Indoor sand grouting simulation test device and testing method thereof

A simulation test and grouting technology, applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve the problems of backwardness, limited improvement space, reduce the permeability coefficient of sandy soil layers, etc., and achieve the effect of optimizing grouting parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

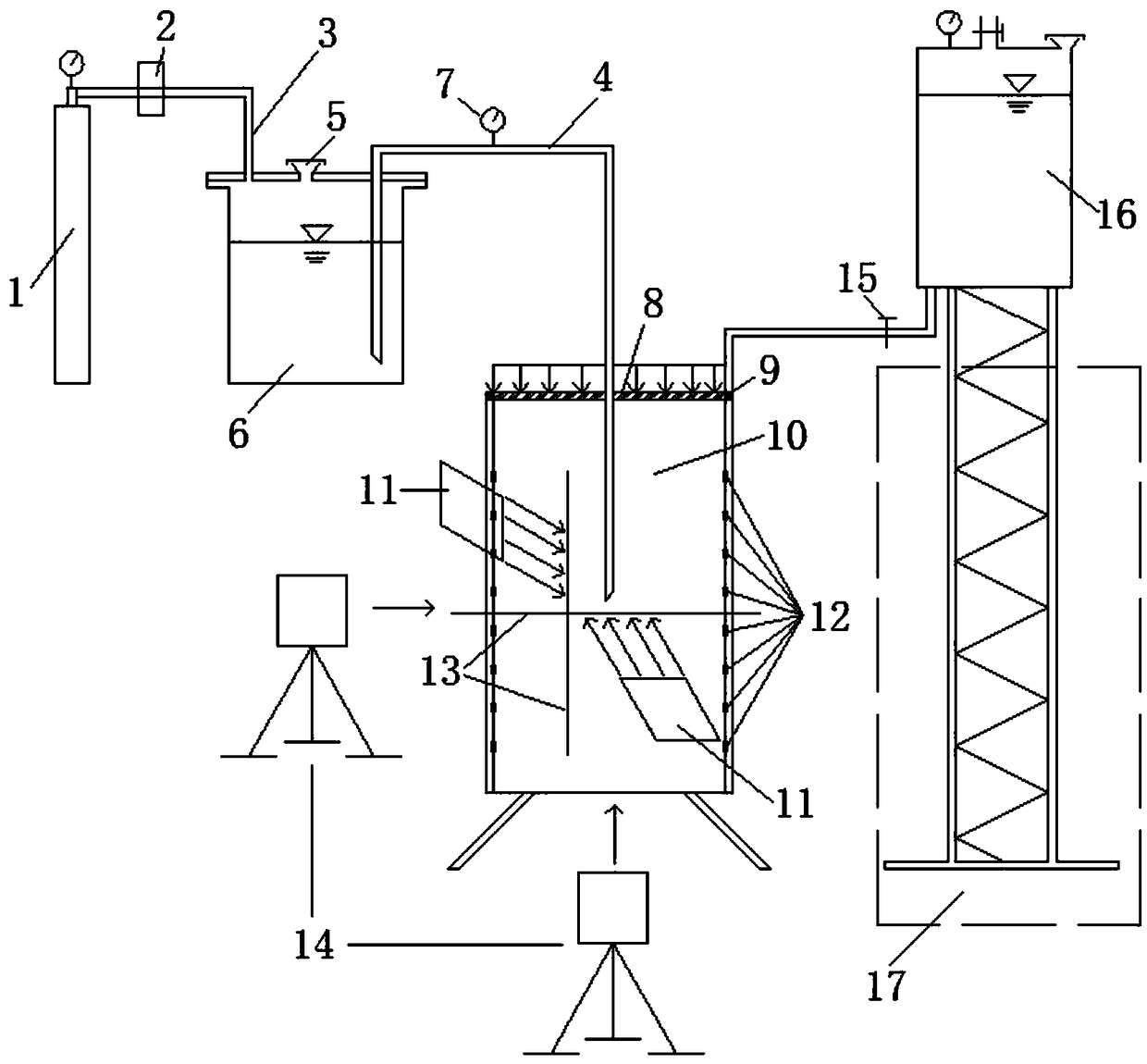

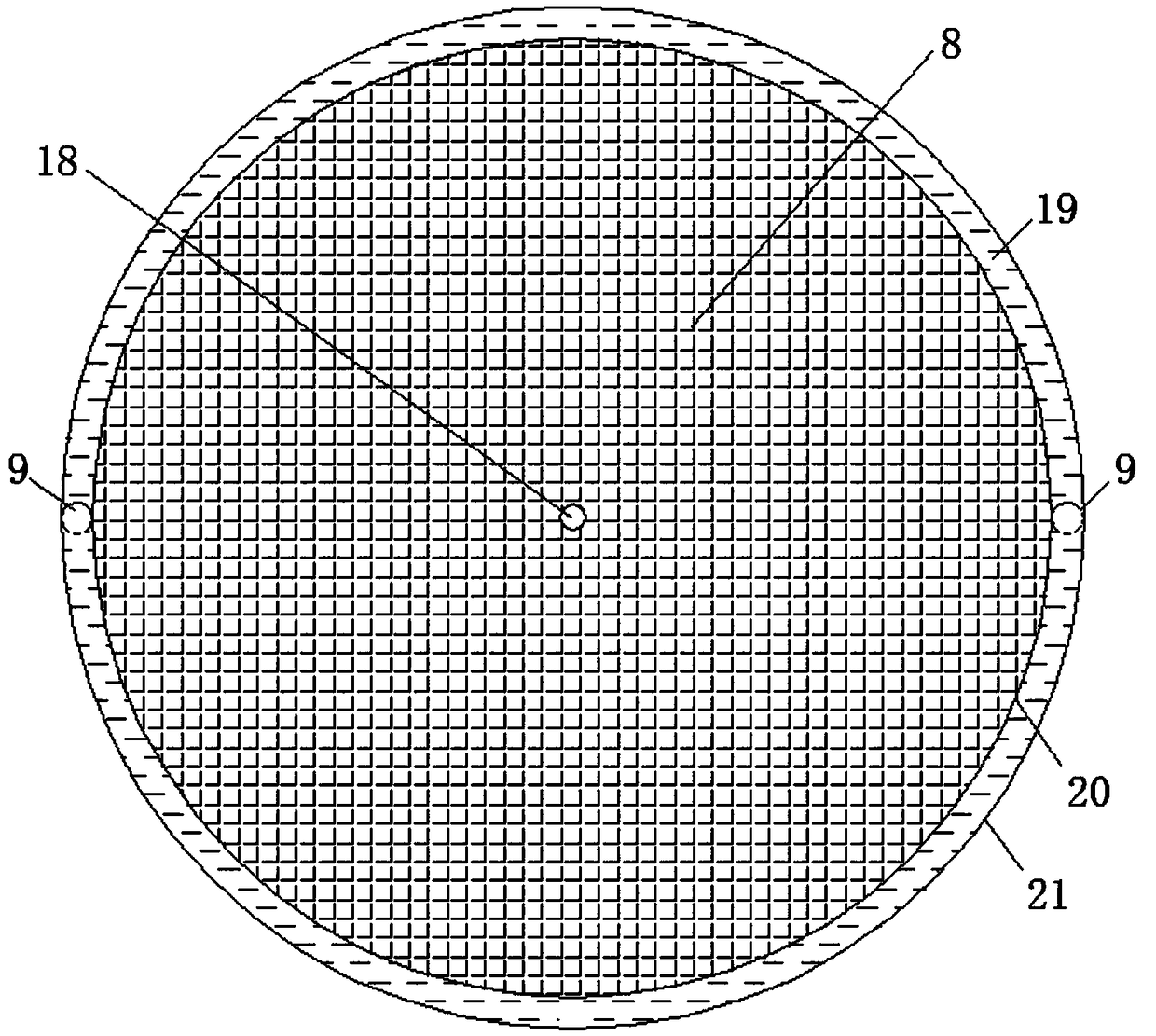

