A structurally ordered platinum-based intermetallic nanocrystal and its preparation and application at medium and low temperatures

A technology with an ordered structure and nanocrystals, applied in structural parts, nanotechnology, nanotechnology, etc., can solve problems such as the reduction of the electrochemical specific surface of catalyst nanoparticles, the easy dissolution of transition metals, and the high energy consumption of technical routes. Achieve the effects of increased electrochemical active area, easy industrialization, and smaller size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

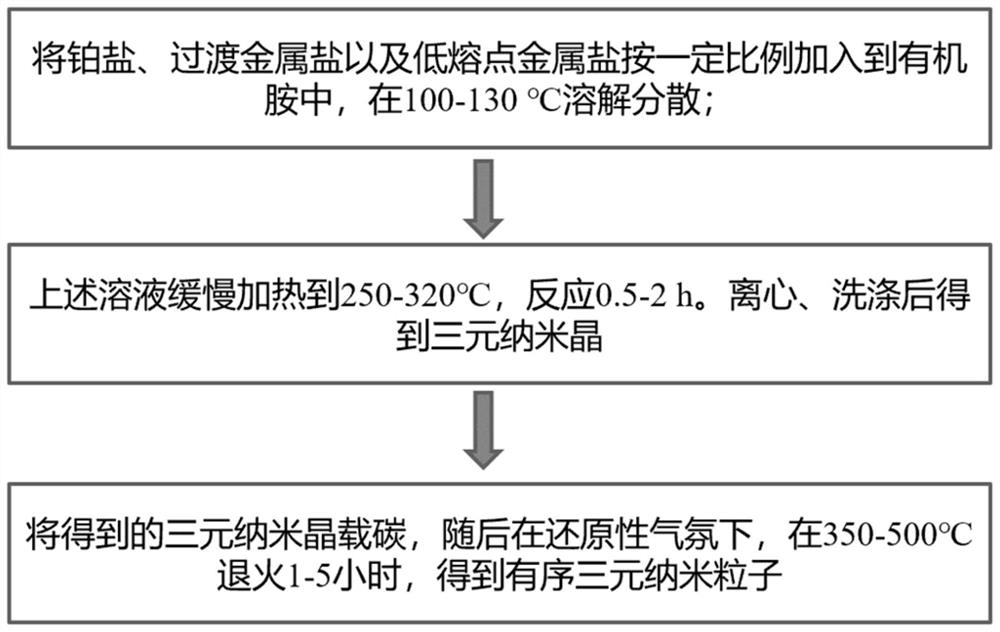

Method used

Image

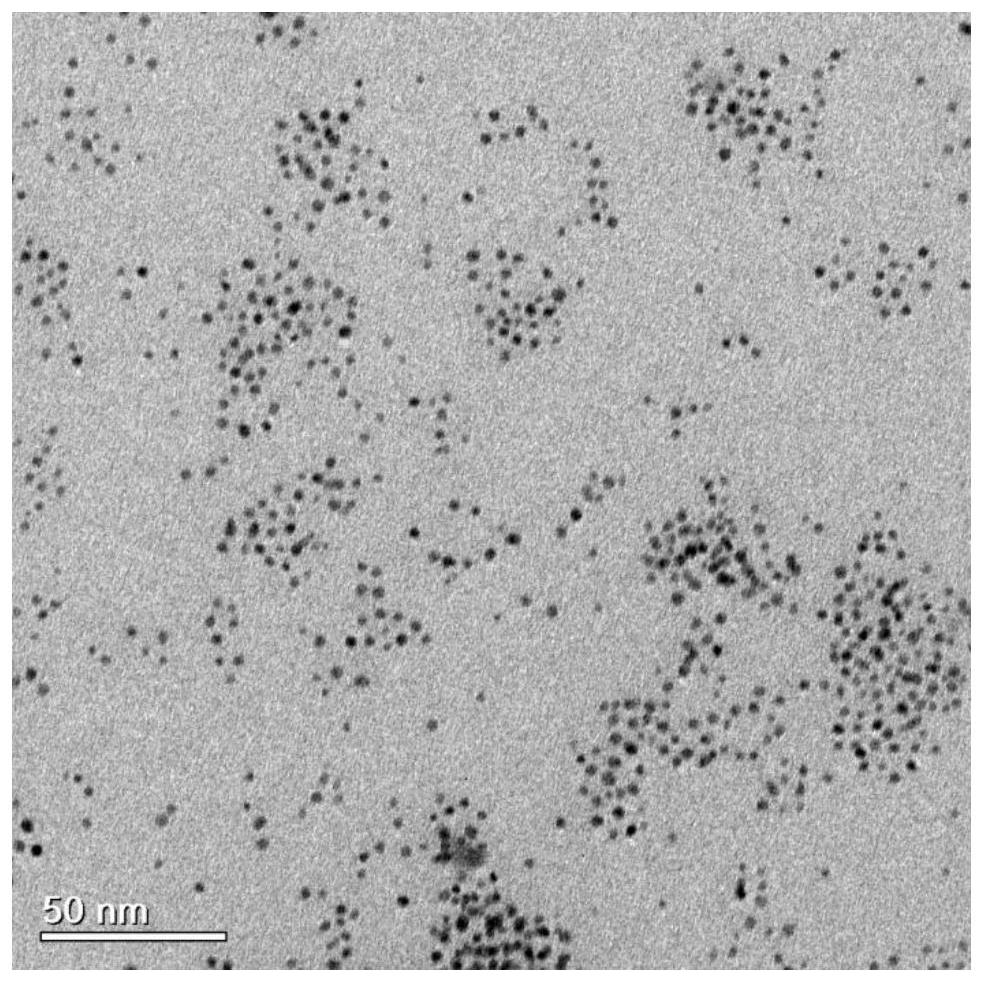

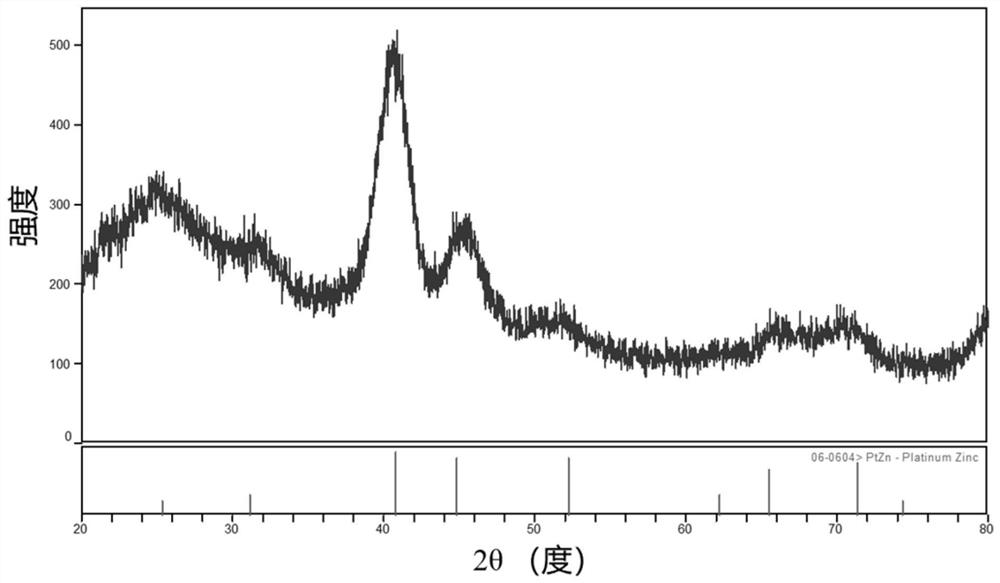

Examples

Embodiment 1

[0045] S1: According to the molar ratio of 5: 4: 1, acetyl acetinate platinum, acetylacetone zinc, and dibutyldiacetyltin, and dissolved in a 5 mL olelamine solution, mounted to a platinum precursor concentration of 0.01 mol / L The solution. Under argon, the solution was stirred at 110 ° C for 20 minutes, and the precursor salt was fully dissolved.

[0046] S2: Subsequently, the solution was raised to 320 ° C at a heating rate of 10 ° C / min, and the reaction was continued for 2 hours, then centrifuged, and nanoparticles disordered platinum zinc tin.

[0047] S3: The carbon powder having a certain mass of 15% is weighed with a mixture of ethanol and a mixture of ethanol and hexanes having a volume ratio of 2: 1, and the ultrasonic dispersion is subsequently dropped. Non-nanoparticles. After a period of time, centrifugation, washing, drying, to obtain carbon-free disfrunitable platinum zinc tin three-dimensional nanoparticles;

[0048] S4: The obtained carbon-free platinum zinc t...

Embodiment 2

