Combined elastic ring type extrusion oil film damper

A technology of squeezing oil film damping and elastic ring, applied in the direction of spring/shock absorber, spring, shock absorber, etc., can solve problems such as uncoordinated precession, large vibration of rotor system, fatigue, etc. good vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

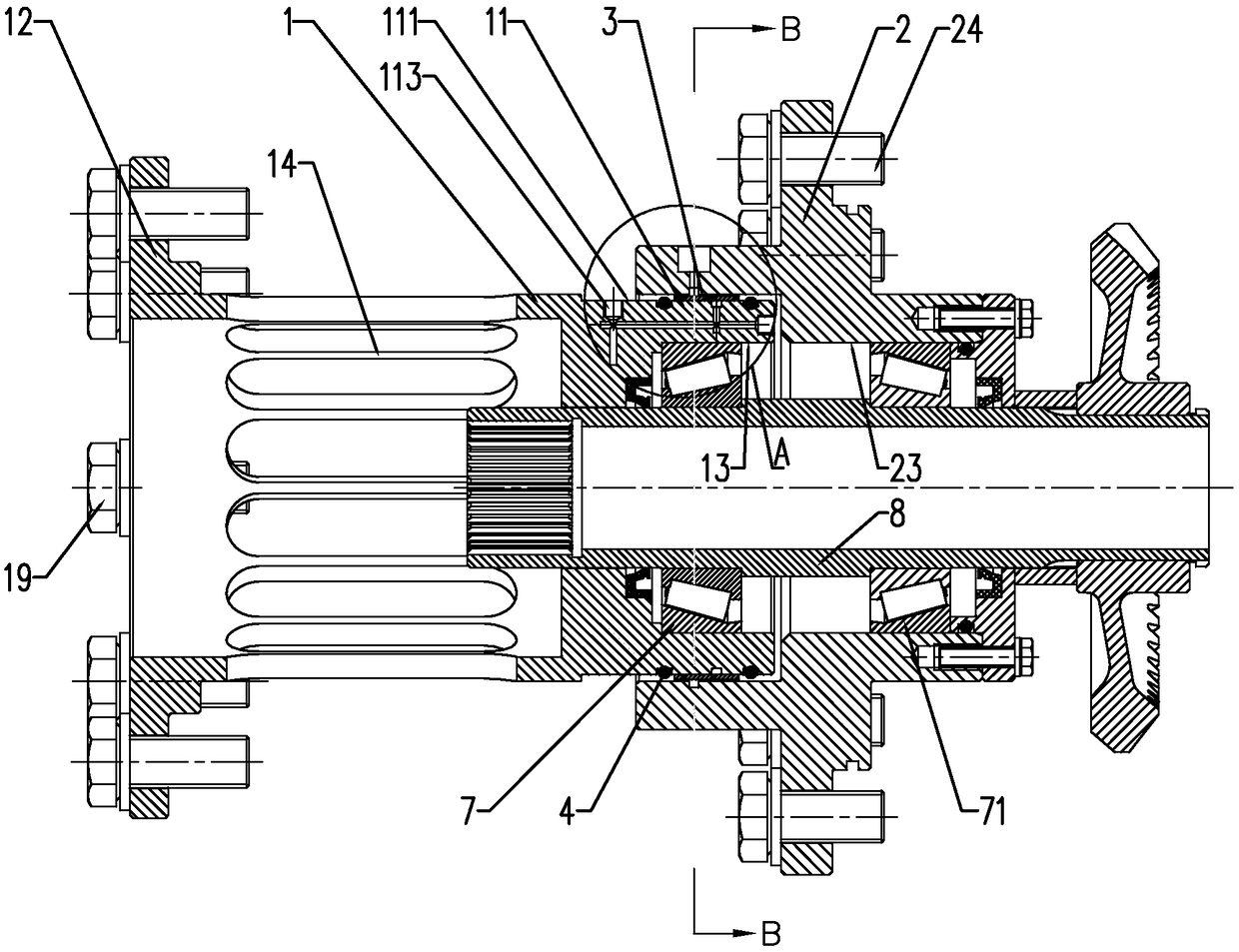

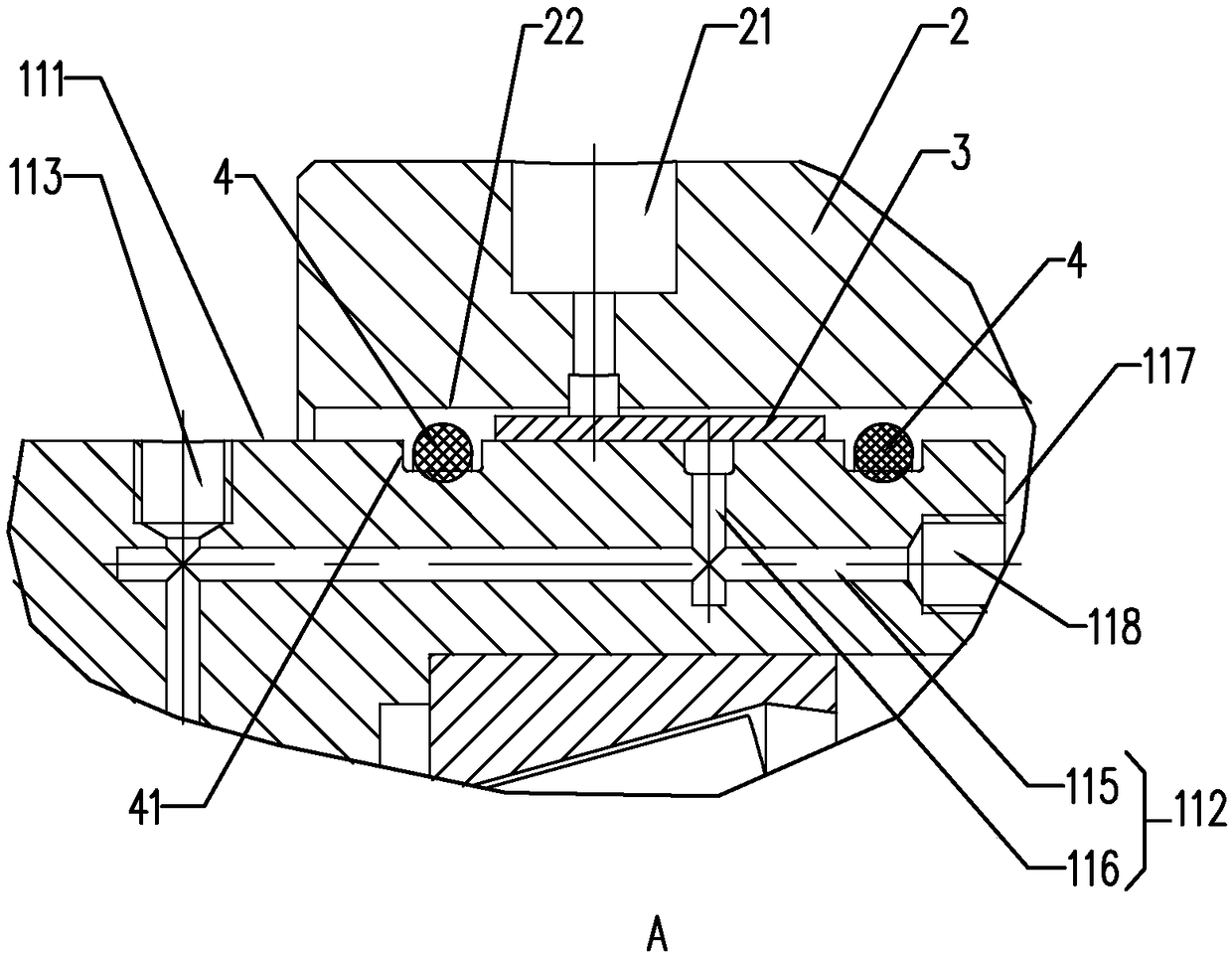

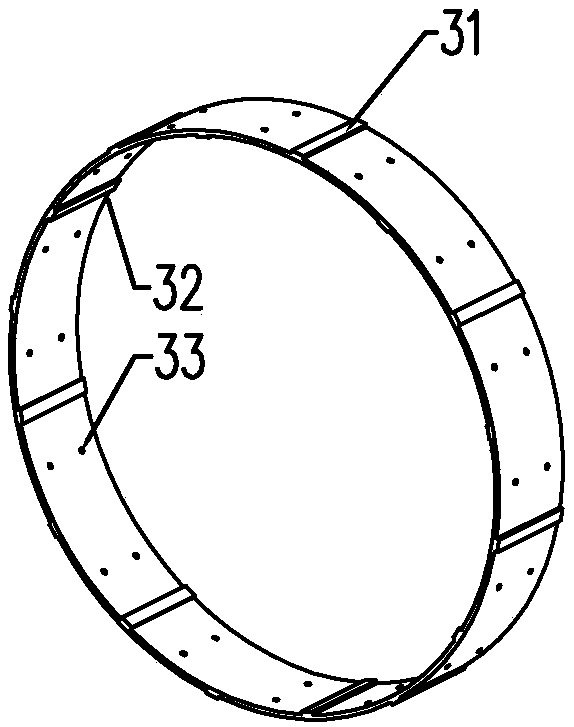

[0031] Such as figure 1 , figure 2 and image 3 As shown, a combined elastic ring squeeze oil film damper includes an elastic support 1, a bearing seat 2 and an elastic ring 3; the elastic support 1 is used for fixed connection with the body (not shown in the figure), and the bearing seat 2 can Fixed on the machine body by bolts 24, the elastic support 1 provides positioning for the main shaft 8 through the bearing 7, the bearing 7 can be a roller bearing, the elastic support 1 includes a positioning end 12 for fixed connection with the body, and a cantilever end away from the positioning end 12 11. Oil return channel 112 and oil return port 113; the positioning end 12 can be fixed on the body through the screw 19 in the middle, and at least one oil inlet 21 is provided on the bearing seat 2 as an oil inlet, and the bearing seat 2 is set There is an inner ring surface 22 for assembling with the elastic support 1; several outer bosses 31 are arranged on the outer peripheral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com