Circulating sewage treatment device

A technology of sewage treatment device and sewage treatment machine, which is applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. and other problems, to achieve the effect of reducing the cost of use, speeding up purification, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

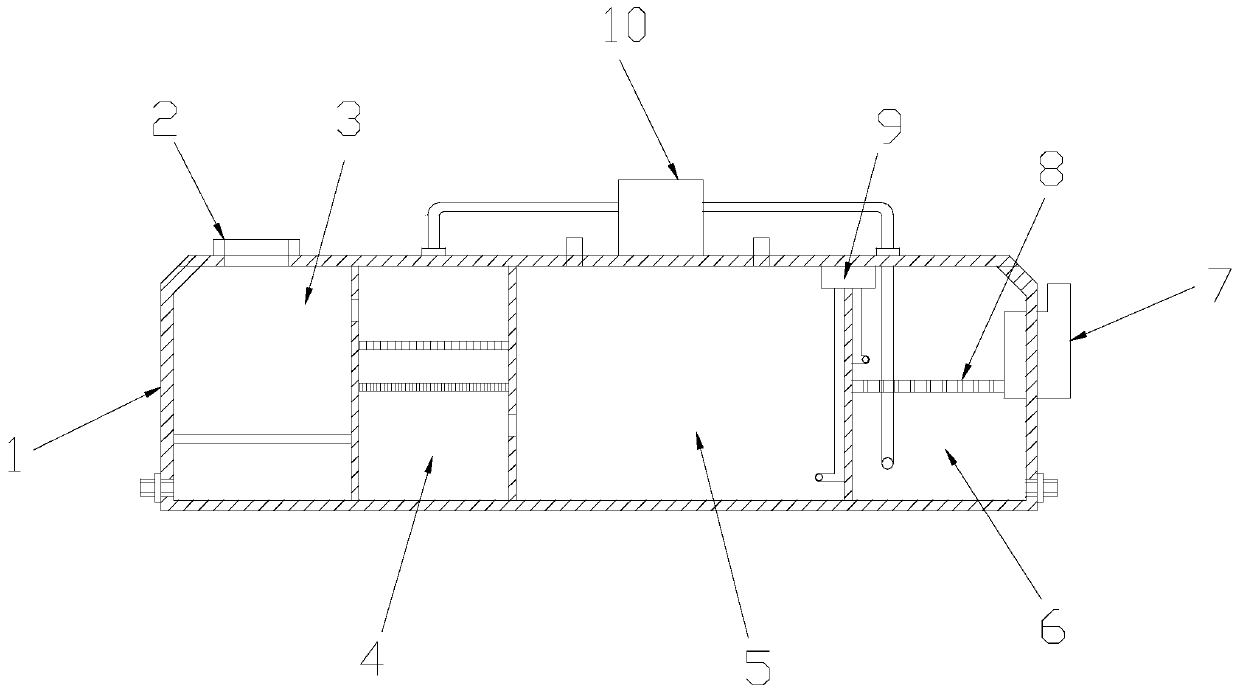

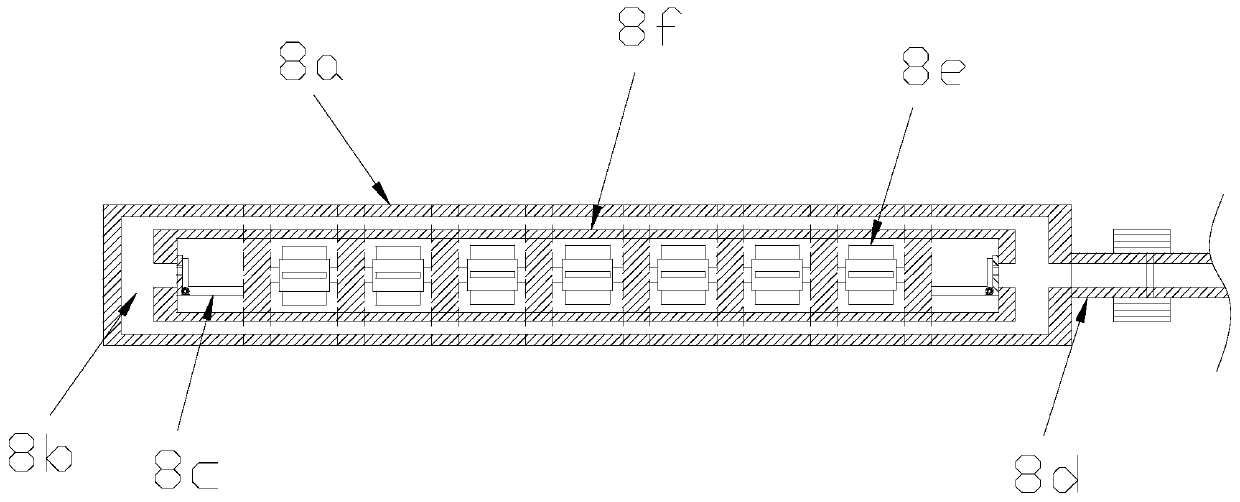

[0027] see Figure 1-Figure 4 , the present invention provides a circulating sewage treatment device, the structure of which includes a sewage treatment machine 1, an inlet pipe 2, a sedimentation tank 3, a filter tank 4, a contact oxidation tank 5, a disinfection tank 6, a liquid storage tank 7, a disinfection mechanism 8, Suction pump 9, circulating water pump 10, water inlet pipe 2 is provided on the left side of the top of the sewage treatment machine 1, the sewage treatment machine 1 and water inlet pipe 2 are fixedly connected, and the inside of the sewage treatment machine 1 is from left to The right side is provided with sedimentation tank 3, filter tank 4, contact oxidation tank 5, disinfection tank 6 successively, and described disinfection tank 6 inner wall is provided with disinfection mechanism 8, and described disinfection tank 6 and disinfection mechanism 8 are flexibly connected, and described A liquid storage tank 7 is installed on the right side of the disinf...

