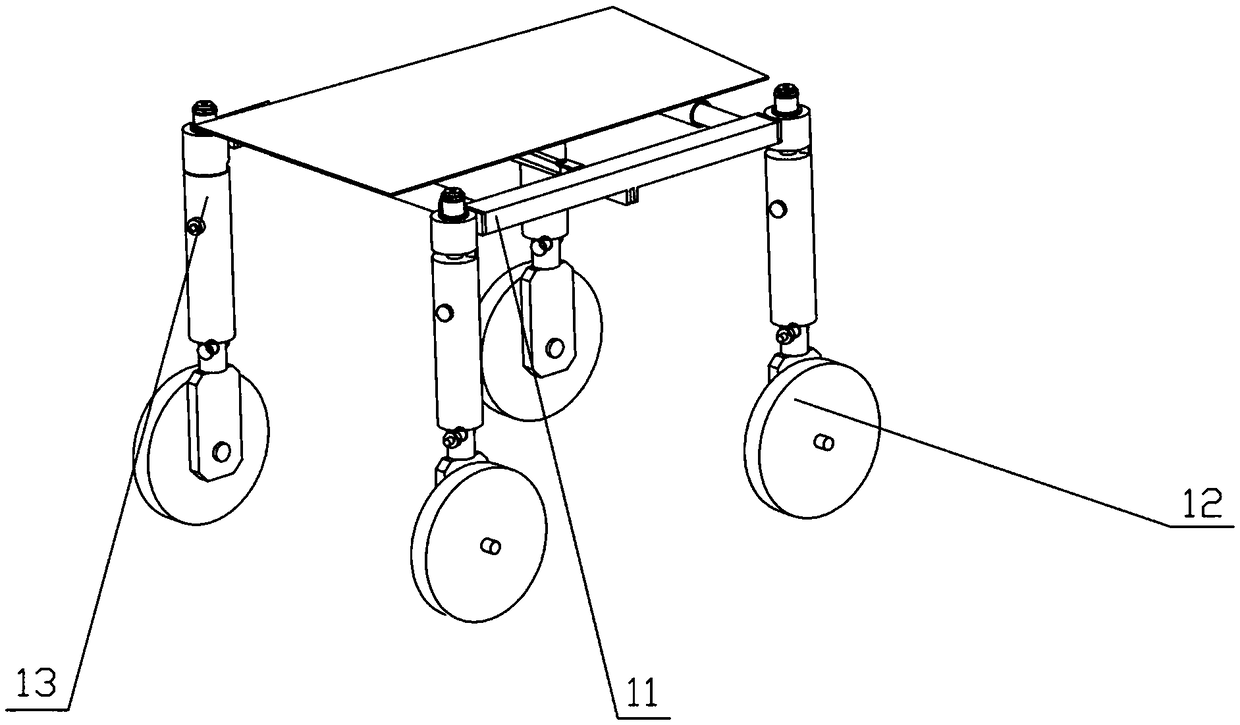

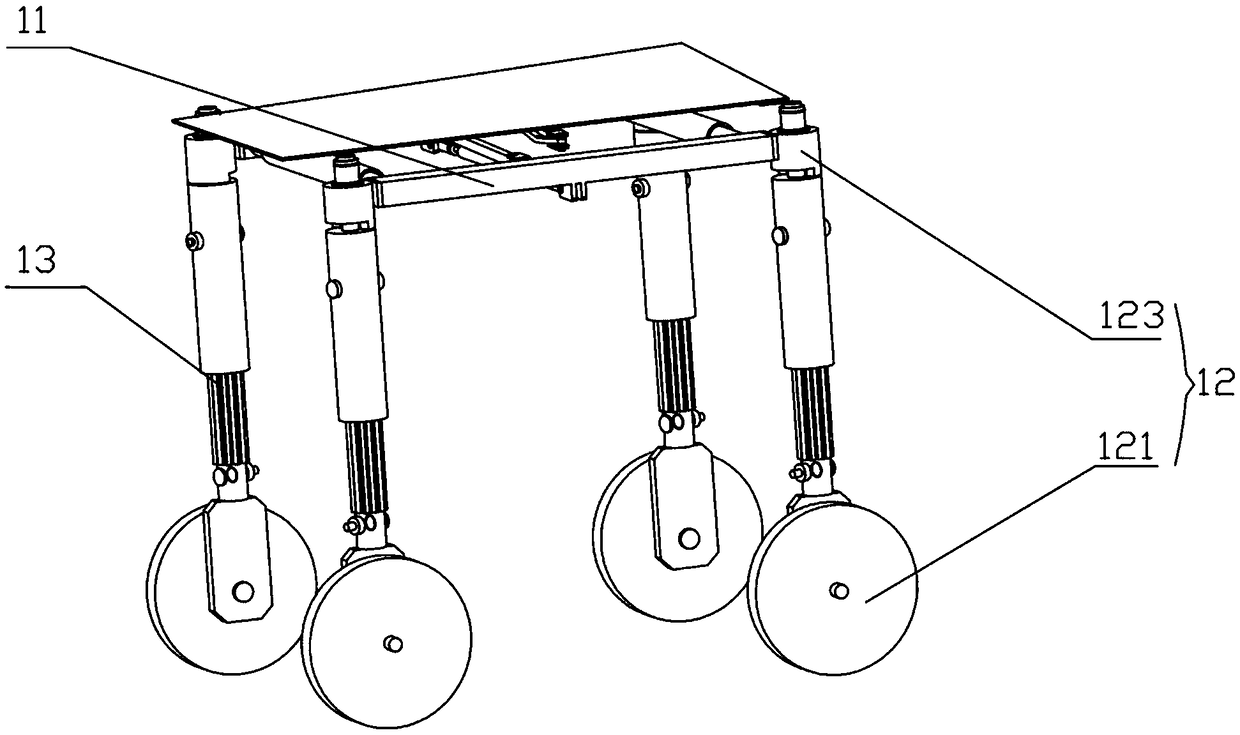

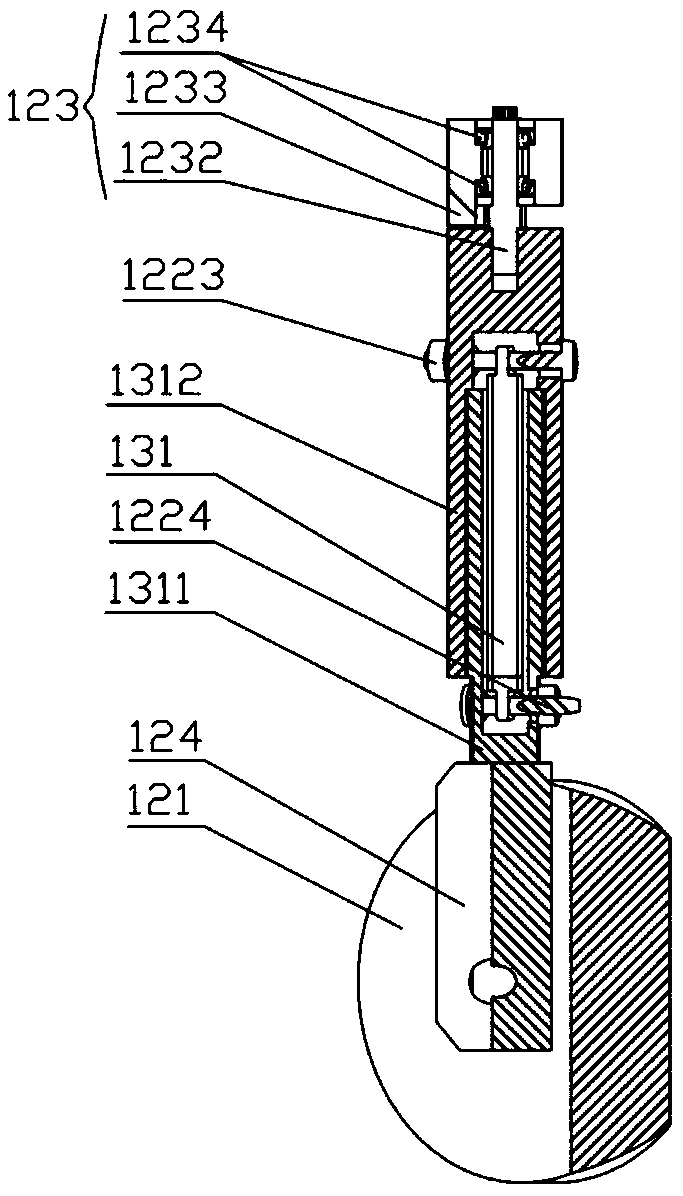

[0026] Such as Figure 1 to Figure 5 As shown, a leveling system for self-adaptive leveling chassis of a plant protection machine with high ground clearance includes a frame body 11 for supporting the plant protection machine, four independently driven traveling mechanisms 12 installed and fixed on the lower side of the frame body 11 and hydraulic pressure Leveling mechanism 13, the four traveling mechanisms 12 are distributed in four different directions of the frame body 11, each hydraulic leveling mechanism 13 includes a lifting tube 131 and is used to control the expansion and contraction of the lifting tube 131 and has two oil inlets and outlets. Lifting...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap