A municipal sewage oxidation treatment method

A technology for oxidation treatment and urban sewage, applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. A lot of energy and other issues, to achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

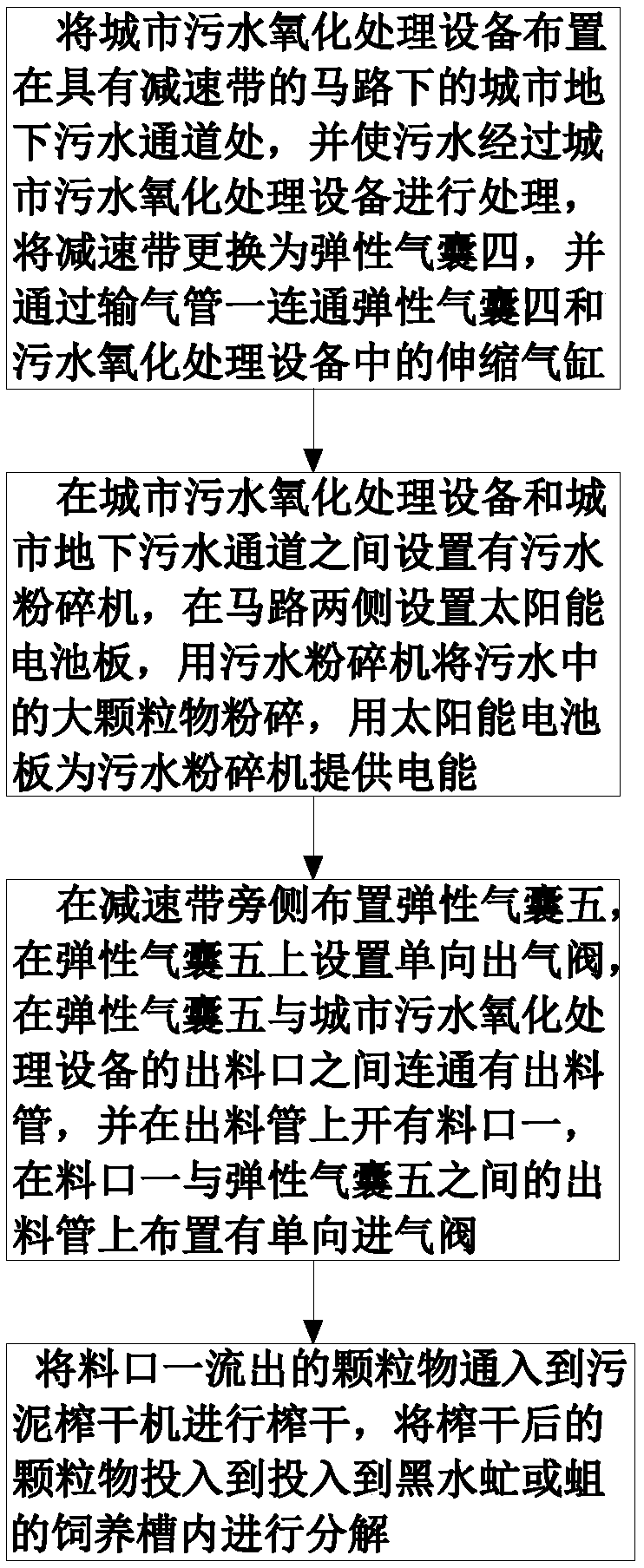

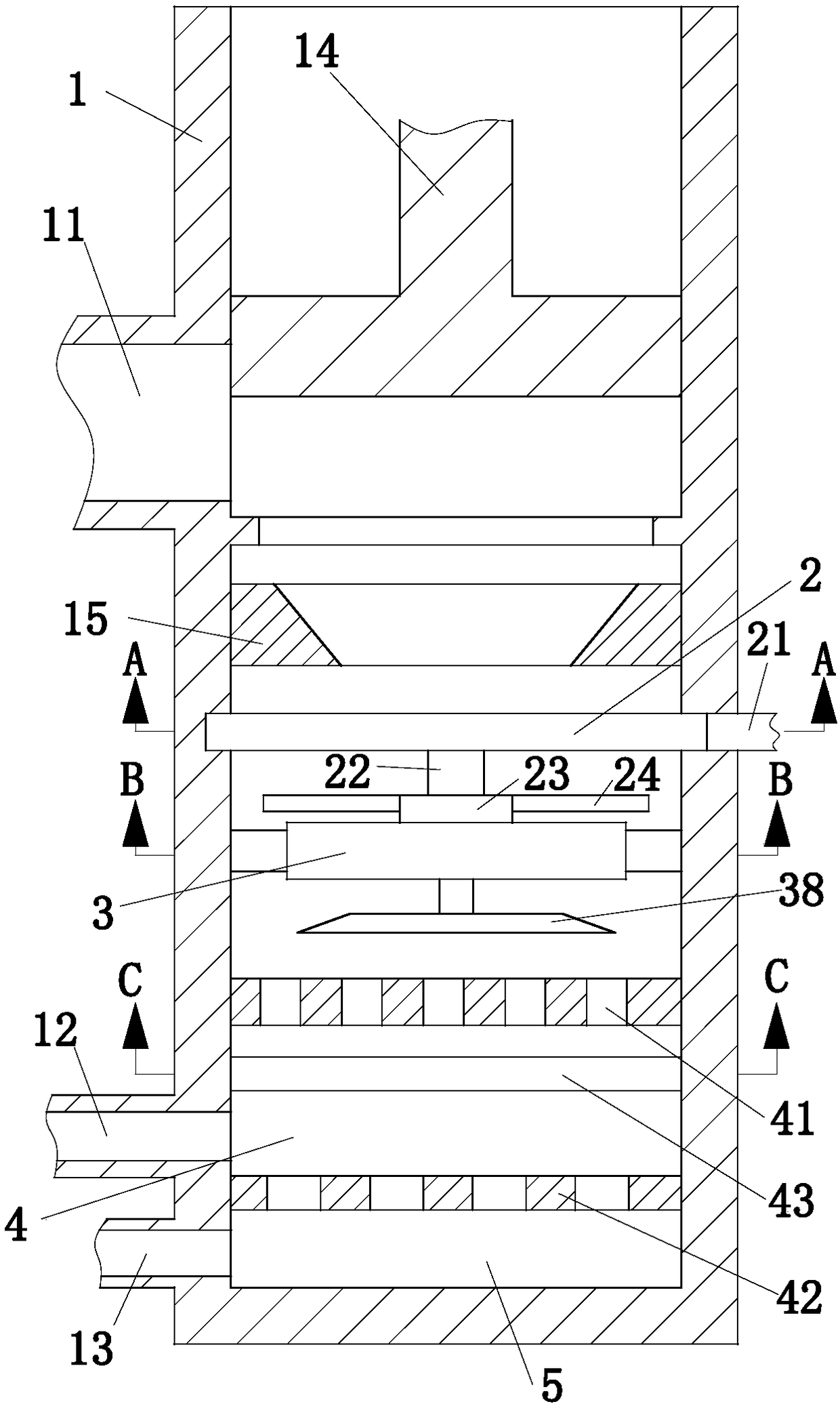

[0033] use Figure 1 to Figure 8 A municipal sewage oxidation treatment method of the present invention is described as follows.

[0034] Such as Figure 1 to Figure 5 Shown, a kind of urban sewage oxidation treatment method of the present invention, this method comprises the following steps:

[0035] S1: Arrange the urban sewage oxidation treatment equipment at the urban underground sewage channel under the road with speed bumps, and let the sewage be treated by the urban sewage oxidation treatment equipment. One is connected to the elastic airbag four and the telescopic cylinder in the urban sewage oxidation treatment equipment; when a vehicle passes by the speed bump, the elastic airbag four is compressed, and the elastic airbag four supplies air to the telescopic cylinder, so that the telescopic cylinder has power and the urban sewage oxidation treatment The normal operation of the equipment makes the urban sewage oxidation treatment equipment no need to provide addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com