Operating method for an exhaust gas cleaning device and corresponding drive system

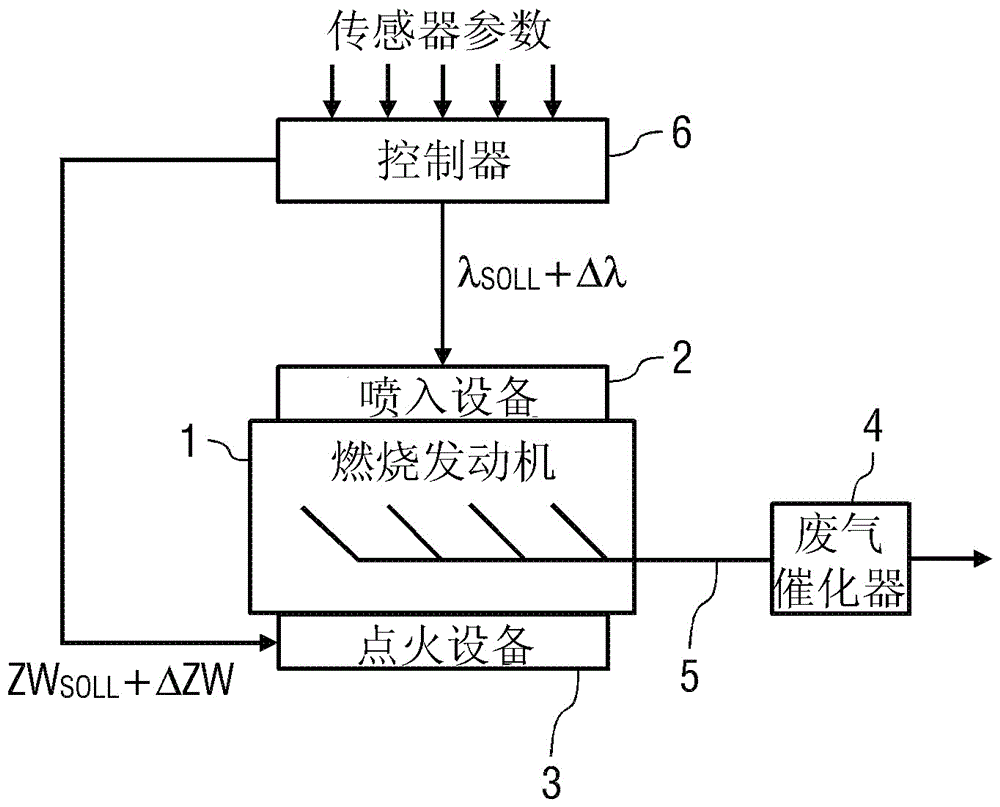

An operation method and exhaust gas purification technology, which are applied in mechanical equipment, electric control of exhaust gas treatment devices, diagnostic devices of exhaust gas treatment devices, etc., can solve problems such as the contradiction of purification goals of exhaust gas catalytic converters, and achieve the goal of improving the purification effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

