On-site metallographic replica method

An on-site, methyl violet technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of damaged AC paper, affecting the use of AC paper, and the tight fit between AC paper and the detection surface, etc., and achieves the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

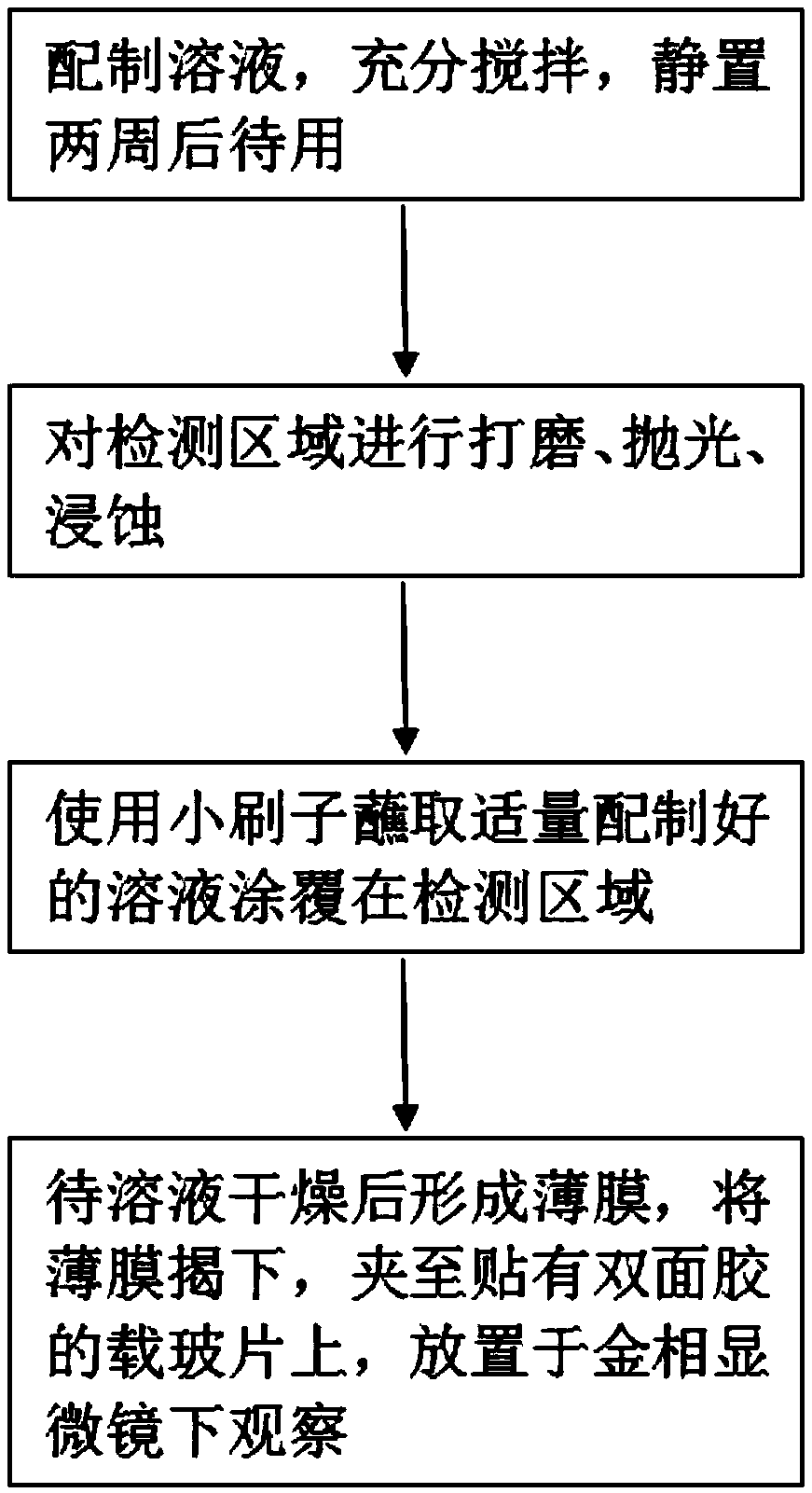

Method used

Image

Examples

Embodiment 1

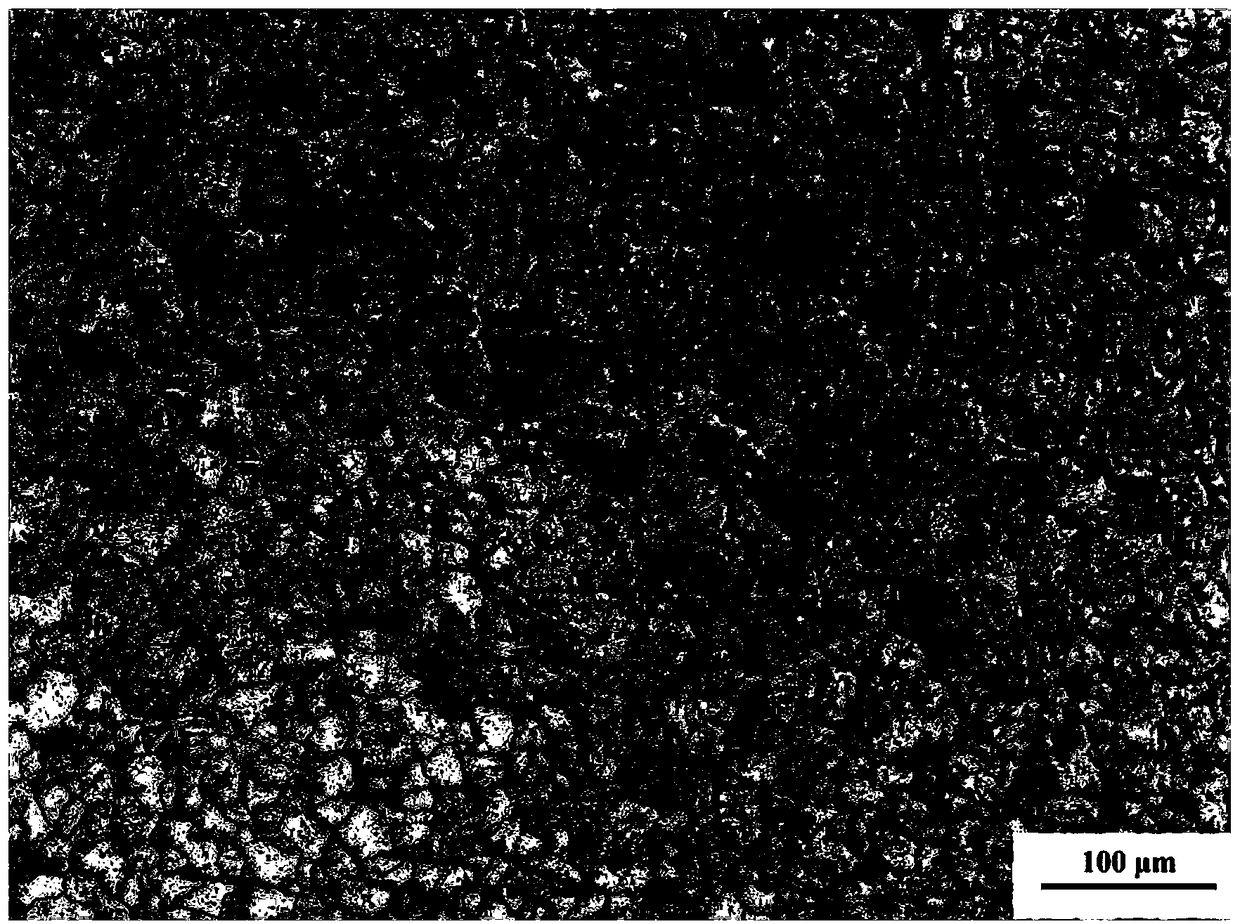

[0039] The metallographic production of the metallographic sample of the rear screen superheater tube of a power plant boiler made of 12Cr1MoV and the specification of Φ54×9mm was carried out. The operating time was about 192,000 hours. The specific process was as follows:

[0040] 1) Weigh acetone, methyl violet, cellulose acetate and triphenyl phosphate, then stir and mix the acetone, methyl violet, cellulose acetate and triphenyl phosphate to obtain a mixed solution, wherein acetone, methyl violet, The ratio of cellulose acetate and triphenyl phosphate is 500mL: 0.5~2g: 10~40g: 5~15g;

[0041] 2) Grinding, polishing and etching the area to be tested. Specifically, use #120, #240, #400, #600, #1000 sandpaper to polish in sequence, and then use 10 μm and 5 μm polishing paste to polish respectively, and then use 4 % nitric acid alcohol solution for etching;

[0042] 3) Apply the mixed solution obtained in step 1) to the area to be detected, dry to form a film, then remove the...

