Energy-saving and environment-friendly civil engineering construction waste treatment device

A technology for civil engineering and construction waste, which is applied in the field of civil engineering and construction waste treatment devices, can solve problems such as non-continuous operation, low work efficiency, and non-environmental protection, and achieve the effects of improving efficiency, reducing manpower input, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

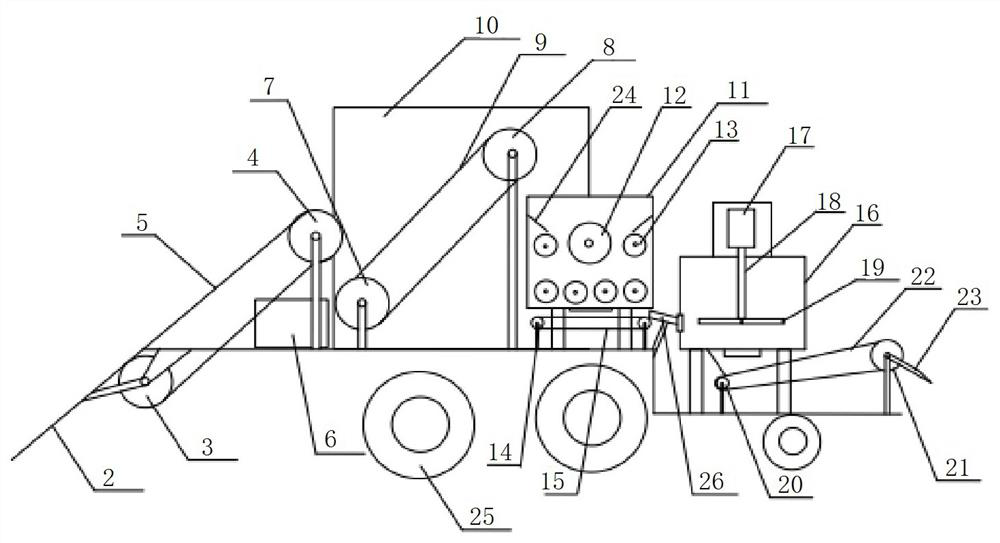

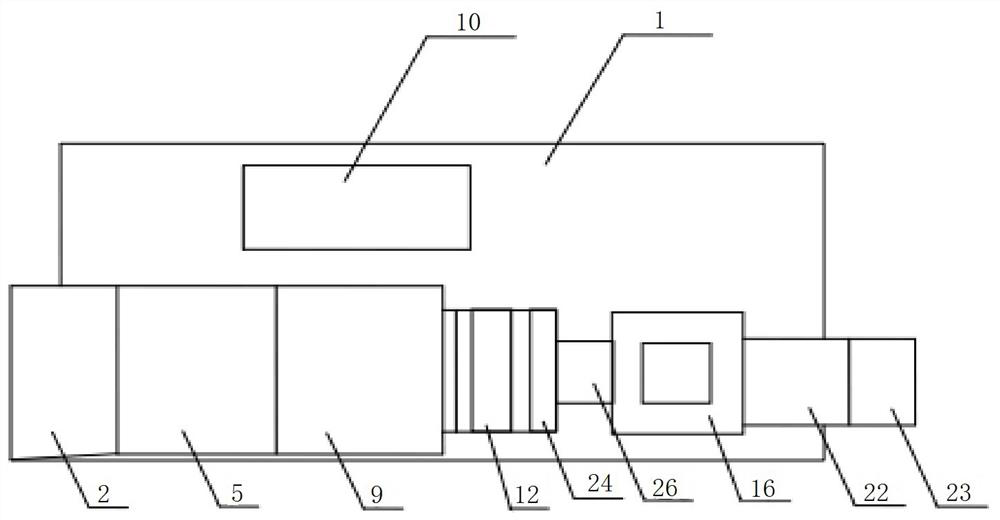

[0030] Embodiment 1: An energy-saving and environment-friendly civil engineering construction waste treatment device, see figure 1 and figure 2 , which includes a separation module, a crushing module and a crushing module; the separation module includes a shovel plate 2, a first belt 5 and a second belt 9; the first belt 5 is provided with a first driving wheel 3 and a first driven wheel 4, and the shovel plate 2 Fixedly connected with the first driving wheel 3, the first driven wheel 3 is provided with an electromagnet; the output end of the first belt 5 is connected with the input end of the second belt 9; the second belt 9 is provided with the second driving wheel 7 and the second belt 9 Two driven wheels 8; the crushing module includes a crushing box 11 and a transmission pipeline 26; the output end of the second belt 9 is connected to the crushing box 11, and the bottom of the crushing box 11 is provided with a first discharge port; the bottom of the first discharge port...

