Plate bottom flexural-tensile stress monitoring system and method for existing runway surface structure

A technology of stress monitoring and bending and pulling, which is applied in the direction of measuring, measuring force, and measuring devices by measuring the change in optical properties of materials when they are stressed, can solve problems such as damage, high cost, and difficulty, and achieve high detection accuracy , fast speed and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The device and method for monitoring bending and tension stress at the bottom of the slab bottom for existing pavement structures provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

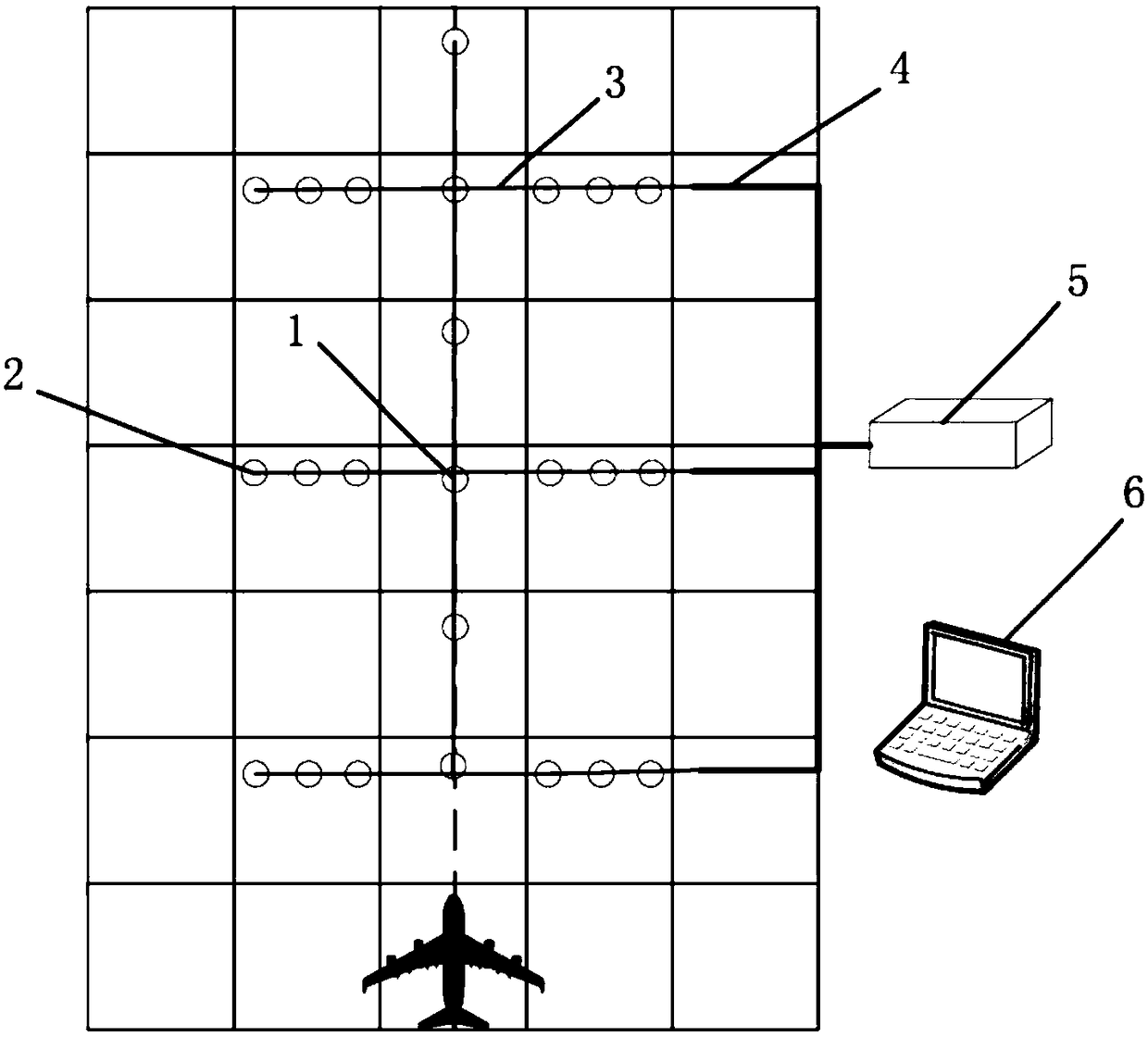

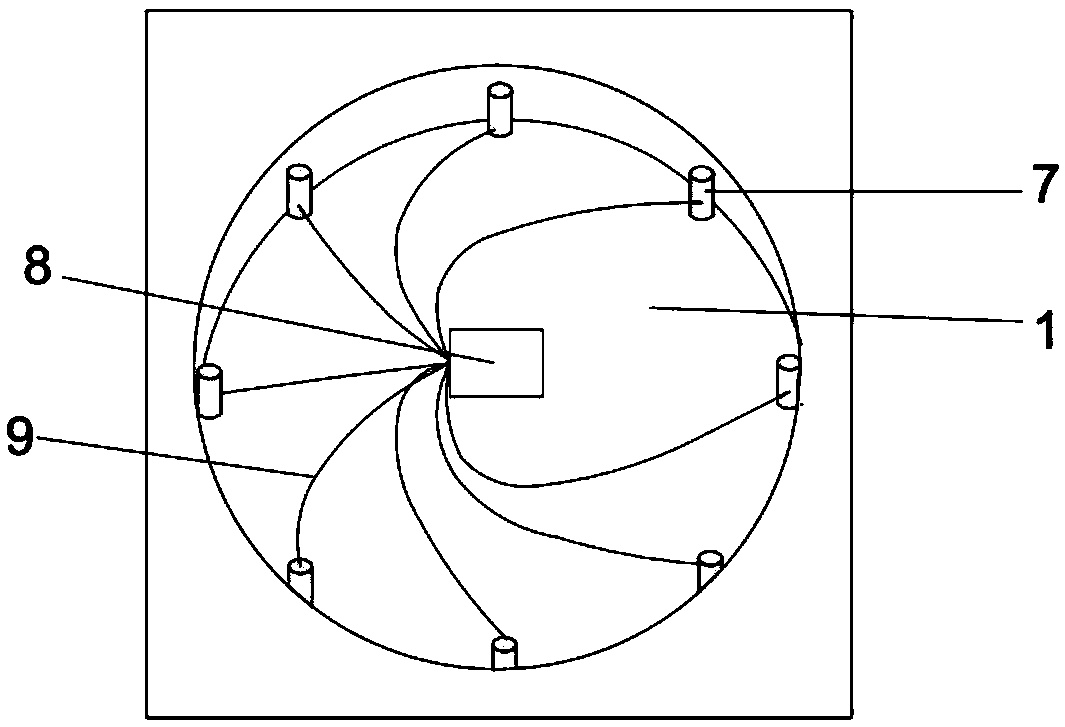

