Method for preparing ZIF-67 polyhedron to obtain velvet hollow polyhedron Co9S8 <at> MoS2

A technology of ZIF-67 and polyhedron, which is applied in the field of preparation of hollow polyhedron Co9S8@MoS2, can solve the problems of poor charge and discharge performance, and achieve the effect of improving crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation of α-CoS hollow polyhedron

[0028] Co(NO 3 ) 2 ·6H 2 O 291 mg and 2-methylimidazole 328 mg were dissolved in 25 ml methanol solution and mixed, stirred at room temperature for 24 h, after the reaction was over, centrifuged at 6000 rpm for 5 min, washed with ethanol 4 times, and obtained the solid phase at 60 After drying at ℃ for 6 h, ZIF-67 nano-polyhedrons were formed.

[0029] Take 30 mg of ZIF-67 nano polyhedron and disperse it in 30 ml ethanol solution ultrasonically, add 150 mg of thioacetamide and react at 40°C for 24 h. After the reaction is over, centrifuge at 5000 rpm for 5 min, and wash with water and ethanol 3 Next, a hollow α-CoS polyhedron with a shell thickness of 40 nm was obtained.

[0030] The made α-CoS hollow polyhedron has a particle size of about 300~600 nm. The middle part of ZIF-67 is completely etched to form a hollow structure of α-CoS polyhedron. The surface is flat and uniform, and the wall thickness is controlled at 15~ At 40 nm, ...

Embodiment 2

[0035] 1. Preparation of α-CoS hollow polyhedron

[0036] Co(NO 3 ) 2 ·6H 2 O 291 mg and 2-methylimidazole 656 mg were dissolved in 25 ml methanol solution and mixed, stirred at room temperature for 24 hours, after the reaction was over, centrifuged at 6000 rpm for 5 min, washed with ethanol 4 times, and obtained the solid phase at 60℃ Dry for 6 hours to form a ZIF-67 nano-polyhedron.

[0037] Take 30 mg of ZIF-67 nano polyhedron and disperse it in 30 ml ethanol solution ultrasonically, add 90 mg thioacetamide and transfer to a 50 ml high temperature and high pressure reactor, and react at 100℃ for 5 hours. After the reaction is over, centrifuge at 5000 rpm for 5 min. , Washed with water and ethanol three times each to obtain α-CoS hollow polyhedrons with a shell thickness of 20 nm.

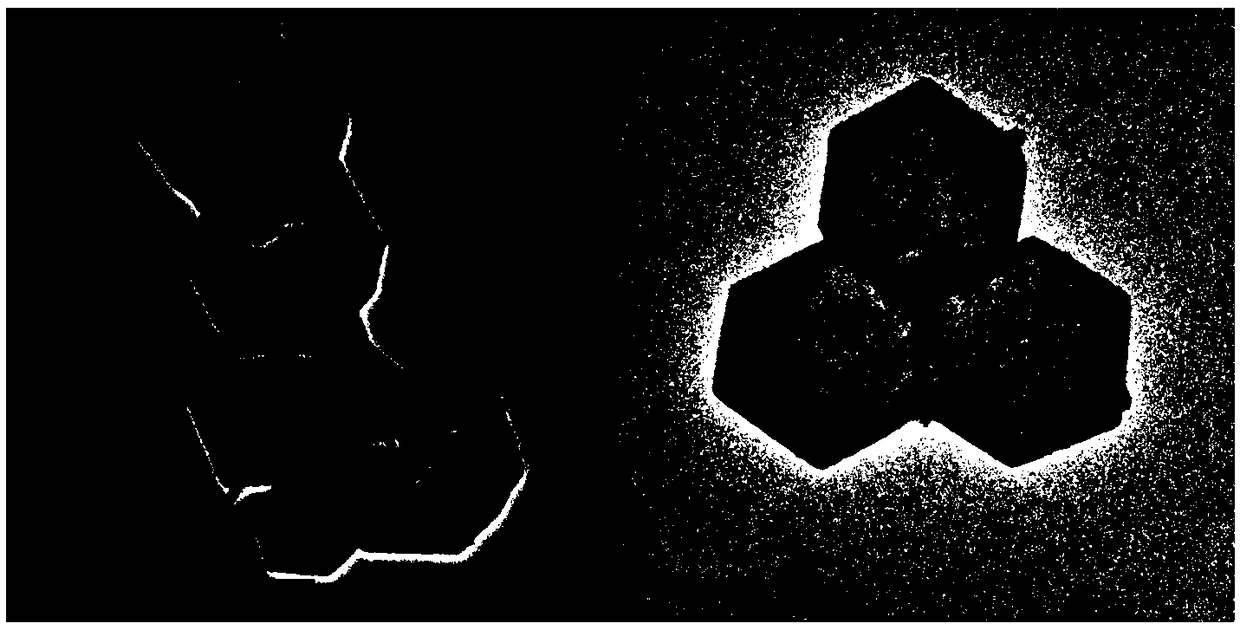

[0038] 2. Preparation of the fleece shell hollow polyhedron Co 9 S 8 @MoS 2

[0039] Disperse 30 mg of α-CoS hollow polyhedron with a wall thickness of 20 nm in 25 ml of water, add 150 mg of sodium moly...

Embodiment 3

[0042] 1. Preparation of α-CoS hollow polyhedron

[0043] Co(NO 3 ) 2 ·6H 2 291 mg of O and 1312 mg of 2-methylimidazole were dissolved in 25 ml methanol solution and mixed, stirred at room temperature for 24 hours, after the reaction, centrifuged at 6000 rpm for 5 min, washed with ethanol 4 times, and obtained the solid phase at 60℃ Dry for 6 hours to form a ZIF-67 nano-polyhedron.

[0044] Take 30 mg of ZIF-67 nano polyhedron and disperse it in 30 ml ethanol solution ultrasonically, add 300 mg of thioacetamide and transfer to a 50 ml high temperature and high pressure reactor, and react at 200 ℃ for 10 min. After the reaction is over, centrifuge at 5000 rpm for 5 min. Washed with water and ethanol three times each to obtain α-CoS hollow polyhedrons with a shell thickness of 15 nm.

[0045] 2. Preparation of the fleece shell hollow polyhedron Co 9 S 8 @MoS 2

[0046] Disperse 30 mg of the obtained α-CoS hollow polyhedron with a wall thickness of 15 nm in 50 ml of water, add 300 mg o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap