Automatic conveying device for metal wires

A conveying device and metal wire technology, which is applied in the field of automation, can solve problems such as low work efficiency and unevenness, and achieve the effects of improving work efficiency, ensuring cleanliness, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

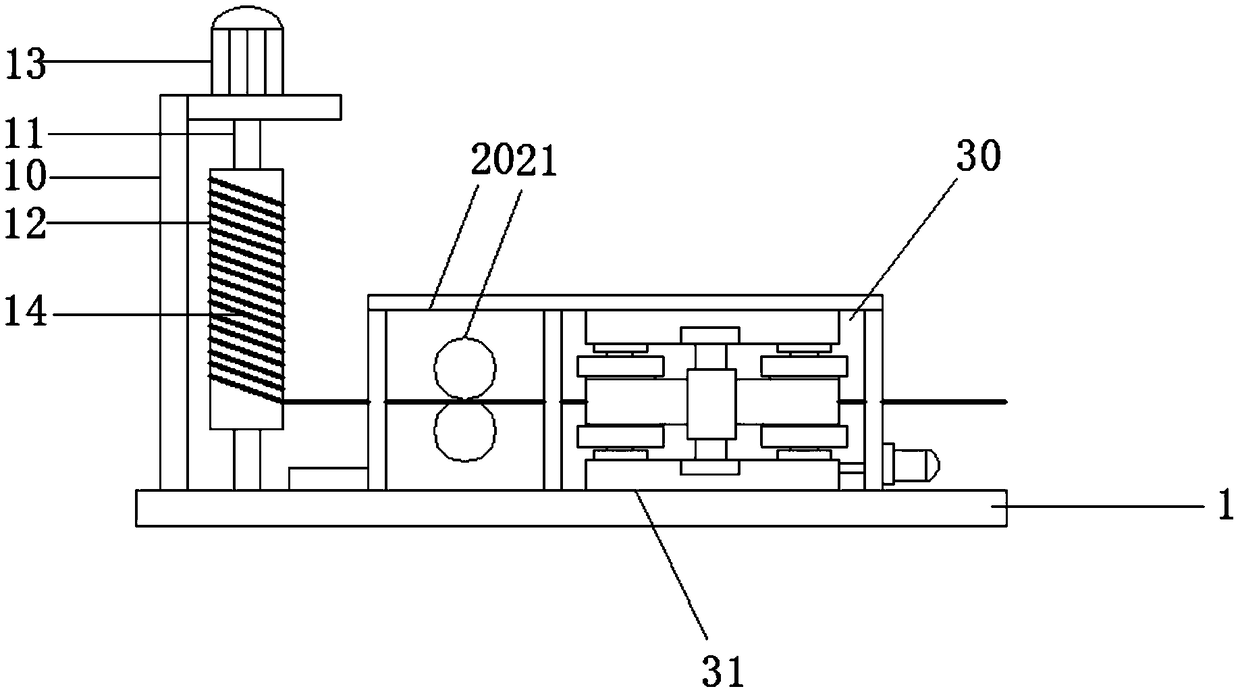

[0023] An automatic conveying device for metal wire, please refer to figure 1 , Including a conveying seat 1, on which a conveying stand 10, a glue removal cavity 20 and a guide cavity 30 are installed, and a threading is provided between the conveying rack 10, the glue removal cavity 20 and the guide cavity 30 The conveying rack 10 is located at the front end of the conveying base 1, a conveying shaft 11 is vertically installed on the conveying rack 10, and a winding roller 12 is installed on the conveying shaft 11. A feeding motor 13 is installed at the top of the frame 10, and the feeding rotating shaft 11 is connected with the motor shaft of the feeding motor 13. The wire is wound on the winding roller 12, and the conveying motor 13 serves as a driving device for the conveying operation.