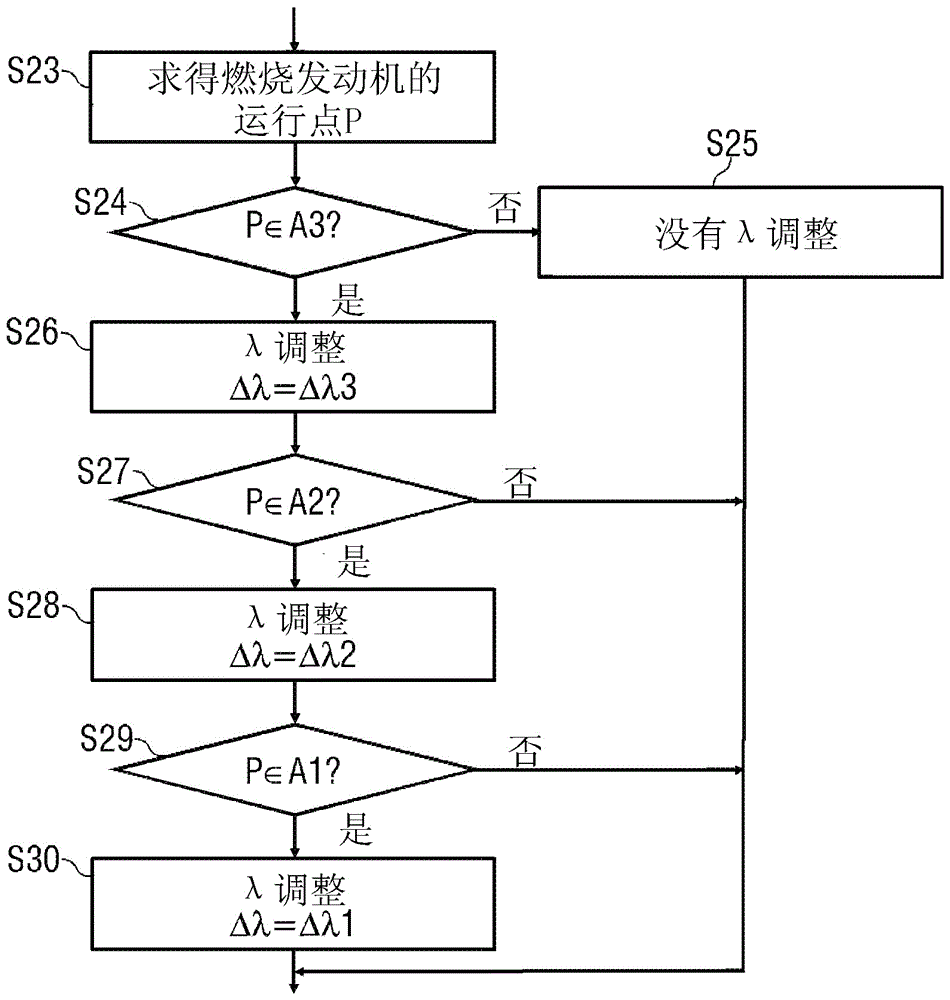

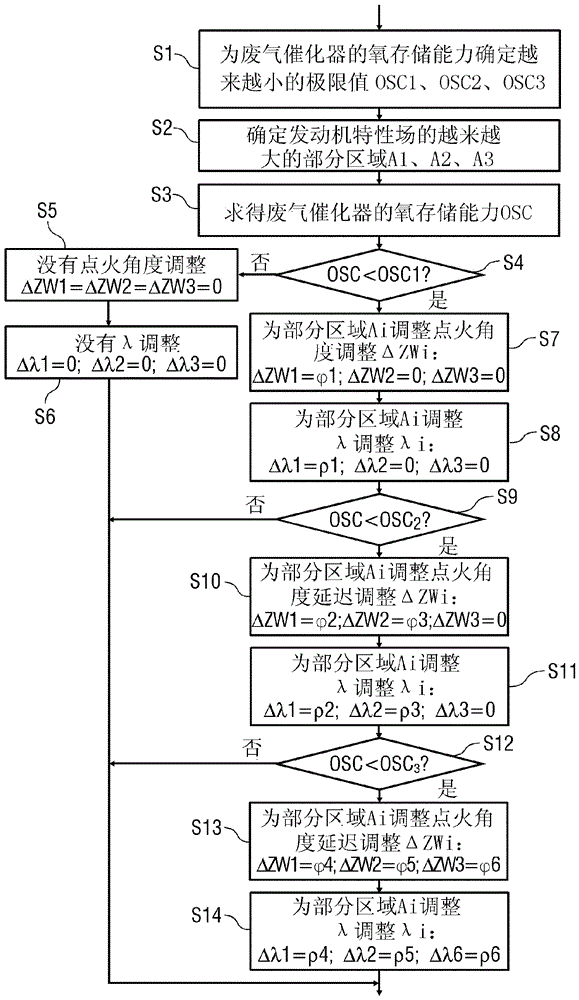

[0040] Figure 1A A flow chart is shown for explaining a part of the operating method according to the invention, which part is operated only once during a driving cycle, that is to say on the one hand with the ignition switched on and the engine started and on the other hand with the ignition switched off and the engine between stops.

[0041] In the first step S1, the oxygen storage capacity of the exhaust gas catalytic converter (OSC: O xygen S storage C apacity) to determine smaller and smaller limit values OSC1, OSC2, . . . , OSCn. Apply OSC1>OSC2>…>OSCn.

[0042] In a further step S2, increasingly larger partial areas A1, A2, . . . figure 2 is schematically shown in . For some areas A1, A2,...An, A1

[0043] The following description and figures show an example of a system with three subranges and three OSC limit values.

[0044] In step S3 , the real-time value OSC of the oxygen storage capacity of the exhaust gas catalytic converter is subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com