A stirring type water washing device for precipitate blocks in a rare earth oxide production process

A rare earth oxide and production process technology, applied in the fields of rare earth metal oxides/hydroxides, rare earth metal compounds, inorganic chemistry, etc., can solve the problems of low washing efficiency, labor consumption, and insufficient washing, and reduce manpower. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

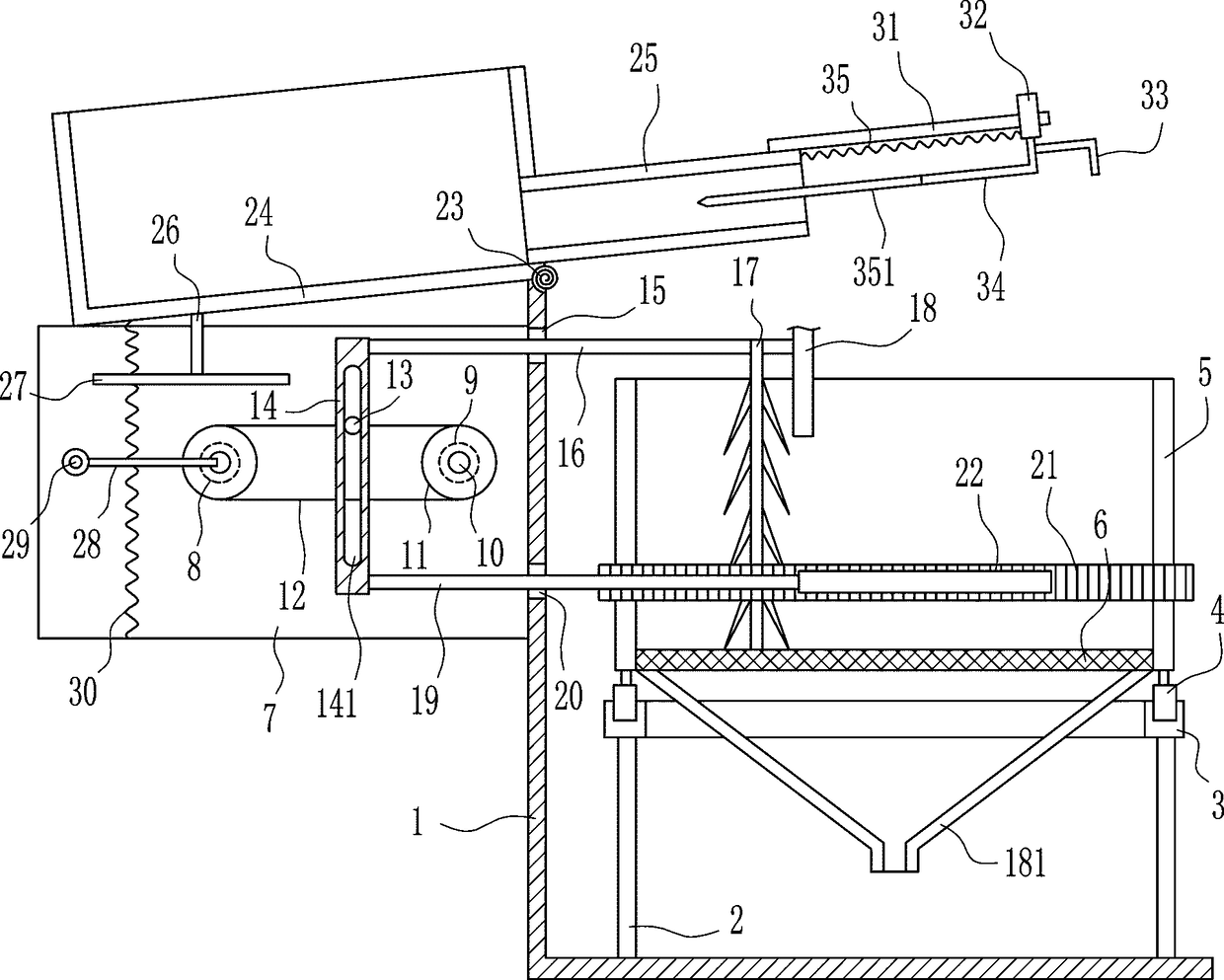

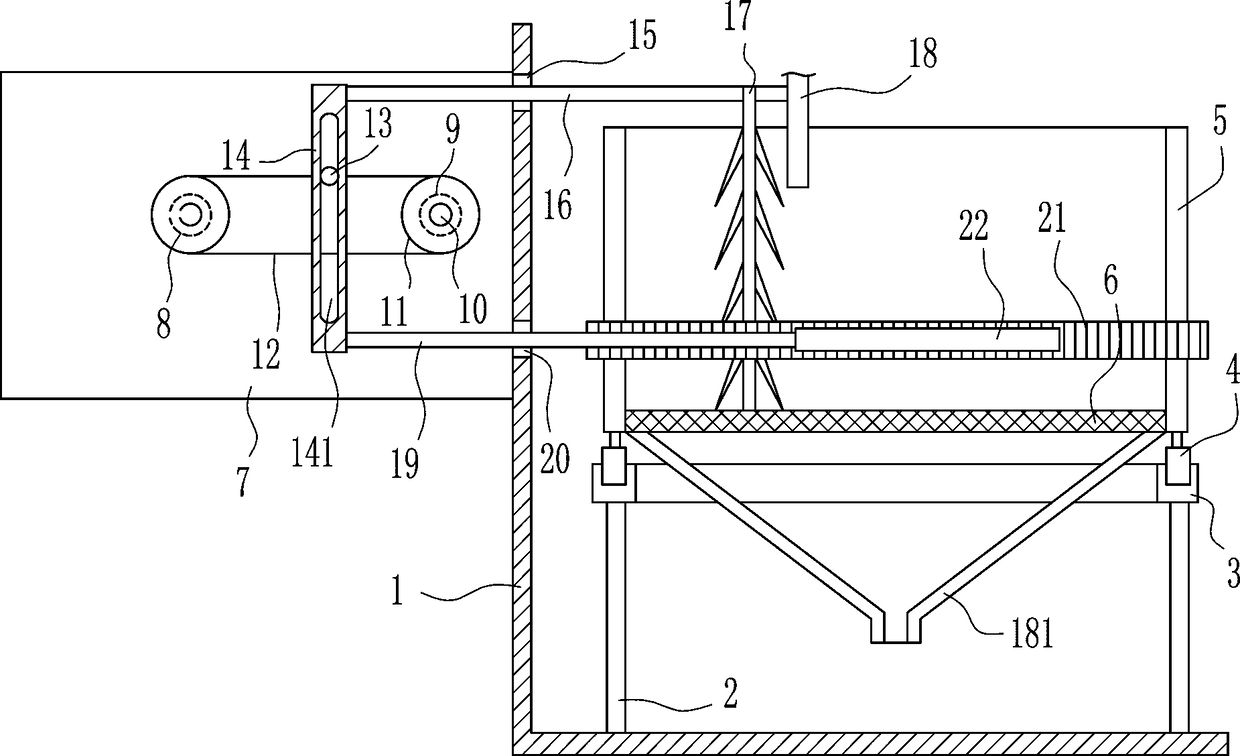

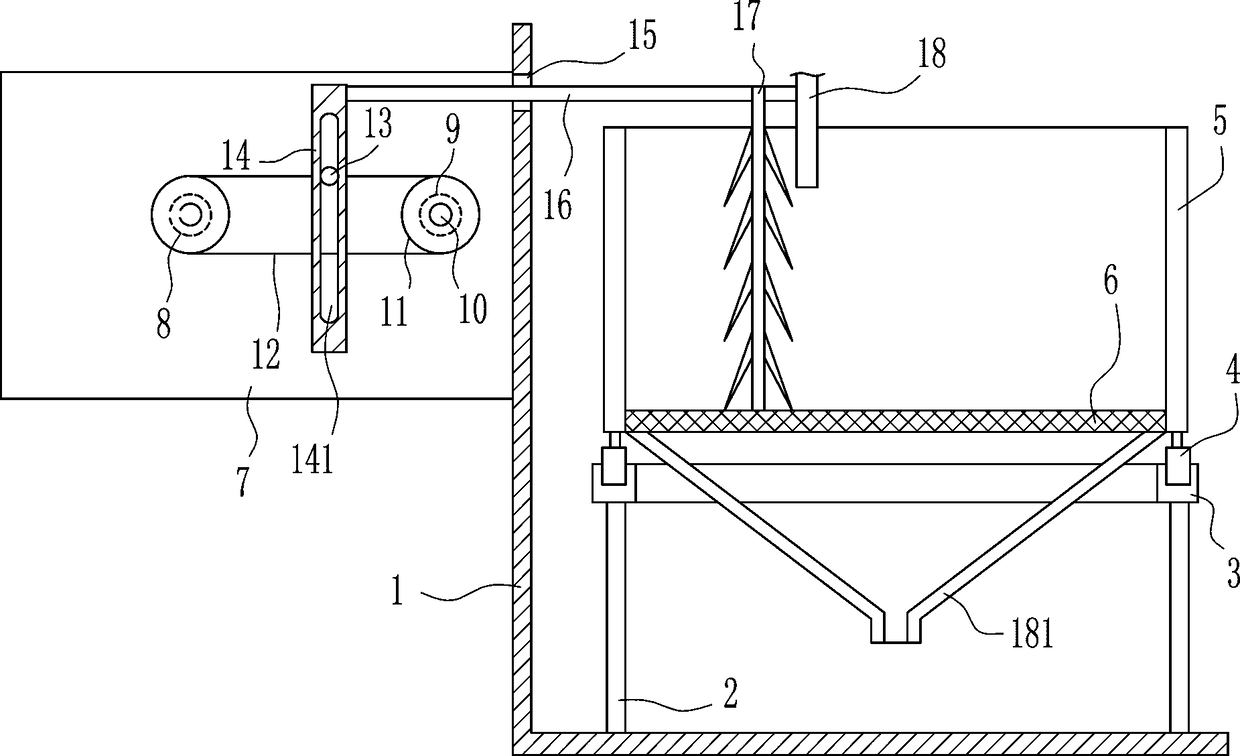

[0024] A kind of agitating water washing equipment for sedimentary block in the production process of rare earth oxide, such as Figure 1-5 As shown, it includes a mounting frame 1, a mounting rod 2, an annular slide rail 3, a first slider 4, a washing box 5, a screen 6, a fixed plate 7, a motor 8, a bearing seat 9, a rotating rod 10, and a pulley 11. , the flat belt 12, the sliding shaft 13, the first moving plate 14, the first moving rod 16, the stirring rod 17, the water pipe 18 and the drain hopper 181, the left and right parts of the bottom of the mounting frame 1 are connected with the mounting rod 2, and the left and right sides