Embodiment 3

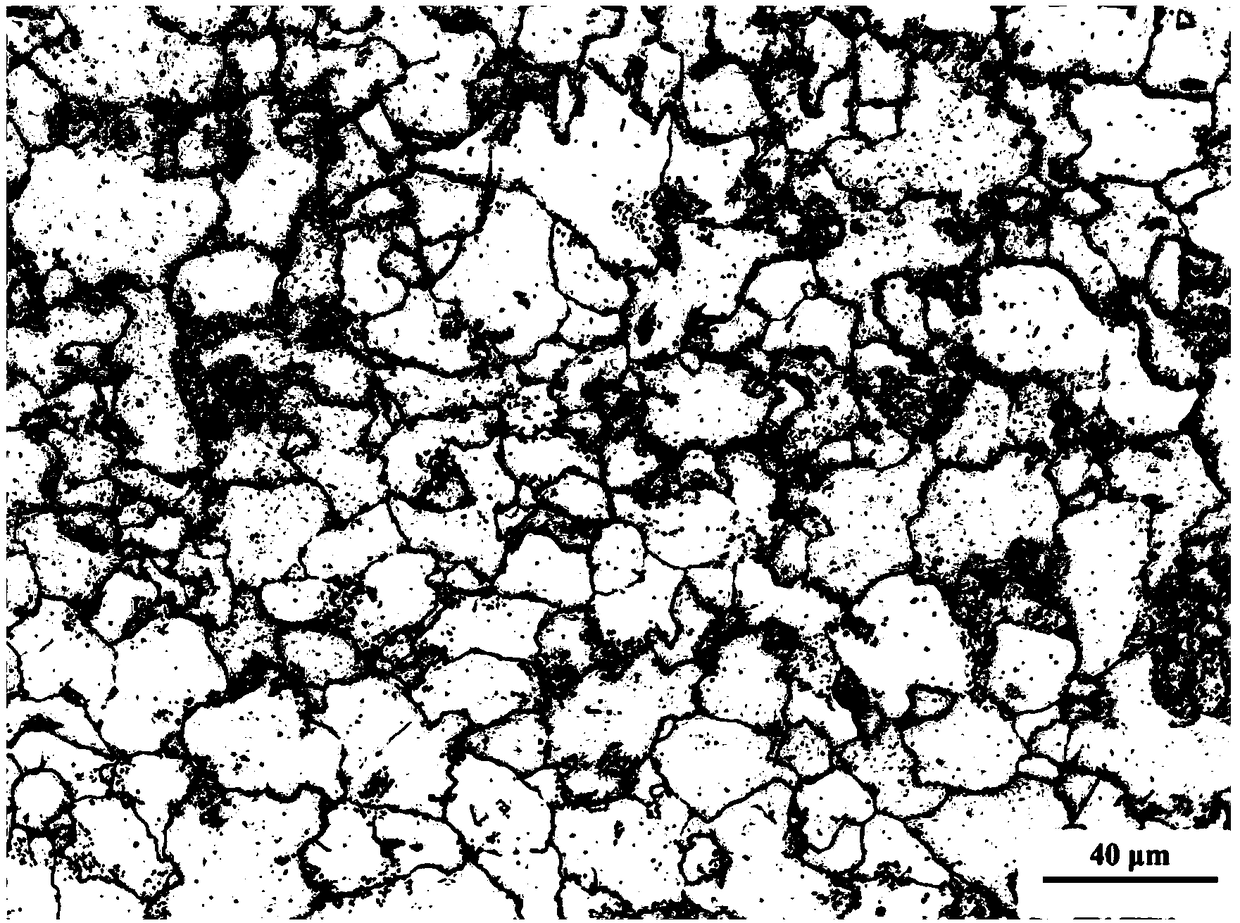

[0053] The metallographic production of a metallographic sample of a high-temperature superheater tube with a material of TP304H and a specification of Φ54×9mm in a power station boiler was carried out. The operating time was about 192,000 hours. The specific processing process was as follows:

[0054] 1) Weigh acetone, methyl violet, cellulose acetate and triphenyl phosphate, then stir and mix the acetone, methyl violet, cellulose acetate and triphenyl phosphate to obtain a mixed solution, wherein acetone, methyl violet, The ratio of cellulose acetate and triphenyl phosphate is 500mL: 0.5~2g: 10~40g: 5~15g;

[0055]2) Grinding, polishing and etching the area to be tested. Specifically, use #120, #240, #400, #600, #1000 sandpaper for grinding, and then polish with 10 μm and 5 μm polishing paste respectively, and then use Kai Lynn reagent for etching;

[0056] 3) Apply the mixed solution obtained in step 1) to the area to be detected, dry to form a film, then remove the film, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com