Embodiment 2

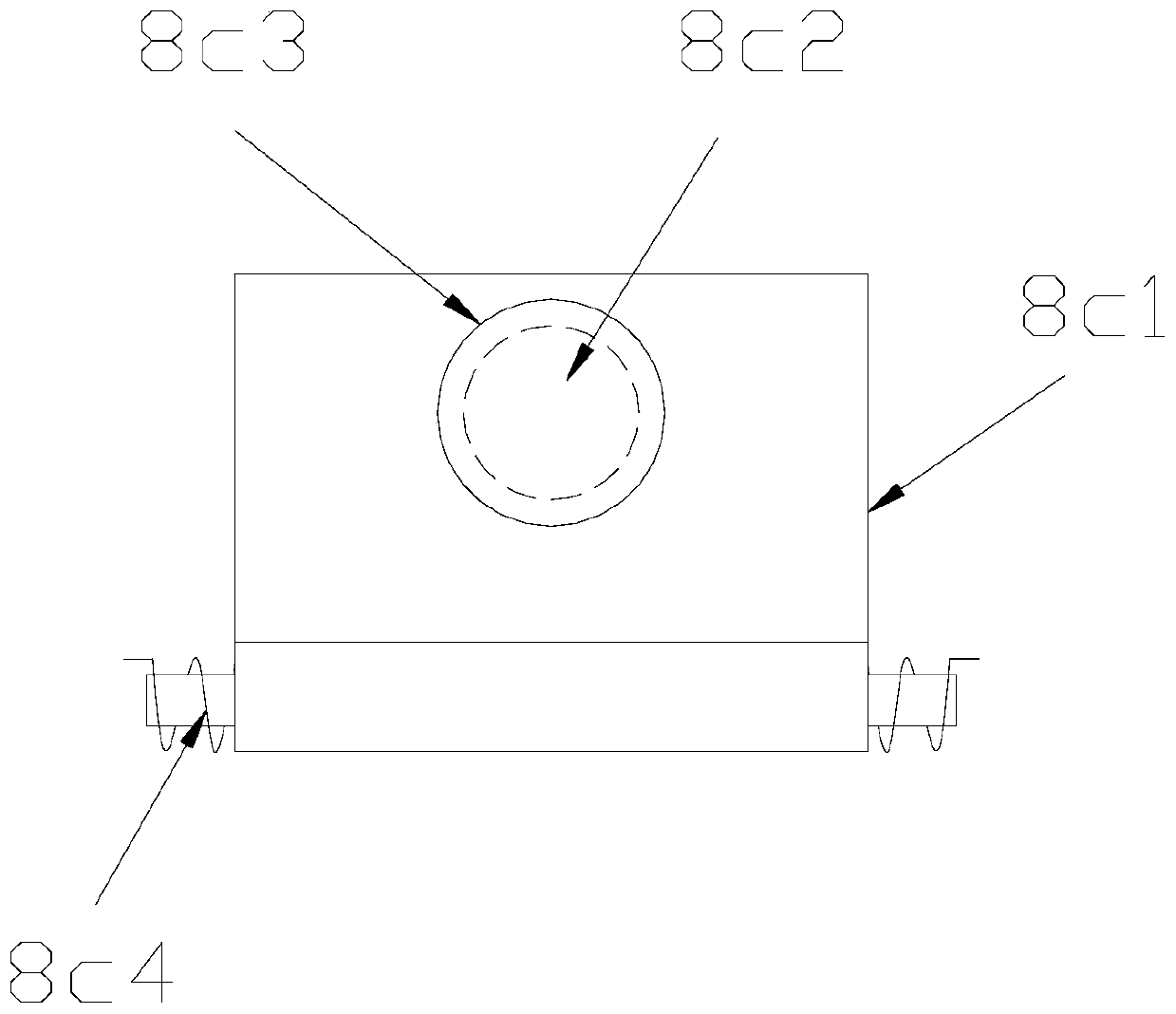

[0034] see Figure 1-Figure 6 , the present invention provides a circulating sewage treatment device, the magnetic stirring mechanism 8e is composed of a roller 8e1, a hook-shaped blade 8e2, and a rotating shaft 8e3, and the surface of the roller 8e1 is provided with more than two hook-shaped blades 8e2, the roller 8e1 is fixedly connected to the hook blade 8e2, and the left and right ends of the roller 8e1 are provided with a rotating shaft 8e3, and the roller 8e1 is connected to the rotating shaft 8e3.

[0035] The surface of the roller 8e1 is provided with an armature 8e11, and the roller 8e1 is glued to the armature 8e11.

[0036] The inner wall of the sterilizing filter plate 8a is provided with a battery bar g1, the said sterilizing filter plate 8a is fixedly connected with the battery bar g1, the inner wall of the filter hole 8f is equipped with a waterproof electromagnet g2, and the said battery bar g1 It is electrically connected with the waterproof electromagnet g2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com