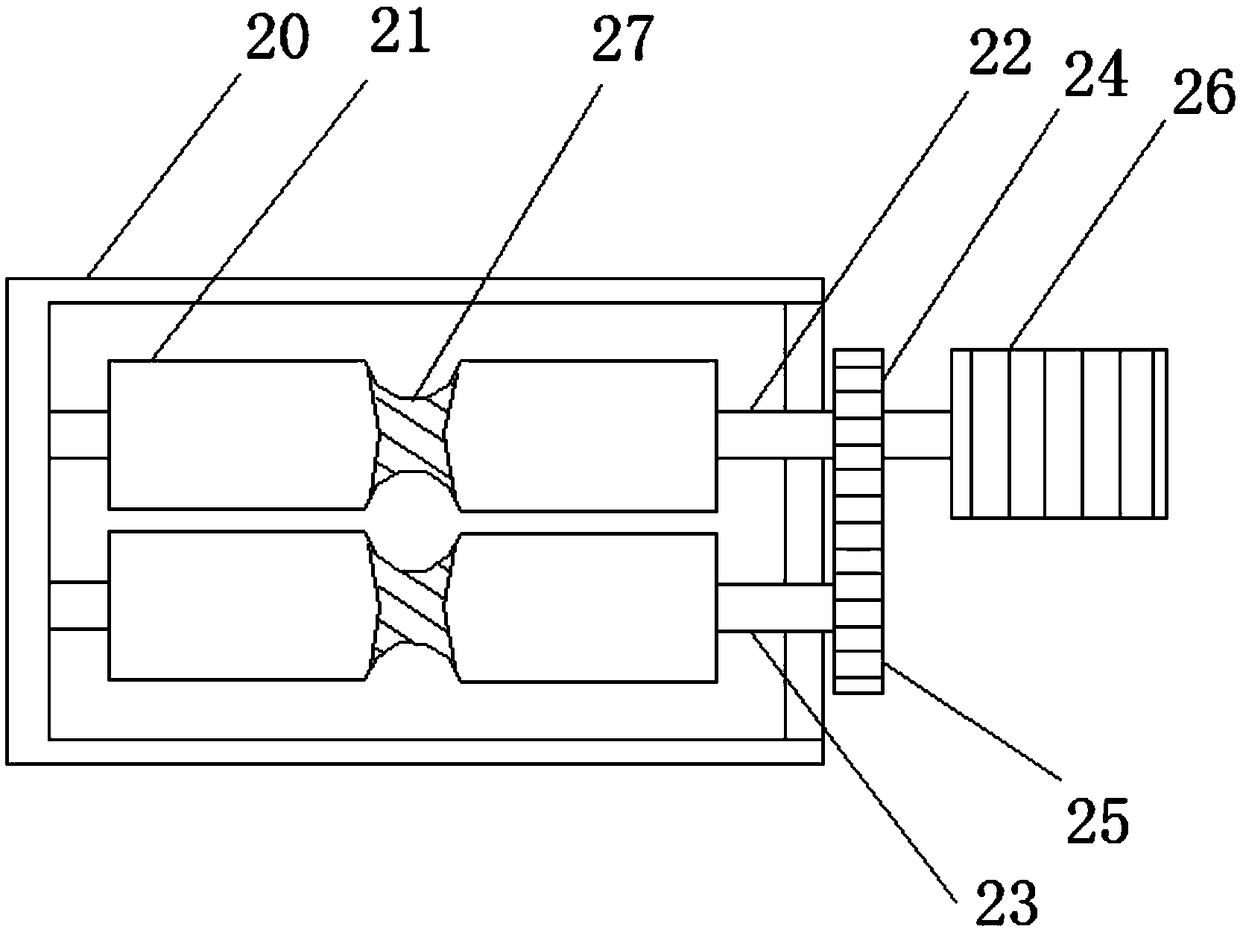

[0024] See figure 2 , The glue removal cavity 20 is located behind the conveying rack 10, and a glue removal roller 21 is installed in the glue removal cavity 20, and the glue removal roll...

