Liquid gas energy water pump sewage treatment system

A technology of sewage treatment system and liquid gas energy, applied in the field of medium machinery, can solve the problems of unsuitable use and high cost in remote or mountainous areas, and achieve the effect of enhancing propulsion and speeding up purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

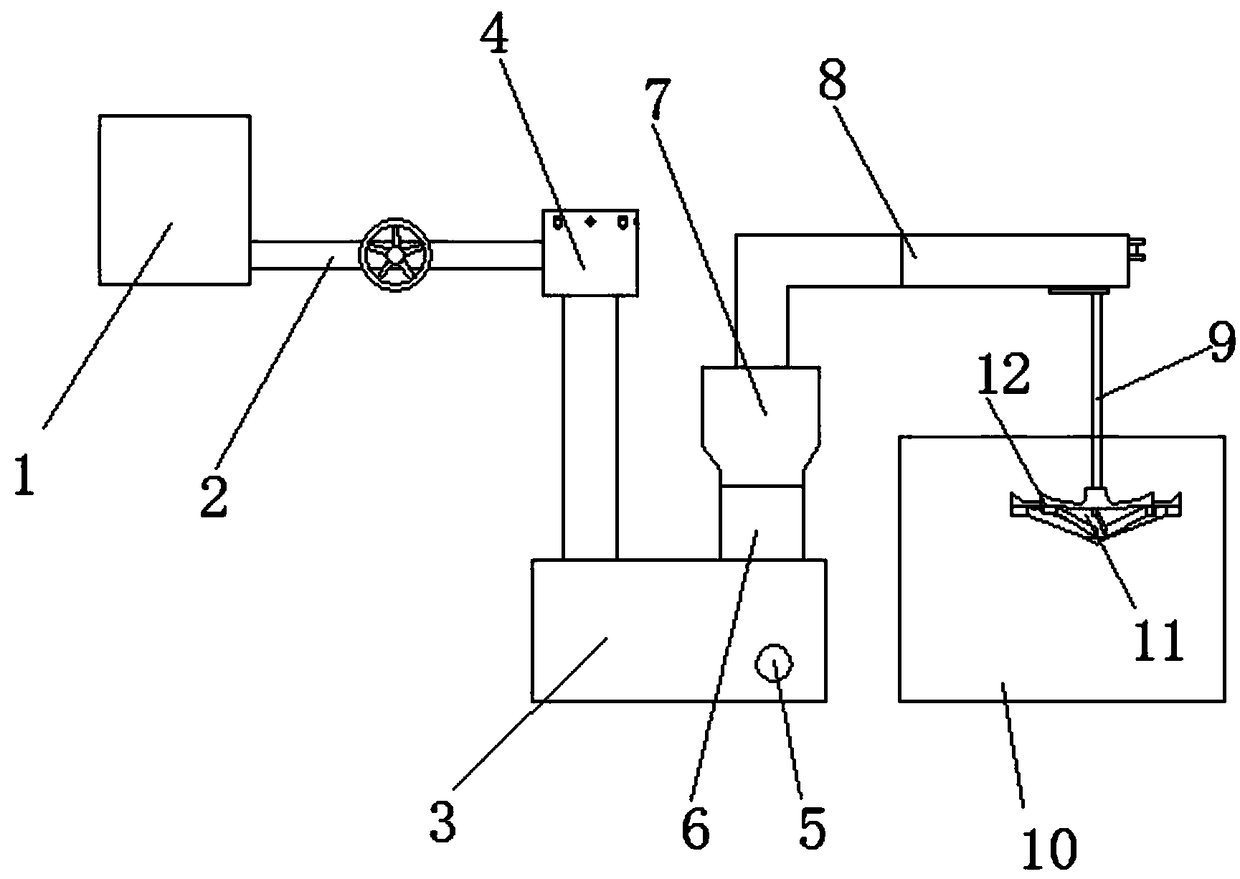

[0014] Attached below Figure 1-4 Shown is a further description of a liquid-gas energy water pump sewage treatment system of the present invention.

