A double-layer permanent magnet composite magnetic circuit memory motor

A technology of memory motor and permanent magnet, which is applied in the direction of magnetic circuit, synchronous motor with stationary armature and rotating magnet, magnetic circuit rotating parts, etc. It can solve the problems of cross demagnetization and low coercivity permanent magnet, etc. Achieve stable working point, increase torque density, and easy to achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment, should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art can modify various equivalent forms of the present invention All fall within the scope defined by the appended claims of this application.

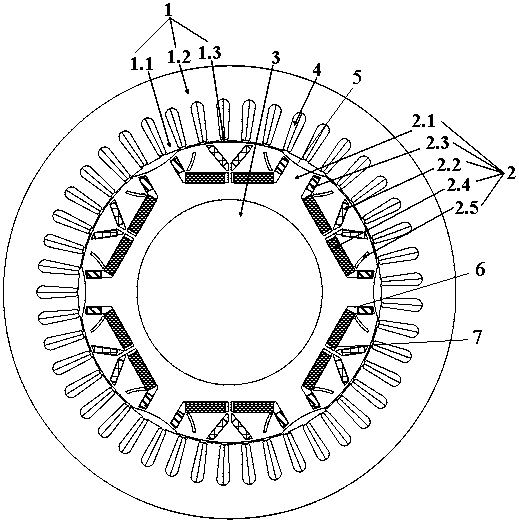

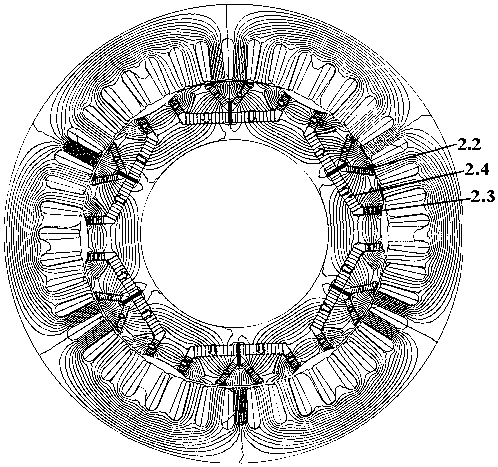

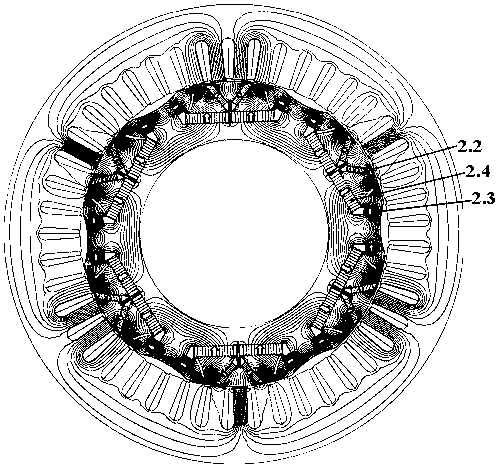

[0025] Please combine Figure 1 to Figure 3 As shown, the double-layer permanent magnet composite magnetic circuit memory motor involved in this embodiment includes a stator 1 , an armature winding 4 , a hybrid permanent magnet rotor 2 and a non-magnetically conductive rotating shaft 3 . The stator is arranged outside the hybrid permanent magnet rotor, and the stator includes stator core teeth 1.1, stator yoke 1.2 and armature winding 4 arranged on the stator core teeth, and the stator core teeth 1.1 are arranged between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com