A kind of rubber tree dead bark rehabilitation nutrient microcapsule and its preparation method and application

A nutrient agent, rubber tree technology, applied in the directions of botanical equipment and methods, application, horticultural methods, etc., can solve the problems of less than 30% self-sufficiency rate of natural rubber, damage to trees, etc., achieve good biocompatibility and degradability, and take effect quickly , Good slow release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

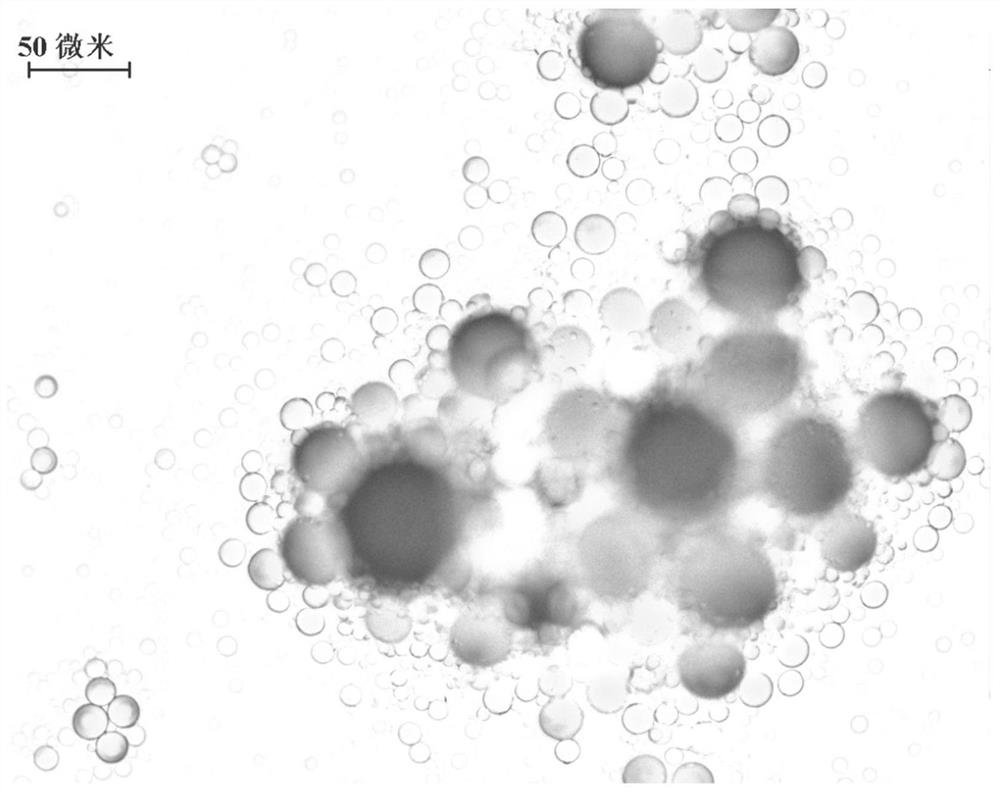

Image

Examples

Embodiment 1

[0037] The preparation of embodiment 1 rubber tree dead bark rehabilitation nutrition microcapsule

[0038] The rubber tree dead bark rehabilitation nutrient microcapsules described in this example are prepared according to the following steps:

[0039] (1) Preparation of sodium alginate solution: Accurately weigh 3g sodium alginate, add 100ml of water to dissolve, prepare a 3.0% sodium alginate solution, control the rotating speed at 500rpm / min and stir evenly at 20°C, and adjust the pH value to 5, spare;

[0040] (2) Preparation of chitosan solution: Accurately weigh 1.5g of chitosan, prepare 50ml of chitosan acetic acid solution with a mass concentration of 3.0% (the acetic acid content is 2wt%), then add 1g of rubber tree dead skin rehabilitation nutrient, 20 Control the rotation speed at 500rpm / min and stir and mix evenly at ℃. The rubber tree dead bark rehabilitation nutrient includes ammonium molybdate tetrahydrate, zinc sulfate, borax, and sodium thiosulfate in a mass...

Embodiment 2

[0046] The preparation of embodiment 2 rubber tree dead bark rehabilitation nutrition microcapsule

[0047] The rubber tree dead bark rehabilitation nutrient microcapsules described in this example are prepared according to the following steps:

[0048] (1) Preparation of sodium alginate solution: Accurately weigh 0.5g of sodium alginate, add 100ml of water to dissolve, prepare a 0.5% sodium alginate solution, control the rotation speed at 800rpm / min and stir evenly at 40°C, and adjust the pH value to 4 ,spare;

[0049] (2) Preparation of chitosan solution: Accurately weigh 0.25g of chitosan, prepare 50ml of chitosan acetic acid solution with a mass concentration of 0.5% (the acetic acid content is 0.5wt%), then add 3g of rubber tree dead bark rehabilitation nutrient, At 40°C, control the rotation speed to 800rpm / min and stir and mix evenly. The rubber tree dead skin rehabilitation nutrient includes ammonium molybdate tetrahydrate, zinc sulfate, borax and thiosulfuric acid in...

Embodiment 3

[0055] The preparation of embodiment 3 rubber tree dead bark rehabilitation nutrition microcapsule

[0056] The rubber tree dead bark rehabilitation nutrient microcapsules described in this example are prepared according to the following steps:

[0057] (1) Preparation of sodium alginate solution: Accurately weigh 1g of sodium alginate, add 100ml of water to dissolve, prepare a 1.0% sodium alginate solution, control the rotating speed at 1200rpm / min and stir evenly at 50°C, and adjust the pH value to 2, spare;

[0058] (2) Preparation of chitosan solution: Accurately weigh 0.5g of chitosan, prepare 50ml of chitosan acetic acid solution with a mass concentration of 1.0% (the acetic acid content is 1wt%), then add 3g of rubber tree dead skin rehabilitation nutrient, 50 Control the rotating speed at 1200rpm / min and stir and mix evenly at ℃. The rubber tree dead bark rehabilitation nutrient includes ammonium molybdate tetrahydrate, zinc sulfate, borax, and sodium thiosulfate in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com