are There is an annular slide rail 3 between the top of the mounting rod 2, the left and right parts of the annular slide rail 3 are slidably connected with a first slider 4, and a washing box 5 is installed between the upper sides of the first slider 4 on the left and right sides. The bottom of the washing box 5 is provided with a sieve 6, the bo...

Embodiment 2

[0026] A kind of agitating water washing equipment for sedimentary block in the production process of rare earth oxide, such as Figure 1-5 As shown, it includes a mounting frame 1, a mounting rod 2, an annular slide rail 3, a first slider 4, a washing box 5, a screen 6, a fixed plate 7, a motor 8, a bearing seat 9, a rotating rod 10, and a pulley 11. , the flat belt 12, the sliding shaft 13, the first moving plate 14, the first moving rod 16, the stirring rod 17, the water pipe 18 and the drain hopper 181, the left and right parts of the bottom of the mounting frame 1 are connected with the mounting rod 2, and the left and right sides are There is an annular slide rail 3 between the top of the mounting rod 2, the left and right parts of the annular slide rail 3 are slidably connected with a first slider 4, and a washing box 5 is installed between the upper sides of the first slider 4 on the left and right sides. The bottom of the washing box 5 is provided with a sieve 6, the ...

Embodiment 3

[0029] A kind of agitating water washing equipment for sedimentary block in the production process of rare earth oxide, such as Figure 1-5 As shown, it includes a mounting frame 1, a mounting rod 2, an annular slide rail 3, a first slider 4, a washing box 5, a screen 6, a fixed plate 7, a motor 8, a bearing seat 9, a rotating rod 10, and a pulley 11. , the flat belt 12, the sliding shaft 13, the first moving plate 14, the first moving rod 16, the stirring rod 17, the water pipe 18 and the drain hopper 181, the left and right parts of the bottom of the mounting frame 1 are connected with the mounting rod 2, and the left and right sides are There is an annular slide rail 3 between the top of the mounting rod 2, the left and right parts of the annular slide rail 3 are slidably connected with a first slider 4, and a washing box 5 is installed between the upper sides of the first slider 4 on the left and right sides. The bottom of the washing box 5 is provided with a sieve 6, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com