Embodiment 2

[0031] Embodiment 2: An energy-saving and environment-friendly civil engineering construction waste treatment device, see figure 1 and figure 2 , is basically the same as Embodiment 1, the difference is that: the separation module also includes a receiving box 6; the receiving box 6 is arranged under the side of the first driven wheel 4; the second driving wheel 7 is fixedly connected with two first Baffle plate; the first crushing roller 12 and the second crushing roller 13 are arranged in the crushing box 11 of the crushing module, and the second crushing roller 13 is divided into an upper crushing roller and a lower crushing roller according to different installation positions; the crushing box of the crushing module 16 is provided with a rotating rod 18 and a crushing knife 19, the rotating rod 18 is driven by the seventh motor 17, and the lower end of the rotating rod 18 is fixedly connected with the crushing knife 19.

Embodiment 3

[0032] Embodiment 3: An energy-saving and environment-friendly civil engineering construction waste treatment device, see figure 1 and figure 2 , substantially the same as Embodiment 2, except that the device includes a separation module, a crushing module, a crushing module and a support plate 1, the crushing module also includes a blower, and the blower is arranged under the fourth driven wheel 21, and the blower The air outlet is facing the lower end of the chute 23; the first driving wheel 3, the first driven wheel 4, the second driving wheel 7, the second driven wheel 8, the crushing box 11, the third driving wheel 14, the third driven wheel, Crushing box 16, the 4th driving wheel 20 and the 4th passive 21 wheels are all fixed on the support plate 1, and the support plate 1 is also provided with driver's cab 10, and many groups of wheels 25 are installed at the support plate 1 bottom.

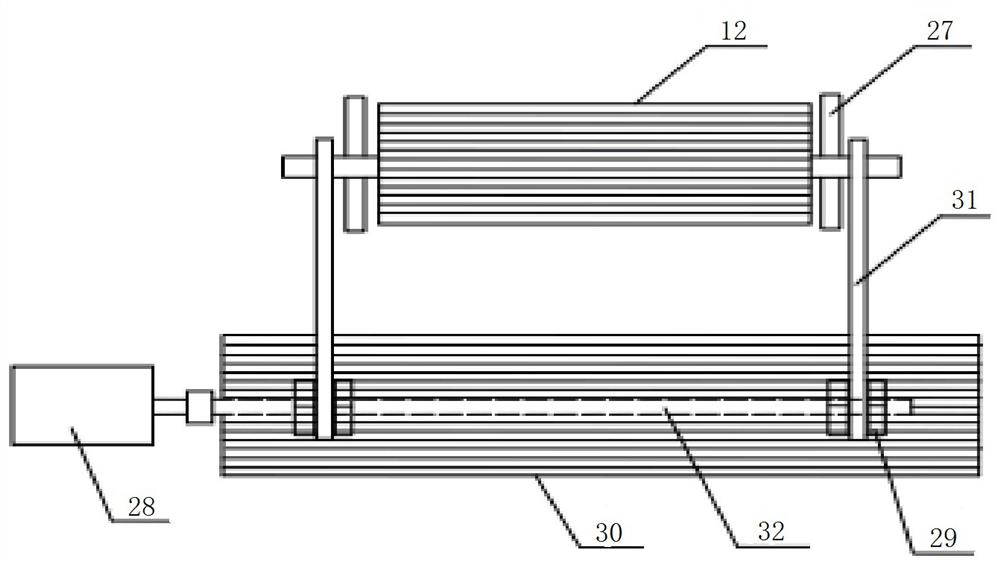

[0033] see image 3 , the first crushing roller 12 in the crushing box 11 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com