Production apparatus for carbon fiber battery module

A battery module and production device technology, which is applied in the field of carbon fiber battery module production devices, can solve problems such as failure of battery modules to work normally, manual operation errors, and reduced processing efficiency, so as to reduce manual operation intervention, avoid mistakes, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

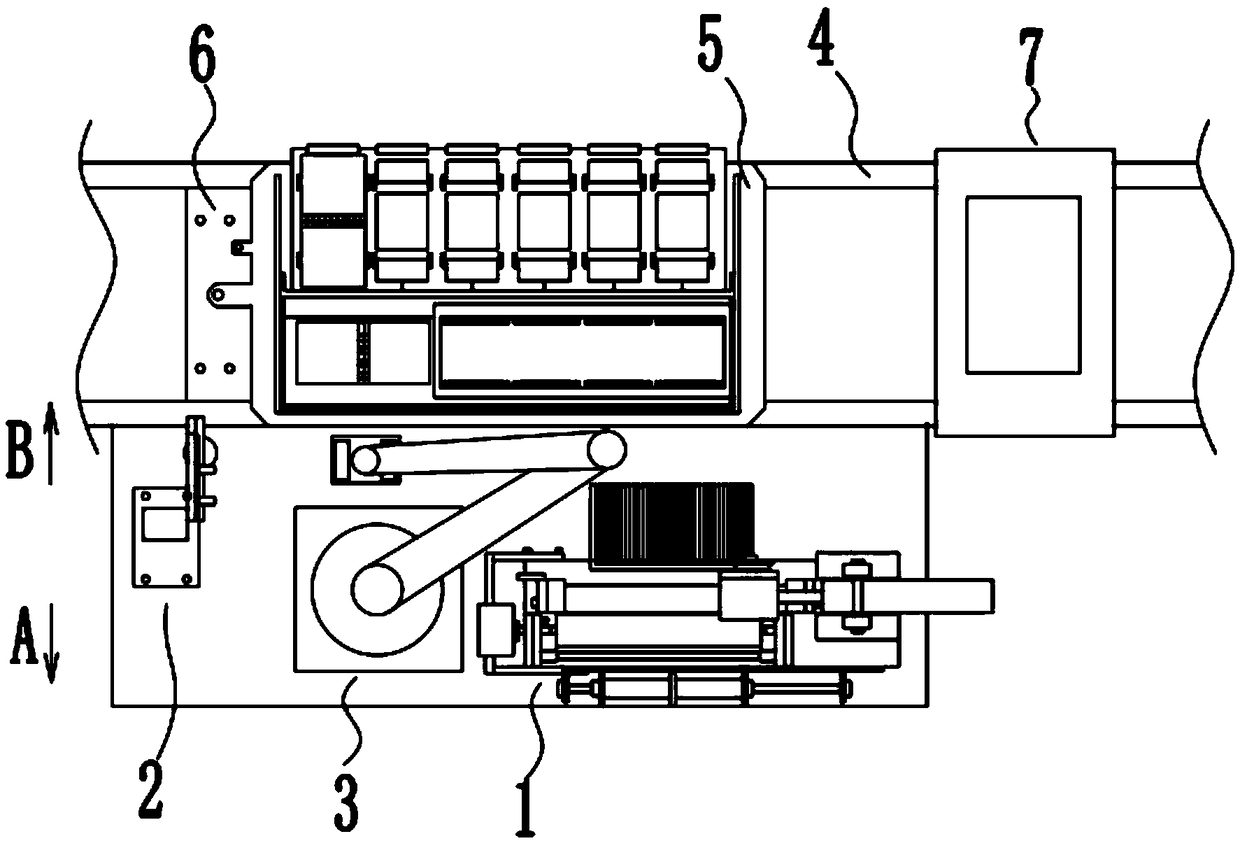

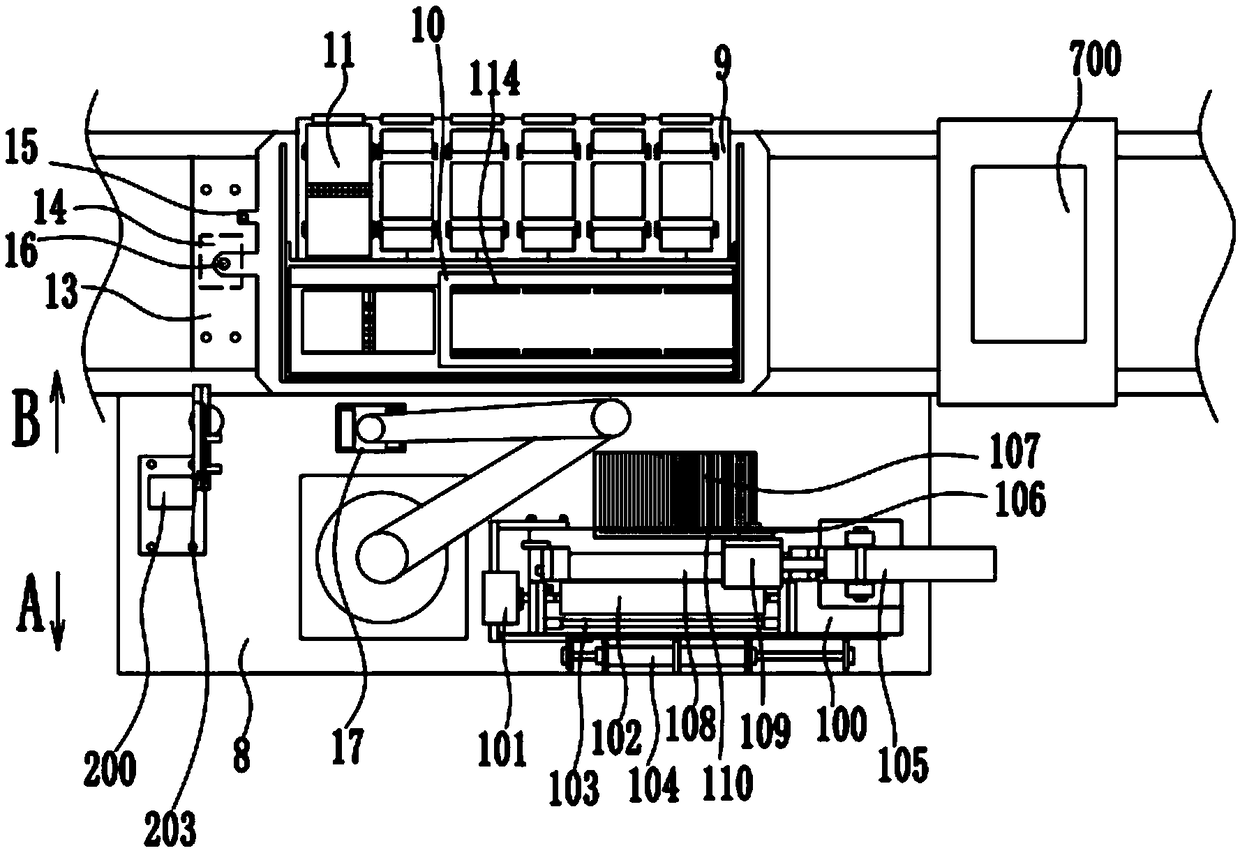

[0033] The embodiment is basically as attached figure 2 Shown: In the production device for carbon fiber battery modules in this embodiment, direction A indicates the front, and direction B indicates the rear. The carbon fiber battery module production device includes a diaphragm cutting mechanism 1, a grid cutting mechanism 2, a mechanical arm 3, an assembly frame 5, a guide rail 4, and an extrusion mechanism 7, which are installed on the same workbench 8 and have operating spaces in the same direction. Wherein, the assembly frame 5 slides from left to right along the slide rail, and a positioning mechanism 6 for positioning the assembly frame 5 is installed on the left end of the slide rail.

[0034] Diaphragm cutting mechanism 1, grid cutting mechanism 2 and mechanical arm 3 are all installed on the workbench 8 in front of guide rail 4, and diaphragm cutting mechanism 1, grid cutting mechanism 2 and guide rail 4 and assembly frame 5 on guide rail 4, among them There is a ...

