Treatment method for purifying and whitening barite

A treatment method and barite technology, which is applied in the field of barite purification and whitening, can solve the problems that Ca cannot be removed and affects the purity, and achieves the effects of low cost, improved purification, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

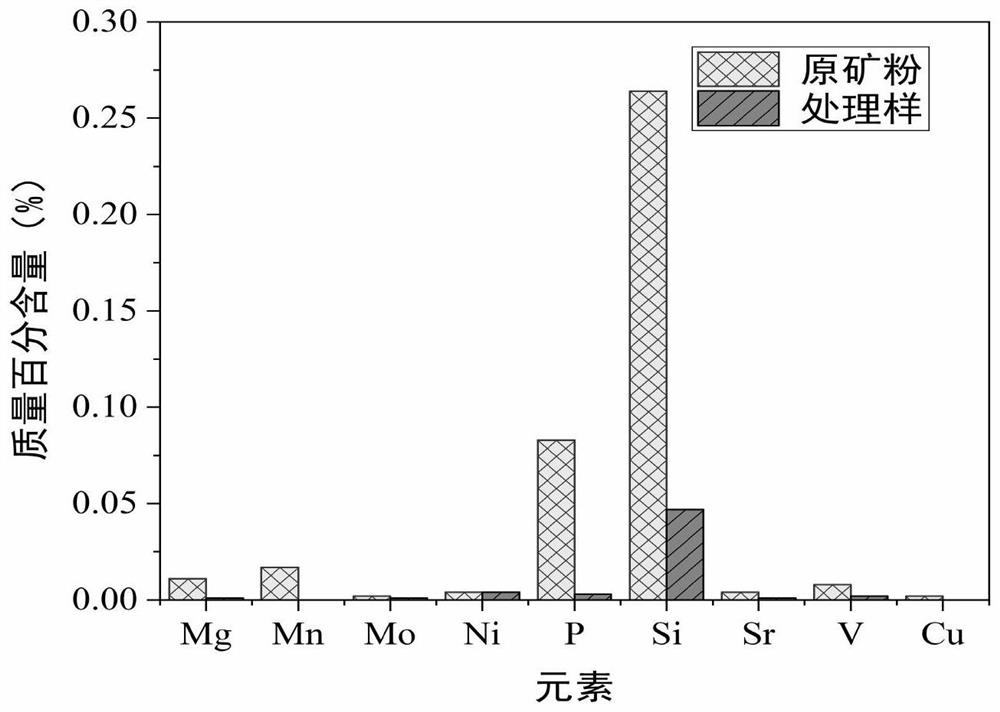

Image

Examples

Embodiment 1

[0033] This embodiment provides a treatment method for purifying and whitening barite, comprising the following steps:

[0034] Take by weighing 25g of barite powder ground into powder, and add the first complexing agent EDTA-2Na in the barite powder and mix evenly, and the mass ratio of EDTA-2Na and barite powder is 0.9%:1, obtain the first a mixture;

[0035] Slowly add the first mineral acid (hydrochloric acid with a concentration of 5mol / L) in the first mixture and mix well to obtain the second mixture, and the mass ratio of the added hydrochloric acid volume to barite powder is 5:4; the second mixture React in a water bath at 60°C for 1 hour, filter the reaction product with suction, and add 60 mL of 2 mol / l hydrochloric acid to the product obtained by suction filtration three times to wash it; then wash off the acid on the surface of the product with deionized water, and then wash it Treat at 150°C for 40 minutes to obtain preliminarily purified and whitened barite powd...

Embodiment 2

[0039] This embodiment provides a treatment method for purifying and whitening barite, and the difference between this embodiment and Embodiment 1 is that in this embodiment, the first inorganic acid is 2mol / L hydrochloric acid.

[0040] The purified and whitened barite obtained in this example was ground into powder, and the whiteness was measured with a whiteness meter. As a result, the whiteness of the purified and whitened barite in this example was 65.2%.

Embodiment 3

[0042] This embodiment provides a treatment method for purifying and whitening barite, and the difference between this embodiment and Embodiment 1 is that in this embodiment, the first inorganic acid is 3 mol / L hydrochloric acid.

[0043] The purified and whitened barite obtained in this example was ground into powder, and the whiteness was measured with a whiteness meter. As a result, the whiteness of the purified and whitened barite in this example was 66.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com