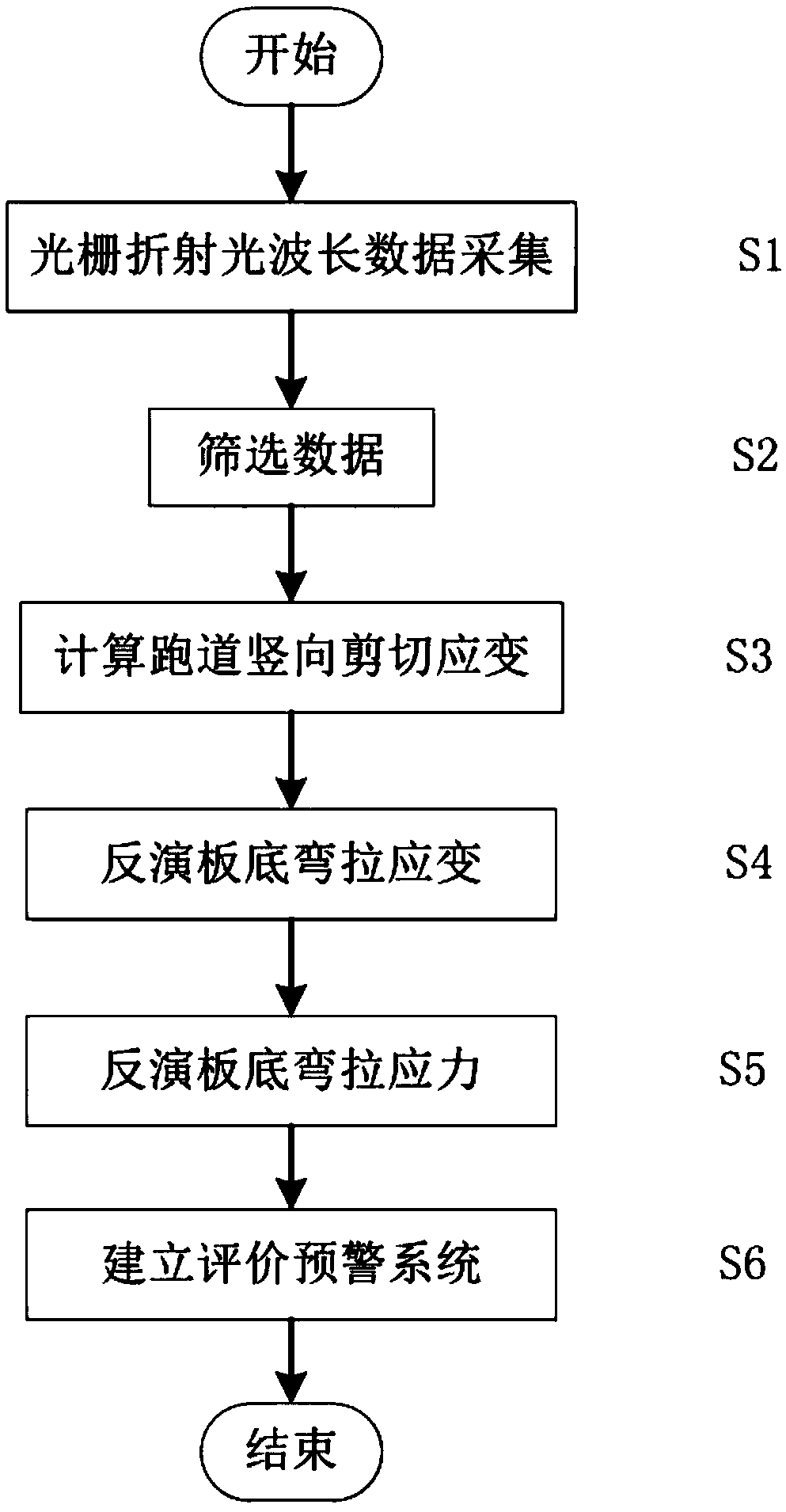

[0012] like figure 1 — figure 2 As shown, the bending-tensile stress monitoring device for the bottom of the existing pavement structure provided by the present invention includes a plurality of fiber grating sensors 7, armored optical fibers 3, Main optical cable 4, fiber grating demodulator 5, main control terminal 6, splitter 8, optical fiber jumper 9 and temperature-compensated grating sensor; wherein each runway centerline lighting hole 1 and the grounding belt lighting hole 2 are separated on the side wall A plurality of fiber grating sensors 7 are installed at a distance, and are respectively connected to the output end of the splitter 8 through an optical fiber jumper 9 to form a test group; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com