Oxygen-vacancy Li3VO4 negative electrode material for lithium-ion battery and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems such as low tap density and large irreversible capacity loss, achieve low cost, improve electrochemical performance, reduce phase The effect of variable energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A kind of oxygen vacancy Li provided by the embodiment of the present invention 3 VO 4 The preparation method of lithium ion battery negative electrode material, comprises the following steps:

[0029] S1, vanadium pentoxide (V 2 o 5 ) and lithium hydroxide hydrate (LiOH·H 2 O) stirring the reaction in ethanol solution, then drying to obtain the precursor.

[0030] In a preferred embodiment, in this step, the molar ratio of vanadium pentoxide to lithium hydroxide hydrate is 1˜1.2:6. More preferably, the molar ratio of vanadium pentoxide to lithium hydroxide hydrate is 1.1:6. A slight excess of vanadium pentoxide can speed up the reaction rate.

[0031] In a preferred embodiment, in this step, the ethanol solution is ethanol and water in a volume ratio of 3-4:1. The stirring reaction time is 5~7h. Choose V 2 o 5 and LiOH·H 2 O is used as a raw material, and the cost is relatively low. More importantly, LiOH·H 2 The reducing property of O contributes to the fo...

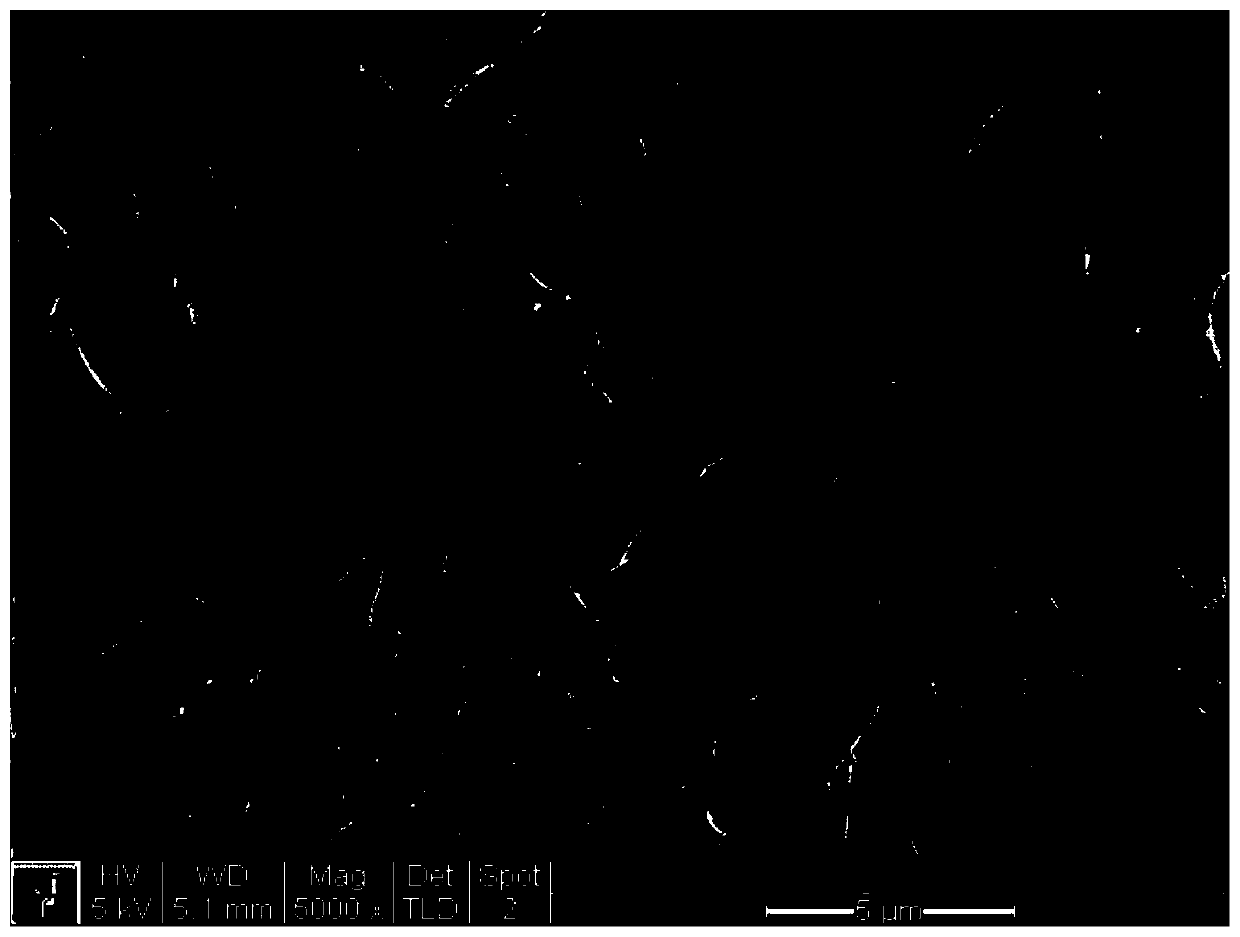

Embodiment 1

[0047] An oxygen vacancy Li provided in this embodiment 3 VO 4 Lithium-ion battery negative electrode material is prepared according to the following steps:

[0048] (1) Put V 2 o 5 and LiOH·H 2 O was stirred in an ethanol solution at a molar ratio of 1.1:6 for 6 h, and then dried in an oven at 50 °C to obtain a precursor powder.

