A stirrer for waterproof coating

A stirring device and waterproof coating technology, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve the problems of low stirring efficiency and uneven stirring, and achieve high stirring efficiency, enhanced applicability, Applicable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

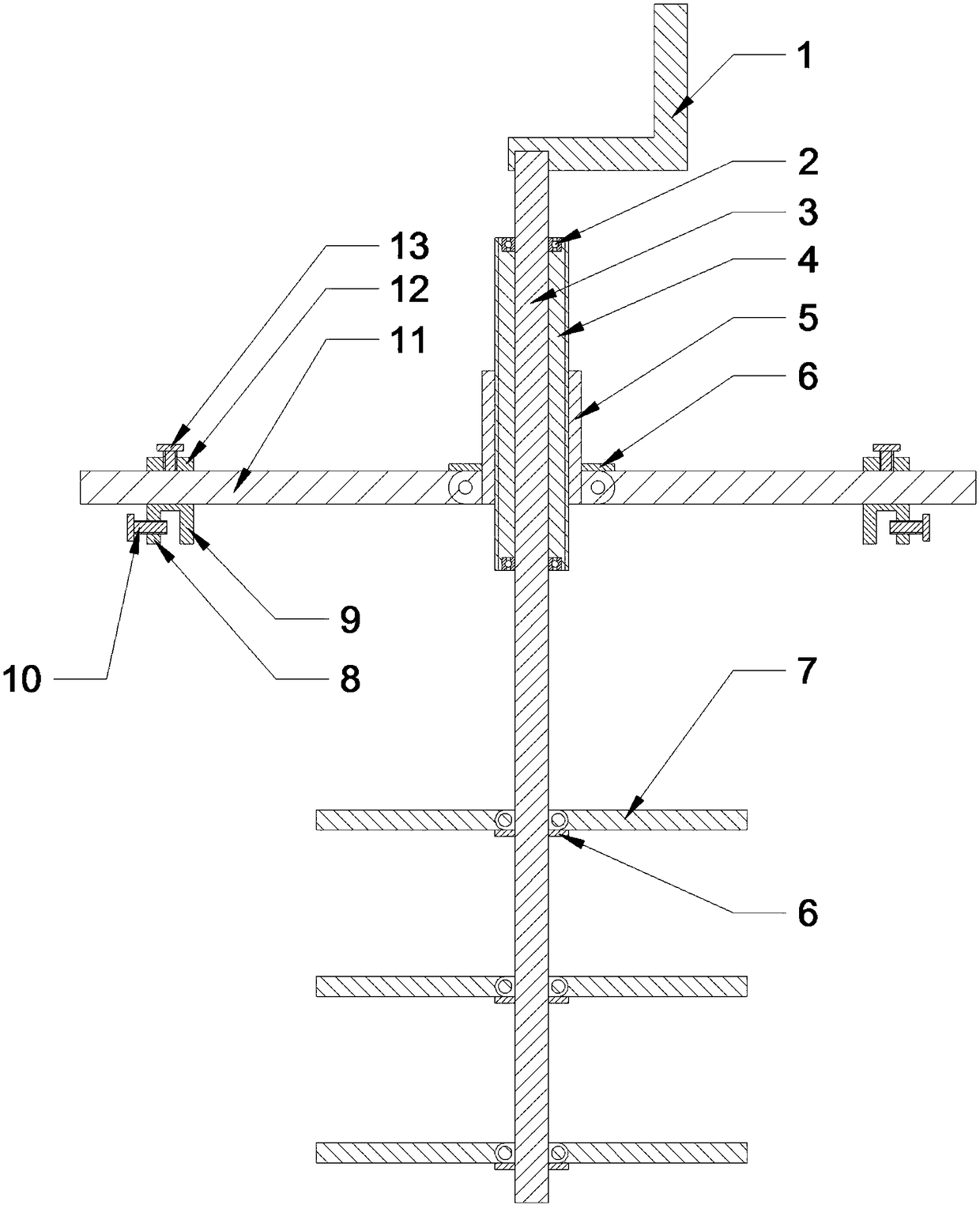

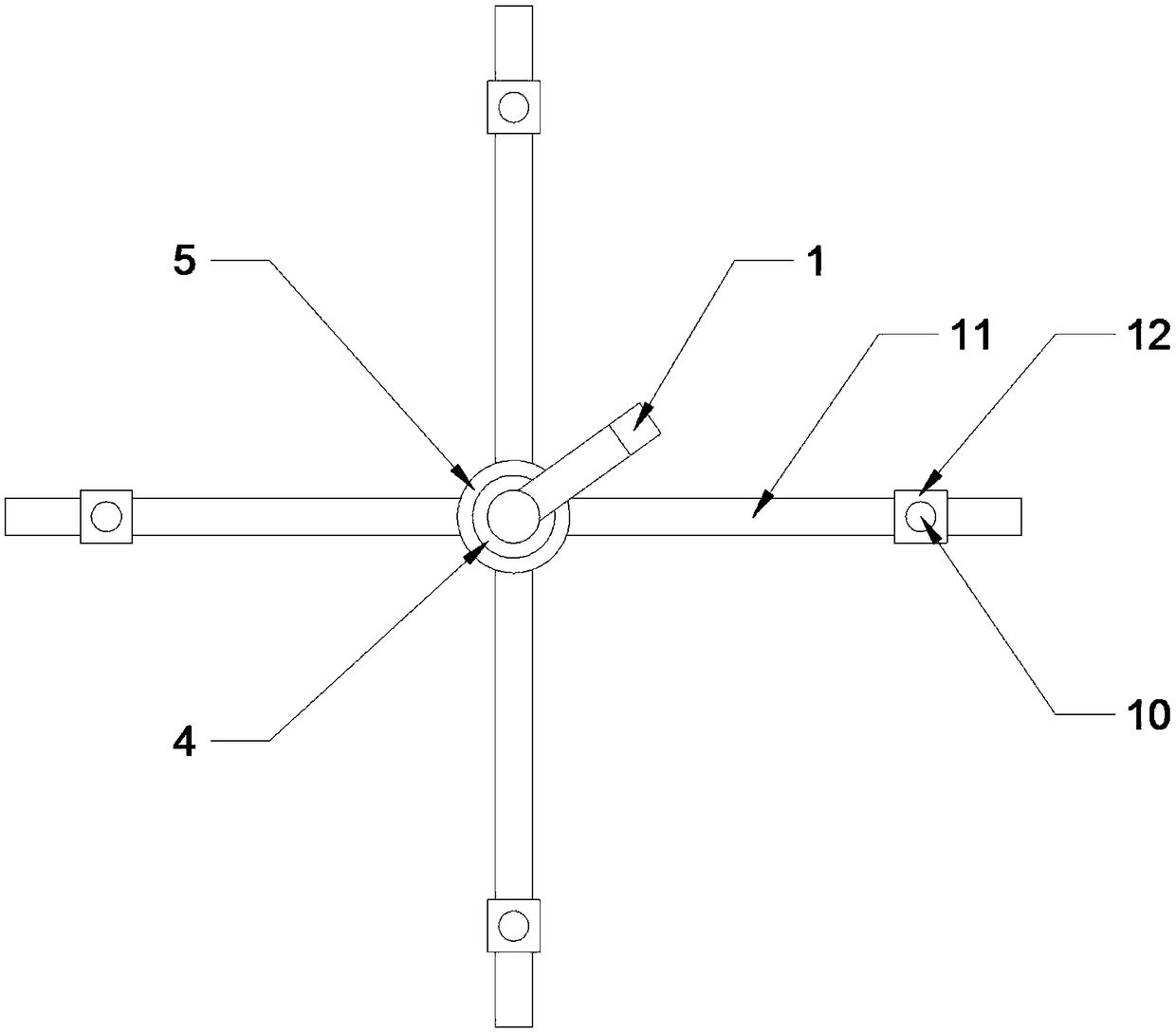

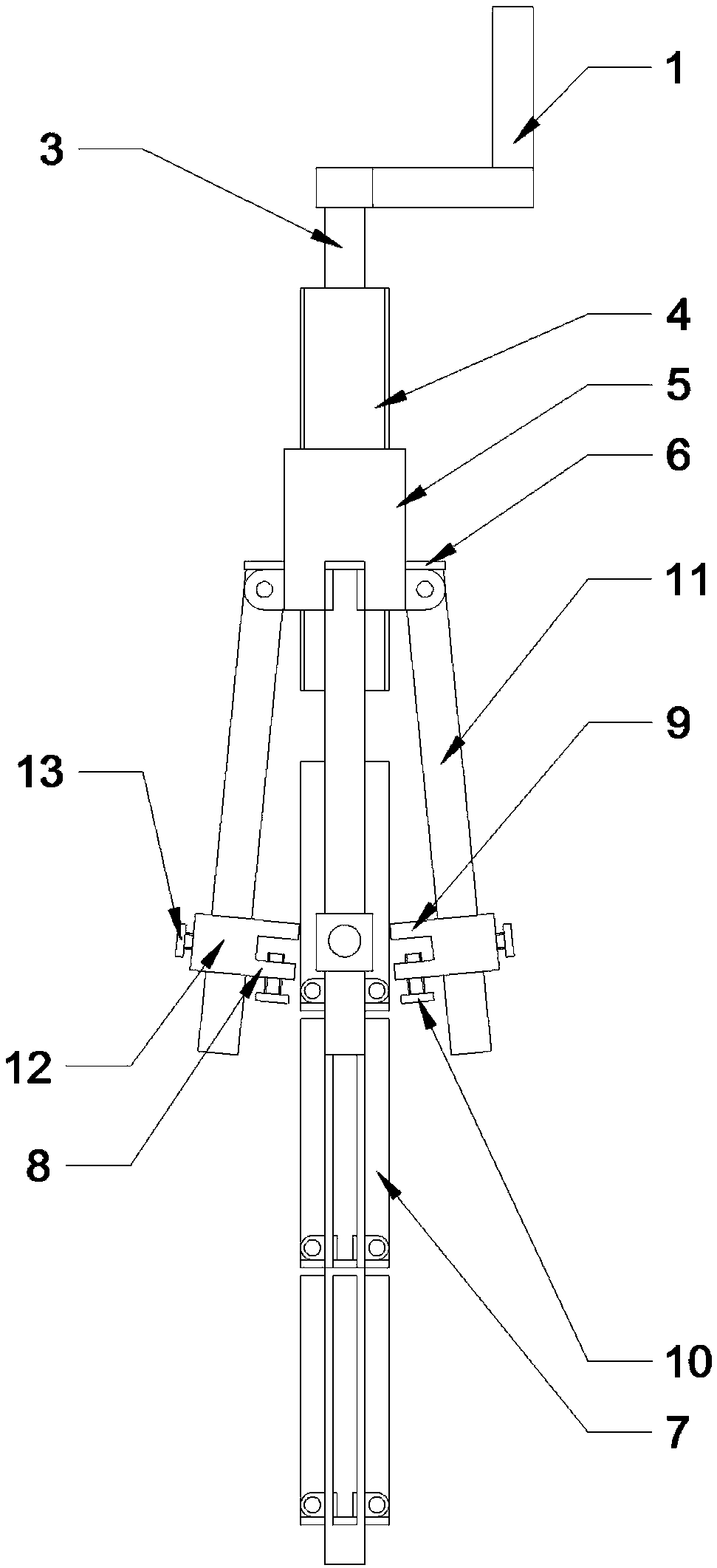

[0029] see Figure 1~4 , a waterproof paint mixing device, comprising a stirring shaft 3, a plurality of stirring rods 7 are arranged at the lower end of the stirring shaft 3, and the upper end of the stirring shaft 3 is set in the through hole of the inner sleeve 4 and can only rotate freely; the outer surface of the inner sleeve 4 An external thread is provided, and the inner sleeve 4 is set in the through hole of the outer sleeve 5, and the inner surface of the through hole of the outer sleeve 5 is provided with an internal thread that cooperates with the outer thread of the inner sleeve 4; the outer surface of the outer sleeve 5 is provided with a The cross bar 11 perpendicular to the stirring shaft 