Method for inducing phase transition of bismuth ferrite film

A bismuth ferrite and thin film technology, applied in chemical instruments and methods, ion implantation plating, crystal growth, etc., can solve the problems of limited types, small lattice mismatch, and difficulty in obtaining high-quality T-phase BFO thin films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

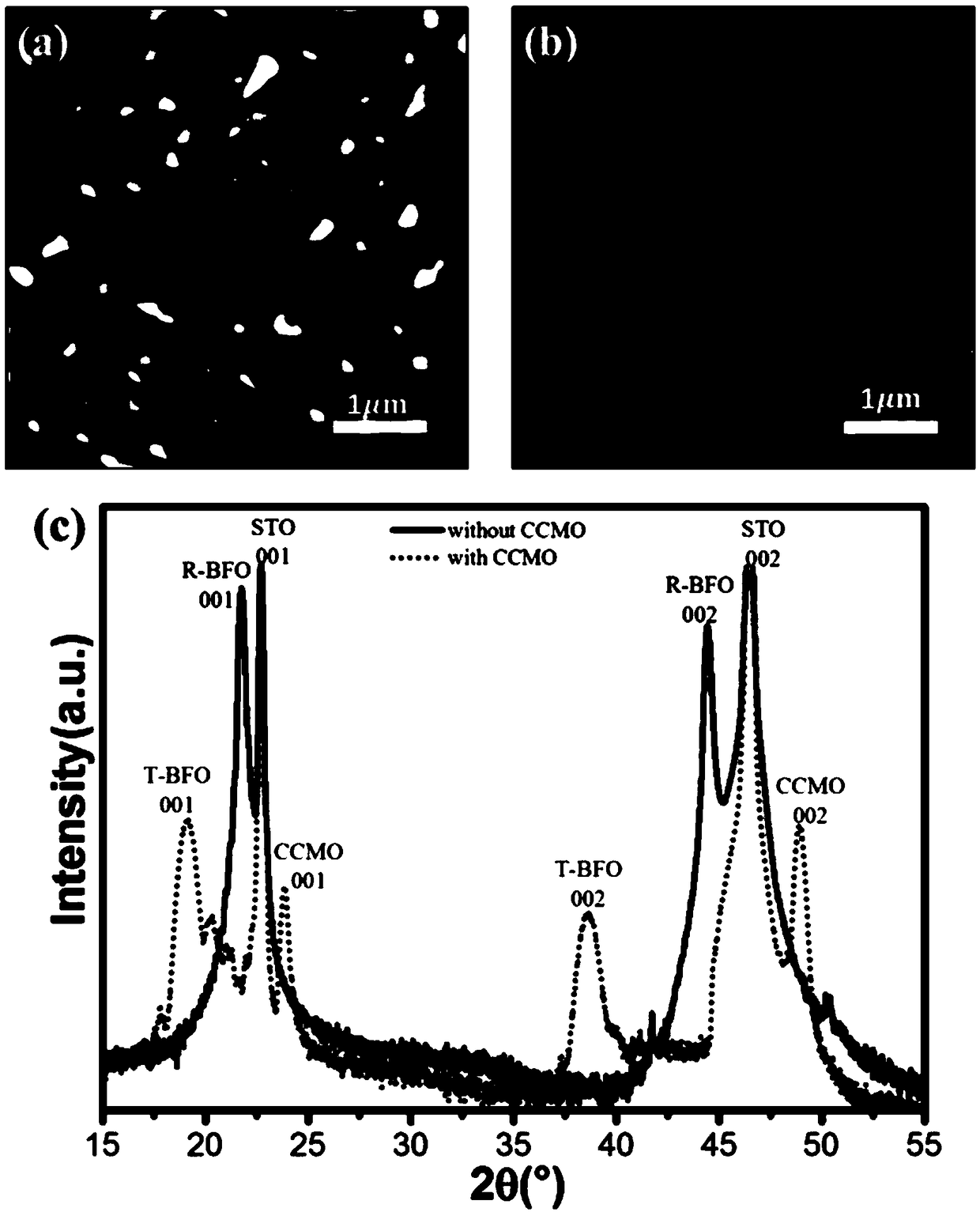

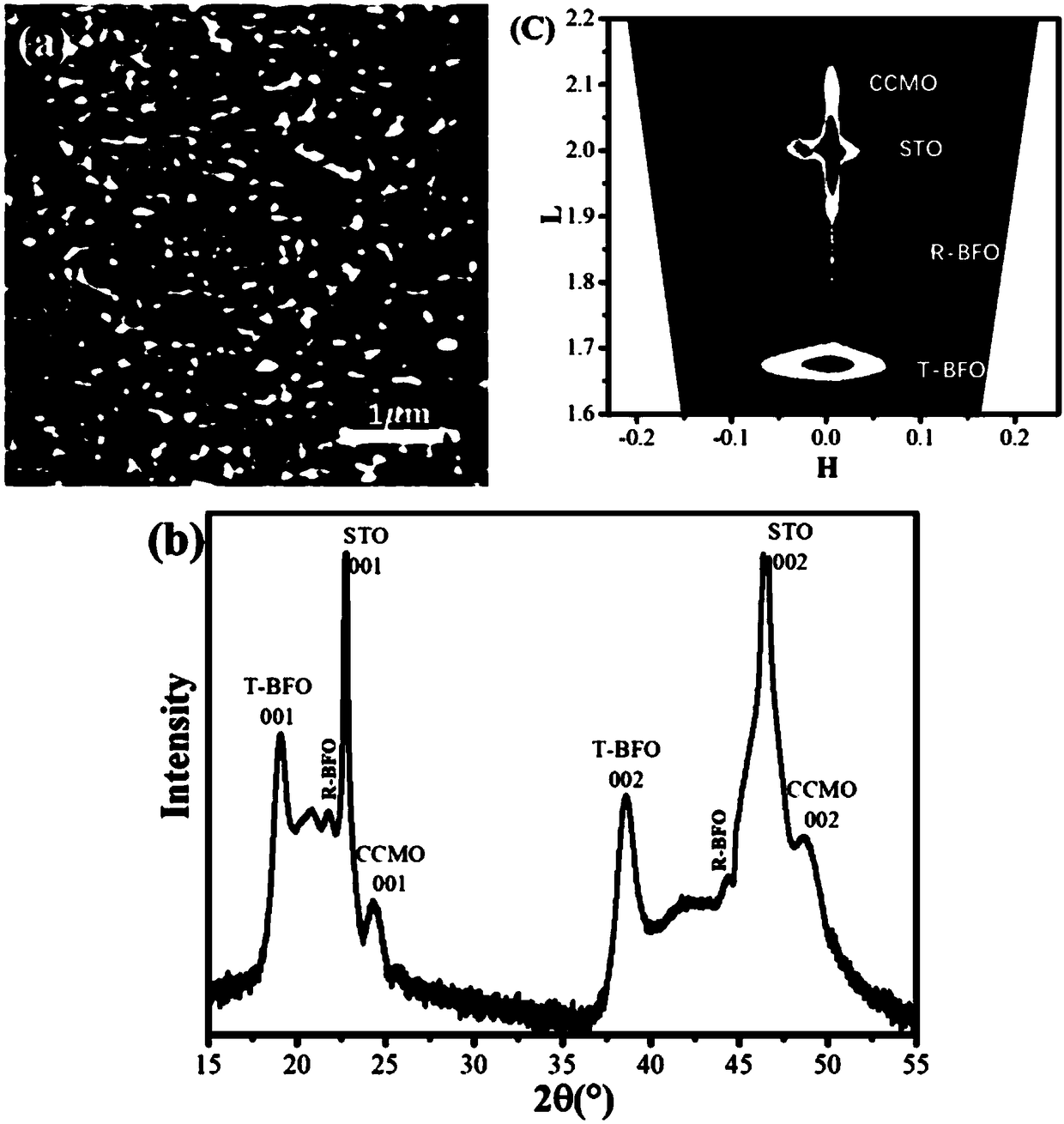

[0030] The method for inducing the phase transition of a bismuth ferrite thin film in this embodiment uses pulsed laser deposition technology to deposit CCMO and BFO on STO, specifically including the following steps:

[0031] (1) Prepare experimental materials: STO (100) substrate, CCMO target, BFO target, energy meter, silver glue;

[0032] (2) Paste the STO substrate on the heater with silver glue, apply the silver glue evenly, and bake with the heater for 2 minutes;

[0033] (3) Load the heater with the substrate fixed into the cavity, and load the CCMO target and BFO target;

[0034] (4) Vacuum to 7×10 -4 Below Pa, start to feed pure oxygen and keep it at about 15Pa;

[0035] (5) Heating to 680°C at a rate of 20°C / min;

[0036] (6) Set the number of laser pulses to 1000, irradiate the CCMO target with laser, and deposit a CCMO film with a thickness of 10nm or 50nm on the STO;

[0037] (7) Adjust the temperature of the heater to 700°C at a rate of 10°C / min, and clean t...