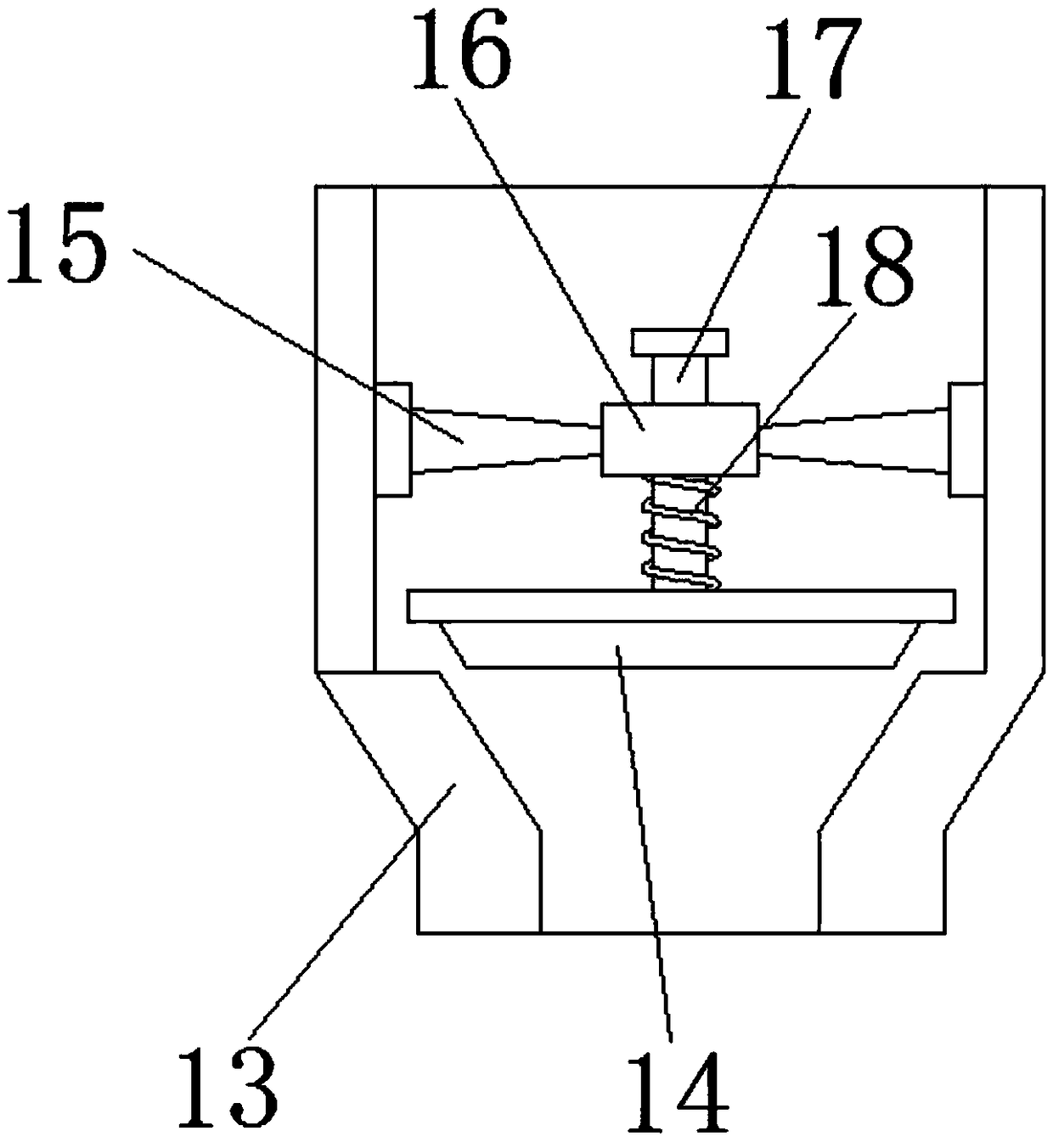

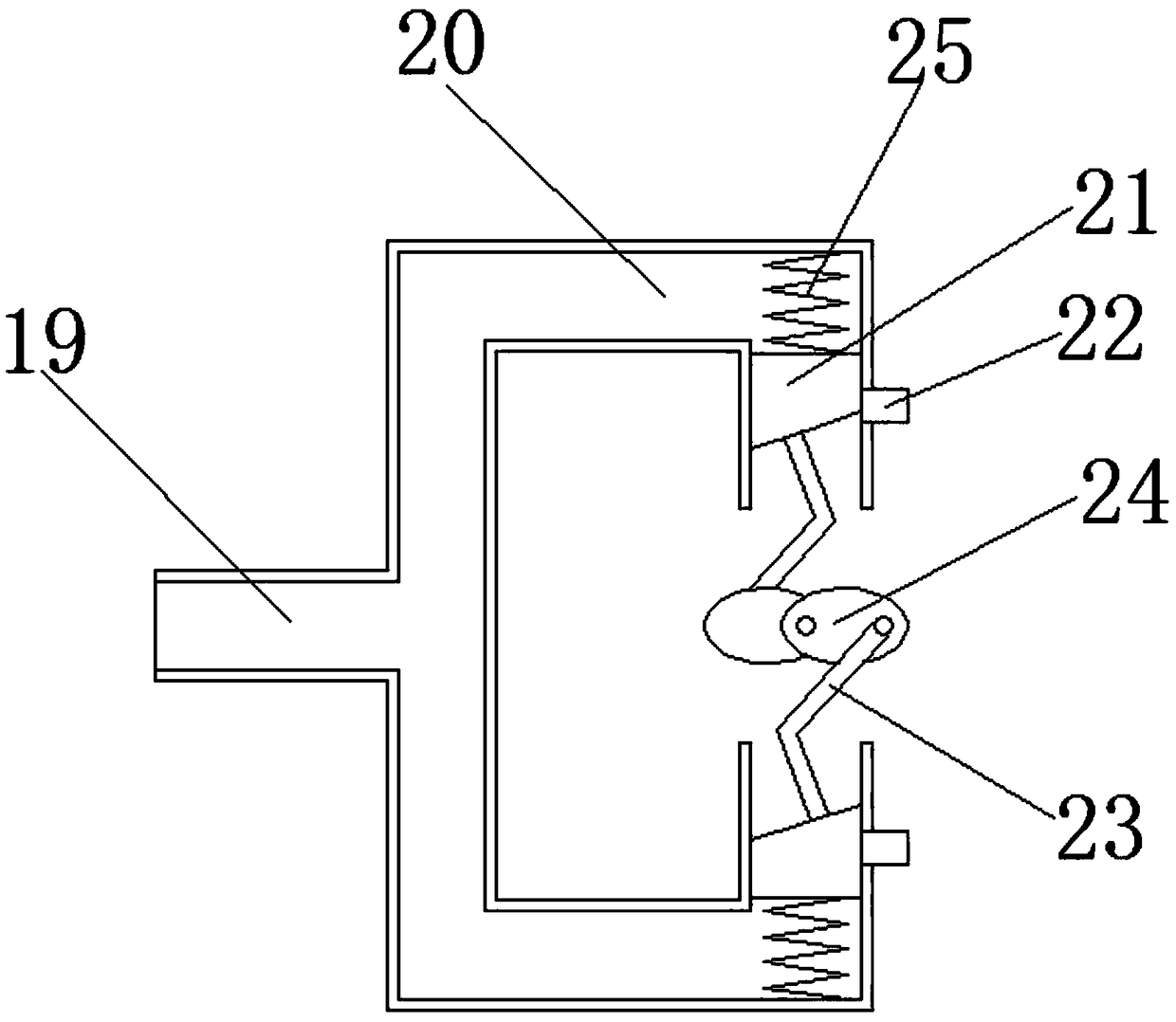

[0015] A liquid-gas energy water pump sewage treatment system, comprising a high-level water source 1, a water inlet pipe 2 connected to the right side of the high-level water source 1, a liquid-gas separation box 3 connected to the lower part of the water inlet pipe 2, and an air intake mechanism 4 arranged in the middle of the water inlet pipe 2, The front side of the liquid-gas separation box 3 is connected with a drain pipe 5, and the upper right side of the liquid-gas separation box 3 is provided with an air collection chamber 6, and the upper part of the air collection chamber 6 is connected with a pressure valve 7, and the upper part of the pressure valve 7 is connected with a driving mechanism 8. The lower part of the mechanism 8 is provided with a rotating shaft 9, and the lower part of the rotating shaft 9 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com