Calibration plate with high-precision and low-cost for visible/infrared camera calibration and calibration method thereof

A technology of infrared cameras and calibration plates, applied in chemical instruments and methods, applications, household appliances, etc., can solve the high difficulty of infrared suppression coating application process, difficult to obtain accurate feature point positions, blurred boundaries of feature areas, etc. problems, to achieve the effect of small thermal deformation, easy access and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described in further detail below in conjunction with the accompanying drawings.

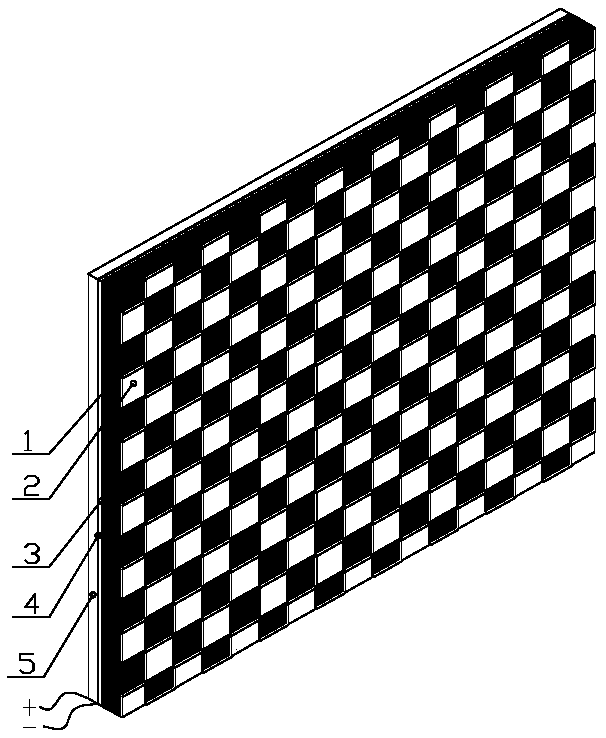

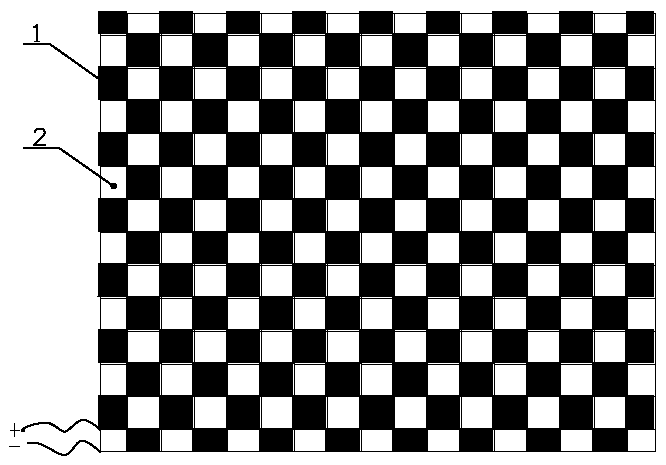

[0026] Such as figure 1 It is a three-dimensional diagram of a calibration plate suitable for a visible light / infrared camera of the present invention, including a substrate 1 , a laying layer 2 , a transition layer 3 , a heating layer 4 , and a thermal insulation layer 5 .

[0027] Among them, the laying layer 2 is bonded to the front of the substrate 1; the transition layer 3 is installed on the back of the substrate 1, and the thermal conductive silicone grease is filled between the substrate 1 and the transition layer 3; the heating layer 4 is attached to the back of the transition layer 3; the heat preservation layer 5 Attached to the back of the heating layer 4, and fixed with the transition layer 3.

[0028] The substrate 1 is made of an aluminum alloy material with excellent thermal conductivity, and its size is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com