Embodiment 2

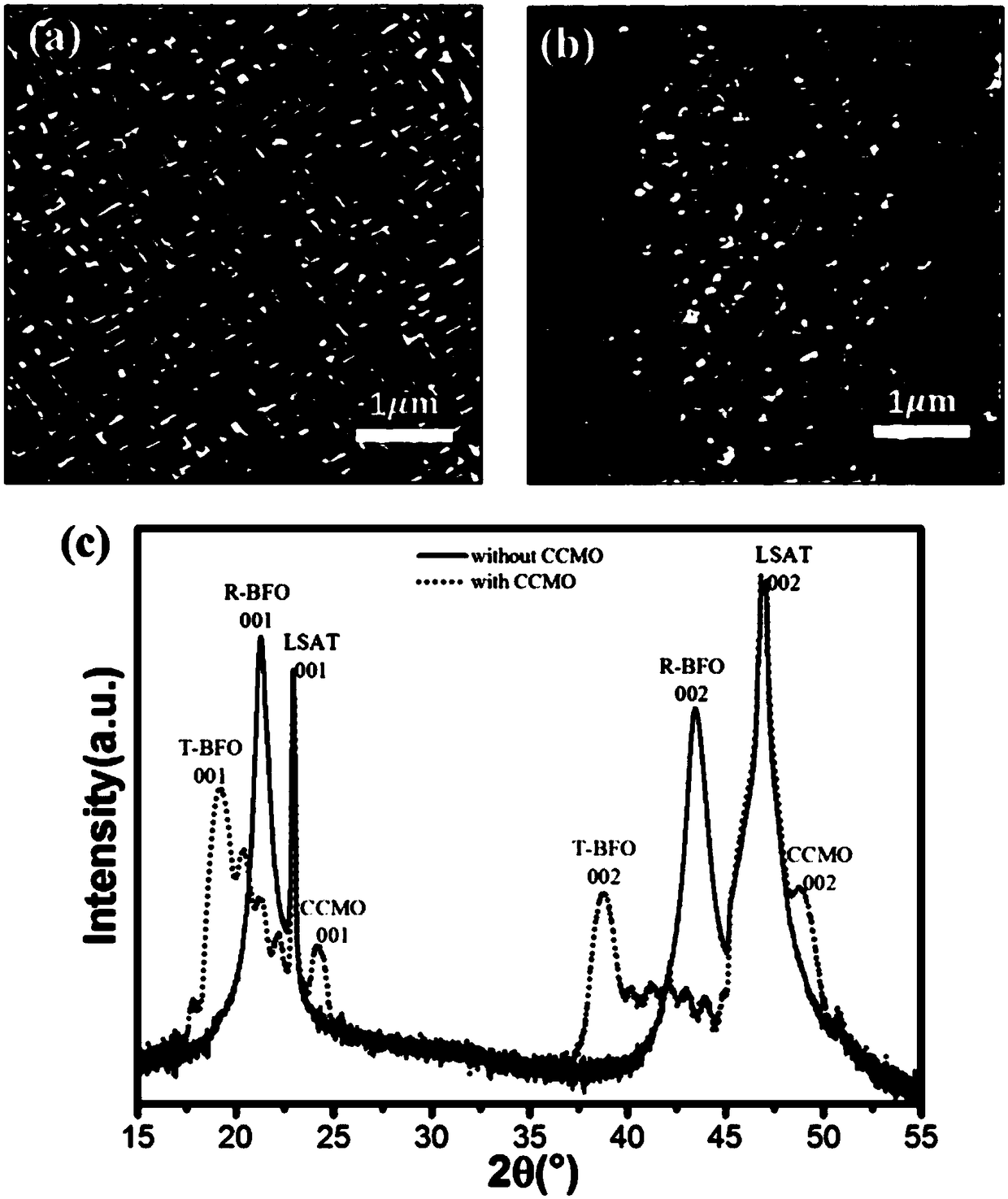

[0042] The method for inducing the phase transition of a bismuth ferrite thin film in this embodiment uses pulsed laser deposition technology to deposit CCMO and BFO on LAST, specifically including the following steps:

[0043] (1) Prepare experimental materials: LAST (100) substrate, CCMO target, BFO target, energy meter, silver glue;

[0044] (2) Paste the LAST substrate on the heater with silver glue, apply the silver glue evenly, and bake with the heater for 2 minutes;

[0045] (3) Load the heater with the substrate fixed into the cavity, and load the CCMO target and BFO target;

[0046] (4) Vacuum to 7×10 -4 Below Pa, start to feed pure oxygen and keep it at about 15Pa;

[0047] (5) Heating to 680°C at a rate of 20°C / min;

[0048] (6) Set the number of laser pulses to 1000, irradiate the CCMO target with laser, and deposit a CCMO film with a thickness of 10nm or 50nm on the LAST;

[0049] (7) Adjust the temperature of the heater to 700°C at a rate of 10°C / min, and cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com