Embodiment 2

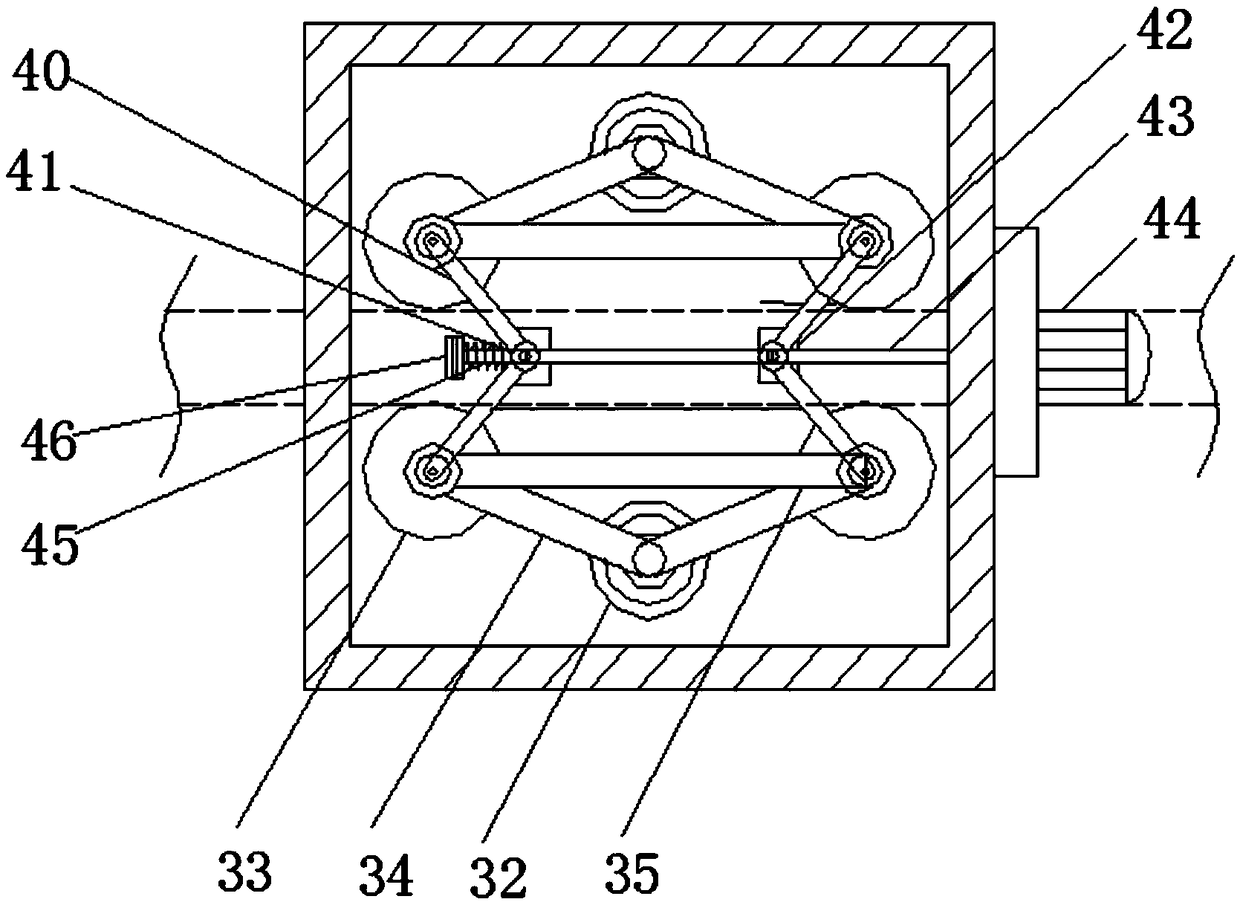

[0030] As a further optimization of the foregoing embodiment, on the basis of the first embodiment, the movable roller 33 includes an inner rod 51, an inner skin layer 52 and an outer skin layer 53, the inner rod 51 is mounted on the transmission frame 31, and the inner rod The skin layer 52 wraps the outer side of the inner rod 51, the outer skin layer 53 wraps the outer side of the inner skin layer 52, the inner skin layer 52 is installed with a compression spring 55, and the compression spring 55 supports the entire inner skin layer 52, so Several burrs 54 are installed on the outer side of the outer skin layer 53 at equal angles.

[0031] During operation, while the compression spring 55 supports the entire inner skin layer 52, it also acts as a buffer against the force of the outer skin layer 53 to avoid damage to the metal wire during limiting extrusion; the outer skin layer 53 is installed with several burrs 54, When in contact with the metal wire, clean the remaining powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com