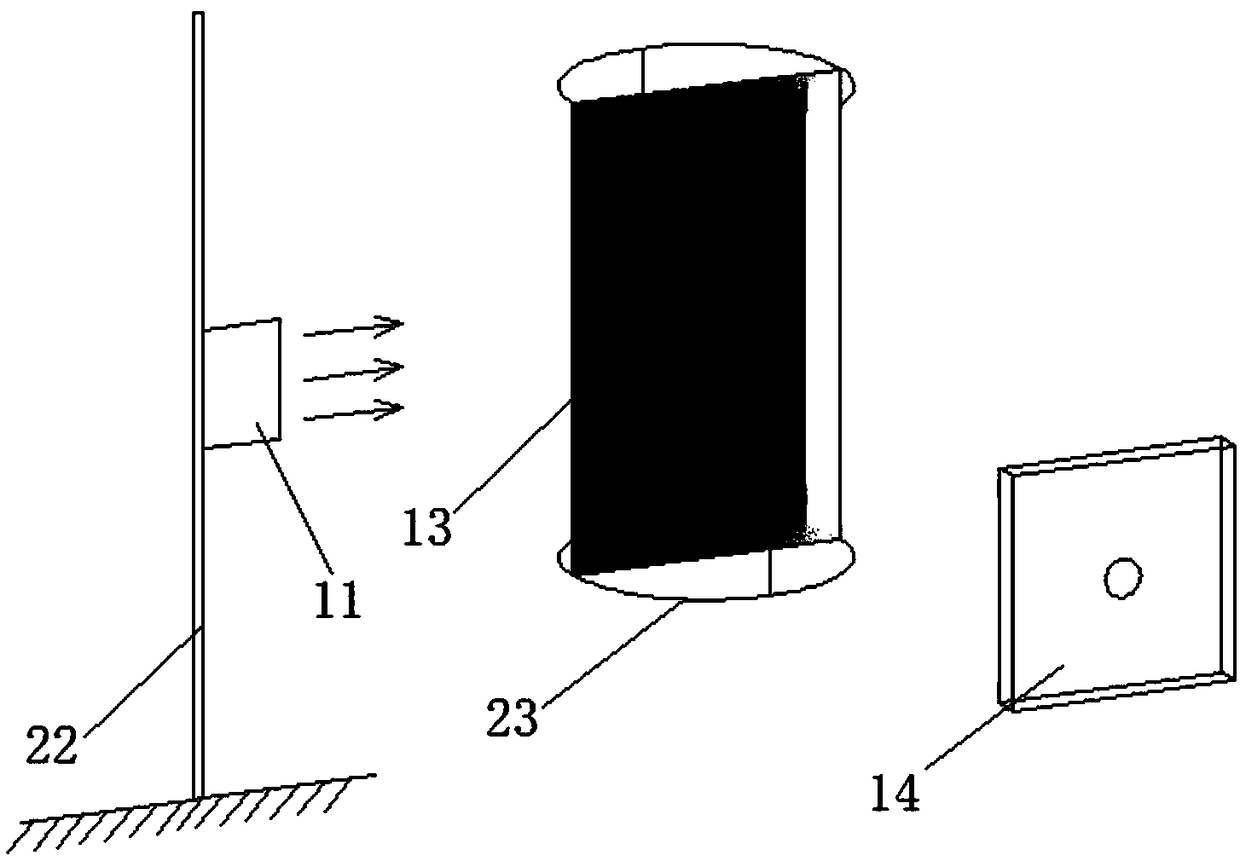

[0042] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0043] At present, traditional indoor sand grouting experimental research equipment is difficult to capture the flow pattern of grouting slurry in the process of sand grouting, and it is even more difficult to reproduce the behavior of sandy soil under different grout pressures, different groundwater pressures, and different ground stresses. Movement characteristics, therefore, research on indoor sand grouting tests is still relatively abstract. In order to truly reflect the movement characteristics of sand and soil during the grouting process and reproduce the movement and diffusion process of grouting grout, the present invention introduces a newly developed test device and its test method for simulating indoor sand and soil grouting. The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com