Device for detecting unburned carbon in flue dust of boiler

A fly ash carbon content and detection device technology, applied in the direction of weighing by removing certain components, can solve problems such as poor measurement accuracy, and achieve the effects of improving accuracy, strong representation, and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

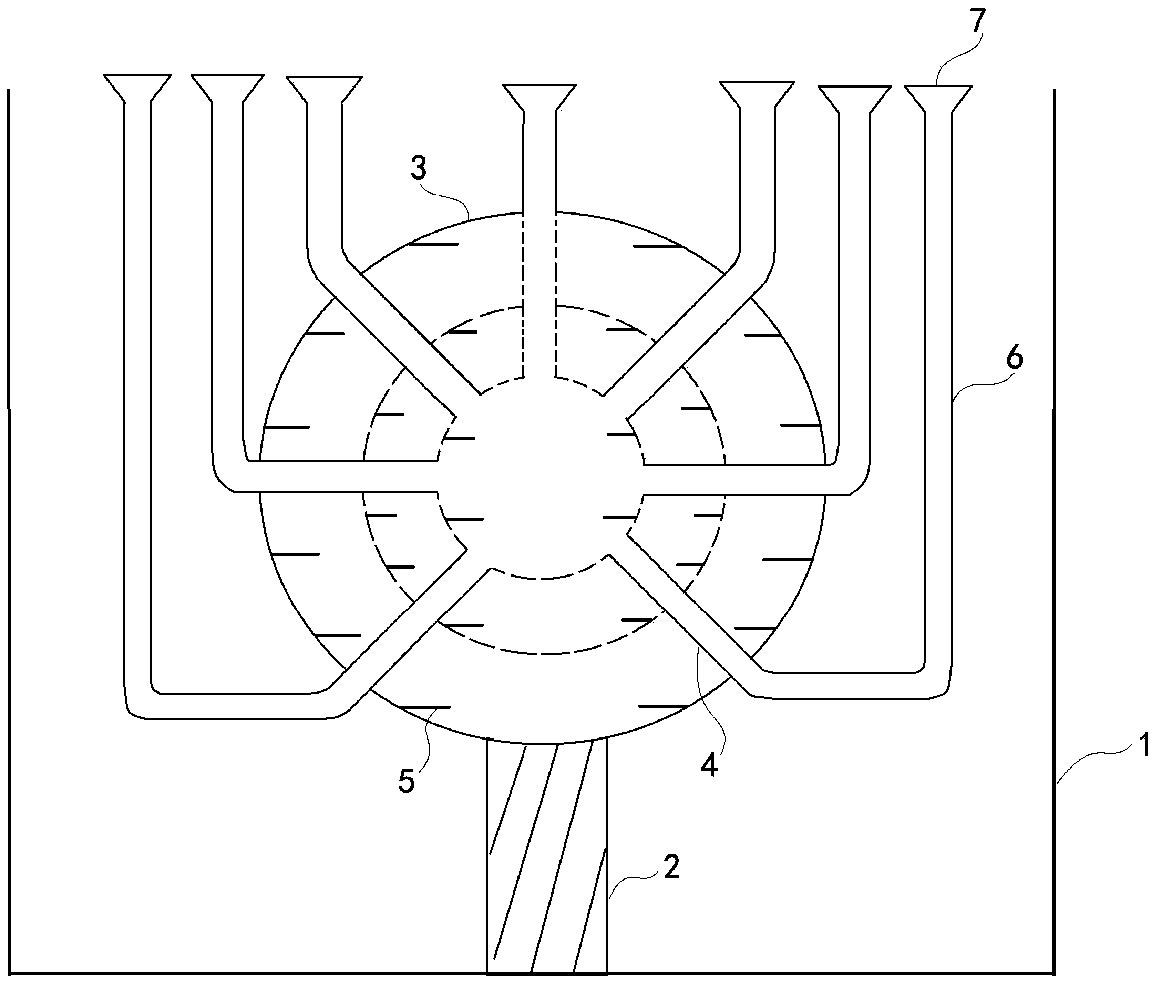

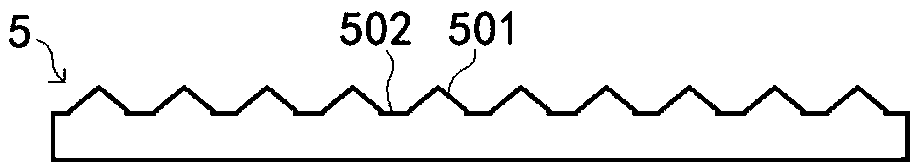

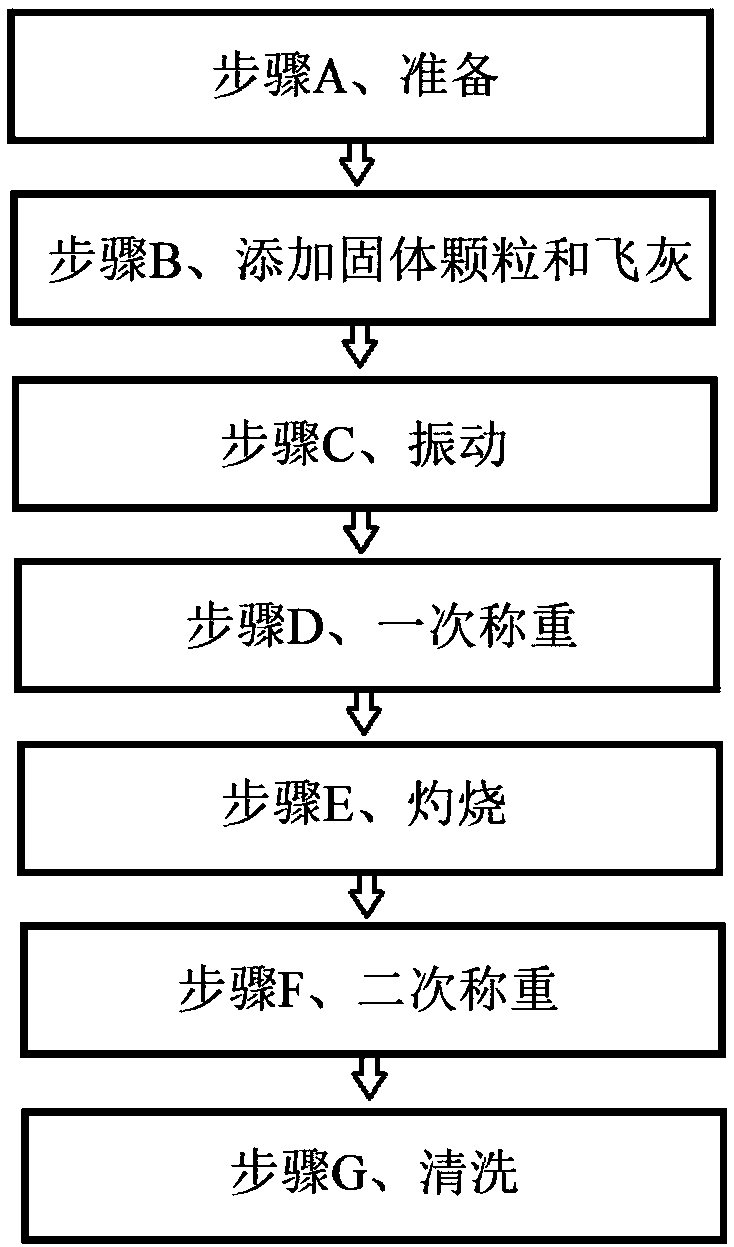

[0030] refer to Figure 1-2 , The boiler fly ash carbon content detection device of this embodiment includes a storage container 1, and the storage container 1 is provided with a burning mechanism for storing fly ash and burning the fly ash. Wherein, the burning mechanism includes: several burning spherical shells 3 nested in sequence (specifically, in this embodiment, three burning spherical shells 3 nested in sequence, that is, three sets of burning spherical shells in the outermost layer) Outside the burning spherical shell 3 of the middle layer, the burning spherical shell 3 of the middle layer is set on the outside of the innermost burning spherical shell 3) and several connecting cylinders 4, the bottom end of the outermost burning spherical shell 3 Connected to the bottom of the storage container 1 through the support column 2, the shape of the burning spherical shell 3 is a hollow sphere, wherein all the burning spherical shells 3 inside the outermost burning spherical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com