3, the cross bar 11 is covered with a clamping mechanism, which can be clamped and fixed with the paint bucket 13, and the number of the cross bar 11 is at least 2 and is evenly distributed radially along the outer sleeve 5 .

[0030] In this example, first dry powder and solv...

Embodiment 2

[0032] see Figure 1~4 , a waterproof paint mixing device, comprising a stirring shaft 3, a plurality of stirring rods 7 are arranged at the lower end of the stirring shaft 3, and the upper end of the stirring shaft 3 is set in the through hole of the inner sleeve 4 and can only rotate freely; the outer surface of the inner sleeve 4 An external thread is provided, and the inner sleeve 4 is set in the through hole of the outer sleeve 5, and the inner surface of the through hole of the outer sleeve 5 is provided with an internal thread that cooperates with the outer thread of the inner sleeve 4; the outer surface of the outer sleeve 5 is provided with a The cross bar 11 perpendicular to the stirring shaft 3, the cross bar 11 is covered with a clamping mechanism, which can be clamped and fixed with the paint bucket 13, and the number of the cross bar 11 is at least 2 and is evenly distributed radially along the outer sleeve 5 .

[0033] In this example, the stirring rod 7 is hin...

Embodiment 3

[0036] see Figure 1~4 , a waterproof paint mixing device, comprising a stirring shaft 3, a plurality of stirring rods 7 are arranged at the lower end of the stirring shaft 3, and the upper end of the stirring shaft 3 is set in the through hole of the inner sleeve 4 and can only rotate freely; the outer surface of the inner sleeve 4 An external thread is provided, and the inner sleeve 4 is set in the through hole of the outer sleeve 5, and the inner surface of the through hole of the outer sleeve 5 is provided with an internal thread that cooperates with the outer thread of the inner sleeve 4; the outer surface of the outer sleeve 5 is provided with a The cross bar 11 perpendicular to the stirring shaft 3, the cross bar 11 is covered with a clamping mechanism, which can be clamped and fixed with the paint bucket 13, and the number of the cross bar 11 is at least 2 and is evenly distributed radially along the outer sleeve 5 .

[0037] In this example, the clamping mechanism in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com