A 3D printing method

A 3D printing and printing powder technology, which is applied in the field of 3D printing, can solve the problems of particles, rough outer surface, poor hand feeling, etc., and achieve the effect of improving experience and not rough outer surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

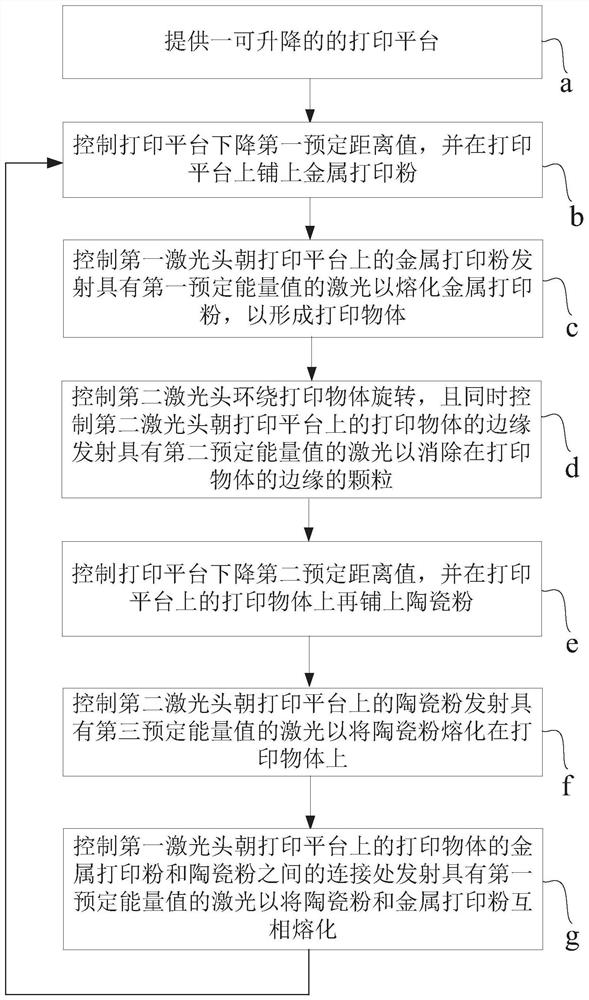

[0018] Such as figure 1 as shown, figure 1 It is a schematic flow chart of the 3D printing method of the present invention. The 3D printing method comprises the following steps:

[0019] Step a: providing a liftable printing platform.

[0020] Step b: controlling the printing platform to descend by a first predetermined distance, and spreading metal printing powder on the printing platform.

[0021] It should be understood that the first predetermined distance value is a set value, which can be set on the printer according to actual needs.

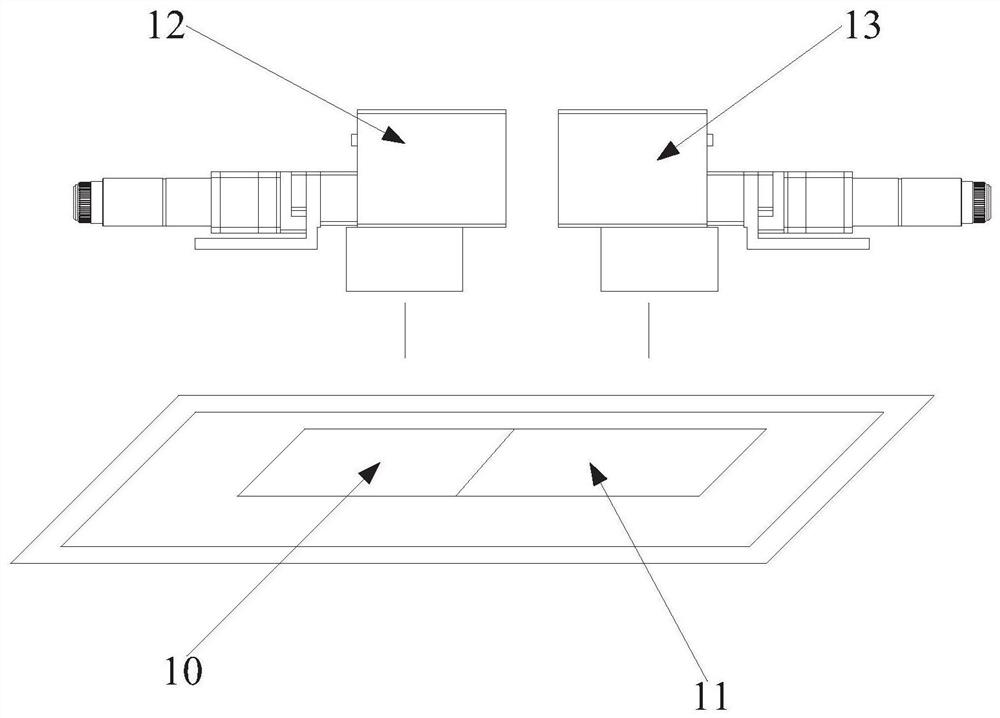

[0022] It is worth noting that if figure 2 As shown, in some embodiments, the metal printing powder includes a first metal printing powder and a second metal printing powder, and the printing platform includes a first printing area 10 and a second printing area 11 . Wherein the step b of controlling the printing platform to drop the first predetermined distance value, and laying metal printing powder on the printing platform includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com