[0050] S1: According to the molar ratio of 50:35:15, acetyl acetinate platinum, acetylacetone nickel, and dibutyl diacetinyltin, and dissolved in a 5 mL olelamine solution, formulated into a platinum precursor concentration of 0.05 mol / L The solution. Under argon, the solution was stirred at 100 ° C for 20 minutes, and the precursor salt was fully dissolved.

[0051] S2: Subsequently, the solution was warmed to 260 ° C at a heating rate of 5 ° C / min, and the reaction was continued for 1 hour, then centrifugation was washed, and the disprofer platinum nickel tin three dollars were obtained;

[0052] S3: The carbon powder having a certain mass of 20% is weighed with a mixture of ethanol and hexane volume ratio of 2: 1, and the ultrasonic dispersion is subsequently dispersed, and then slowly dropped into step S2 obtained from the disprising platinum nickel tin three. Non-nanoparticles. After a period of time, centrifugation, washing, drying, to obtain carbon-free disprise platinu...

Embodiment 3

[0055] S1: According to the molar ratio of 50: 45: 5, acetyl acetiptiplatin, iron acetate, and dibutyl diacetatetin, and dissolved in a 5 mL olelamine solution, formulated into a platinum precursor concentration of 0.01 mol / L Solution. Under argon, the solution was stirred at 130 ° C for 20 minutes, and the precursor salt was sufficiently dissolved.

[0056] S2: Subsequently, the solution was warmed to 260 ° C at a temperature rise rate of 5 ° C / min, and the reaction was continued for 1 hour, then centrifuged, resulting in disorderly platinum iron tin three-dimensional nanoparticles;

[0057] S3: The toner of a certain mass of 10% is weighed with a mixture of ethanol and a mixture of ethanol and hexanes having a volume ratio of 2: 1, and the ultrasonic dispersion is subsequently dripped into step S2. Platinum Tin 3. Non-nanoparticles. After a period of time, centrifugation, washing, drying, to obtain carbon-free disorderly platinum iron tin three-dimensional nanoparticles;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com