Embodiment 2

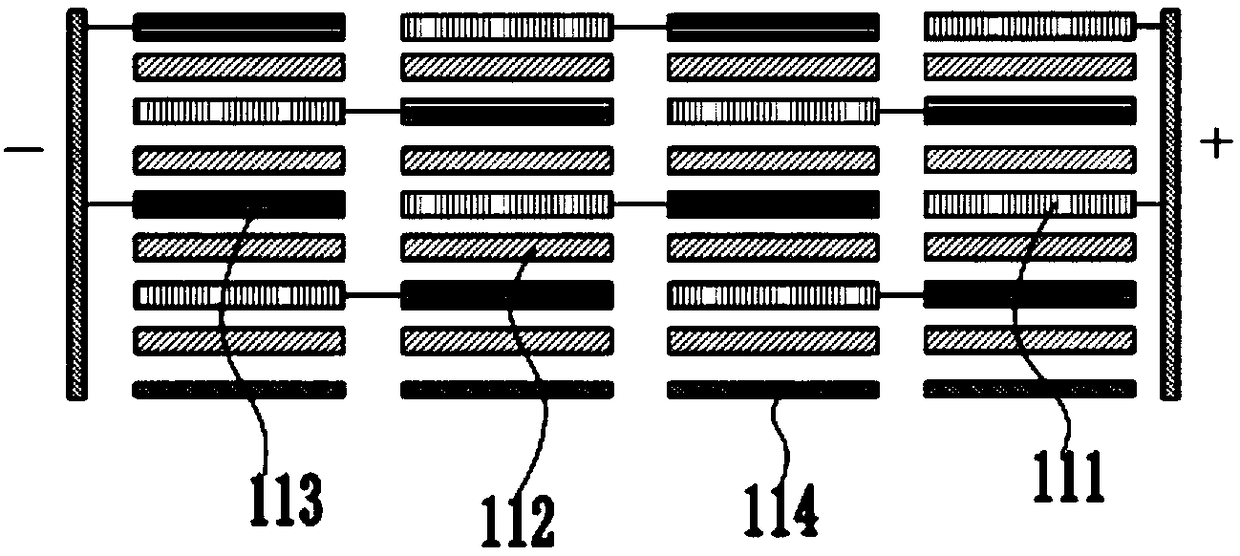

[0074] The difference between this embodiment and Embodiment 1 is that the gripper 17 in the mechanical arm 3 is a four-claw gripper 17 and the four-claw gripper 17 is provided with four sets of suction cups equipped with solenoid valves. The four-claw gripper 17 can absorb two bipolar plates 11 or two AGM diaphragms at the same time, and is used to assemble large-capacity carbon fiber batteries. Simultaneously assembling two bipolar plates 11 and diaphragms 112 greatly improves the assembly speed and reduces the assembly cost. The assembly time of the high-capacity carbon fiber battery improves the assembly efficiency. Correspondingly, the tray 9 is provided with two rows and multiple columns for placing the first installation position of the bipolar plate 11 and one second installation position for placing the casing 10 . The tray 9 is used in conjunction with the four-claw gripper 17 . The tray 9 has a large area and can accommodate more bipolar plates 11 , thereby increasi...

Embodiment 3

[0076] The difference between this embodiment and Embodiment 1 is that a control device is provided in the battery module production device, and the control device can be a microcontroller or a central processing unit. Whether there is a first detector for a single-piece diaphragm 112 on the grid cutting mechanism 2, and a second detector for detecting whether the bipolar plate 11 is put into the knife edge is installed on the support column 200 between the knife seat 203 and the cutting blade 202 in the grid cutting mechanism 2. Detector, the 3rd detector that is used to detect whether to move to designated position is installed on the gripper 17 of mechanical arm 3, and first detector, second detector and the 3rd detector are all electrically connected with control device, and control device It is also electrically connected with actuators such as the grid telescopic structure 201, the motor 101, the lateral telescopic structure 105, and the extrusion telescopic structure 700...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com