Metal nozzle anticorrosion device

An anti-corrosion and nozzle technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve problems such as the inability to form electrochemical corrosion conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

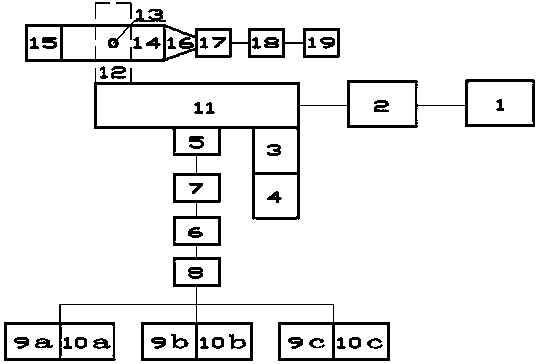

[0036] The device of the present invention consists of a pressure water source 1, a pressure water source valve 2, a liquid path low discharge port valve 3, a liquid path discharge liquid collection box 4, an anti-corrosion cleaning liquid inlet valve 5, an anti-corrosion cleaning liquid pressure pump 6, and an anti-corrosion cleaning hydraulic pressure pump. Power pipeline 7, anti-corrosion cleaning liquid suction multi-valve control pipeline 8, anti-corrosion cleaning anti-corrosion cleaning liquid storage tank 9a, anti-corrosion cleaning and anti-corrosion cleaning liquid storage tank 9b, anti-corrosion cleaning liquid storage tank 9c, No. 1 anti-corrosion Corrosion cleaning liquid 10a, No. 2 anti-corrosion cleaning liquid 10b, No. 3 anti-corrosion cleaning liquid 10c, liquid path 11, metal nozzle annular liquid path distributor 12, metal nozzle water inlet 13, metal nozzle air-water mixer 14, metal nozzle Nozzle 15, gas circuit connector 16, gas circuit 17, pressure gas sou...

Embodiment approach 2

[0049] The metal nozzle water inlet 13 has a diameter of 0.9 mm, and the metal nozzle water inlet 13 is symmetrically distributed into four;

[0050] Cationic polyacrylamide PAM was prepared into a 0.30% aqueous solution as the No. 1 cleaning solution, and Lonza polyaminopropyl biguanide was added to prepare a 21% aqueous solution as the No. 2 cleaning solution, and glycerin emulsion was added to prepare a 5% aqueous solution as the No. 3 cleaning solution. The No. 1 cleaning liquid is filled into the entire liquid circuit system one by one, and sprayed from the nozzle, so that the water molecules and air free in the entire liquid circuit system are discharged or fused into the anti-corrosion cleaning liquid, forming a metal nozzle in the contact part of the liquid One layer of anti-corrosion cleaning liquid film, other is the same as embodiment 1.

Embodiment approach 3

[0051] Embodiment 3 The metal nozzle water inlet 13 has a diameter of 0.9 mm, and the metal nozzle water inlet 13 is symmetrically distributed into six; the cationic polyacrylamide PAM is prepared into a 0.20% aqueous solution as the No. 1 cleaning solution, and Lonza polyurethane is added Propyl biguanide is prepared into a 15% aqueous solution as the No. 2 cleaning solution, and added with glycerin emulsion to prepare a 3% aqueous solution as the No. 3 cleaning solution, which is filled successively into the entire liquid system and sprayed from the nozzle to make it free in the entire liquid. The water molecules and air in the road system are discharged or fused into the anti-corrosion cleaning liquid, and a layer of anti-corrosion cleaning liquid film is formed on the contact part between the metal nozzle and the liquid. Others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com