[0049] (2) Ball milling the precursor powder for 3 hours under the condition of 50-150 r / min to obtain a ground product.

[0050] (3) The ground product was sintered at 600 °C for 2 h to obtain the oxygen vacancy Li 3 VO 4 Lithium-ion battery anode material.

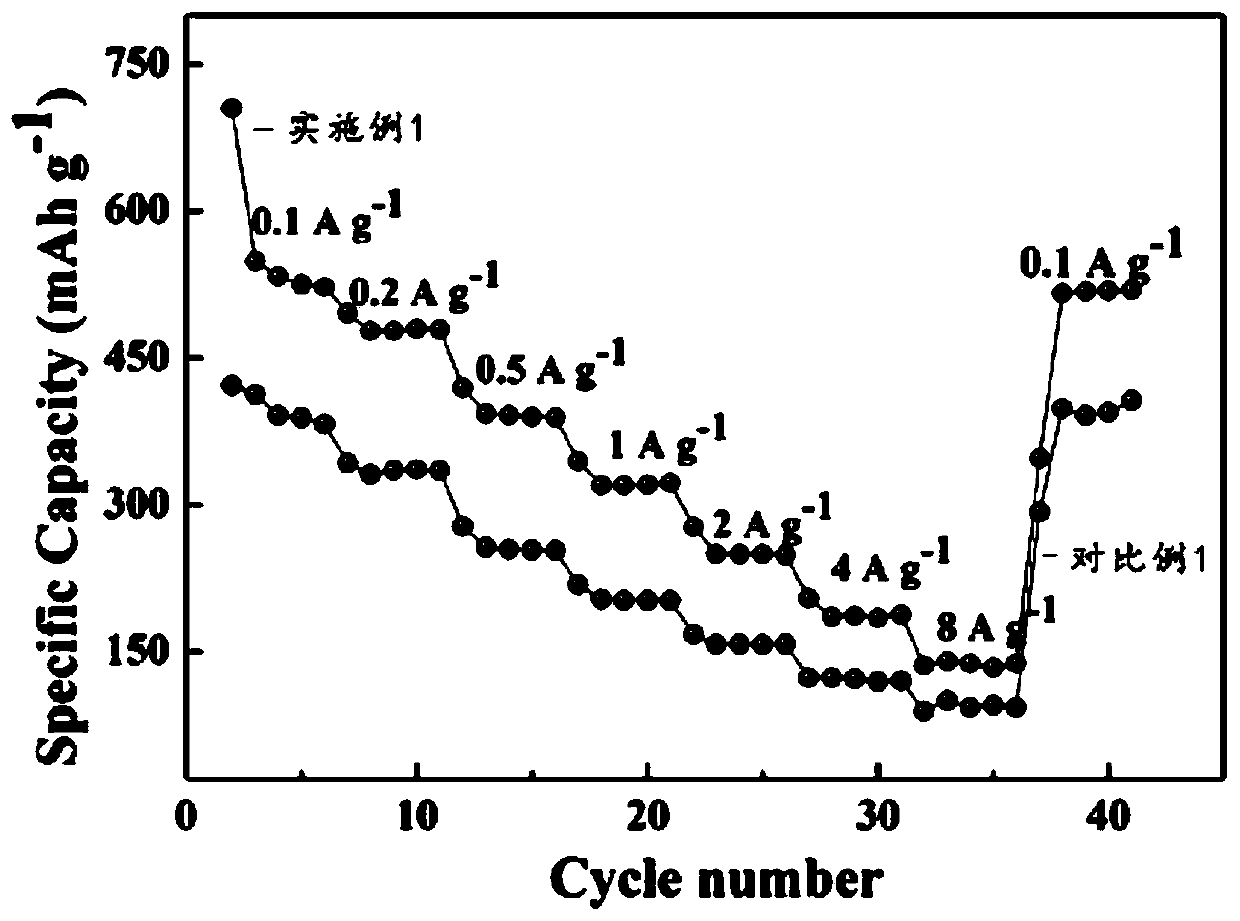

[0051] The first coulombic efficiency of the prepared sample was 79%, 1Ag -1 Under the current density, the capacity is still maintained at 414mAh g after 200 cycles -1 .

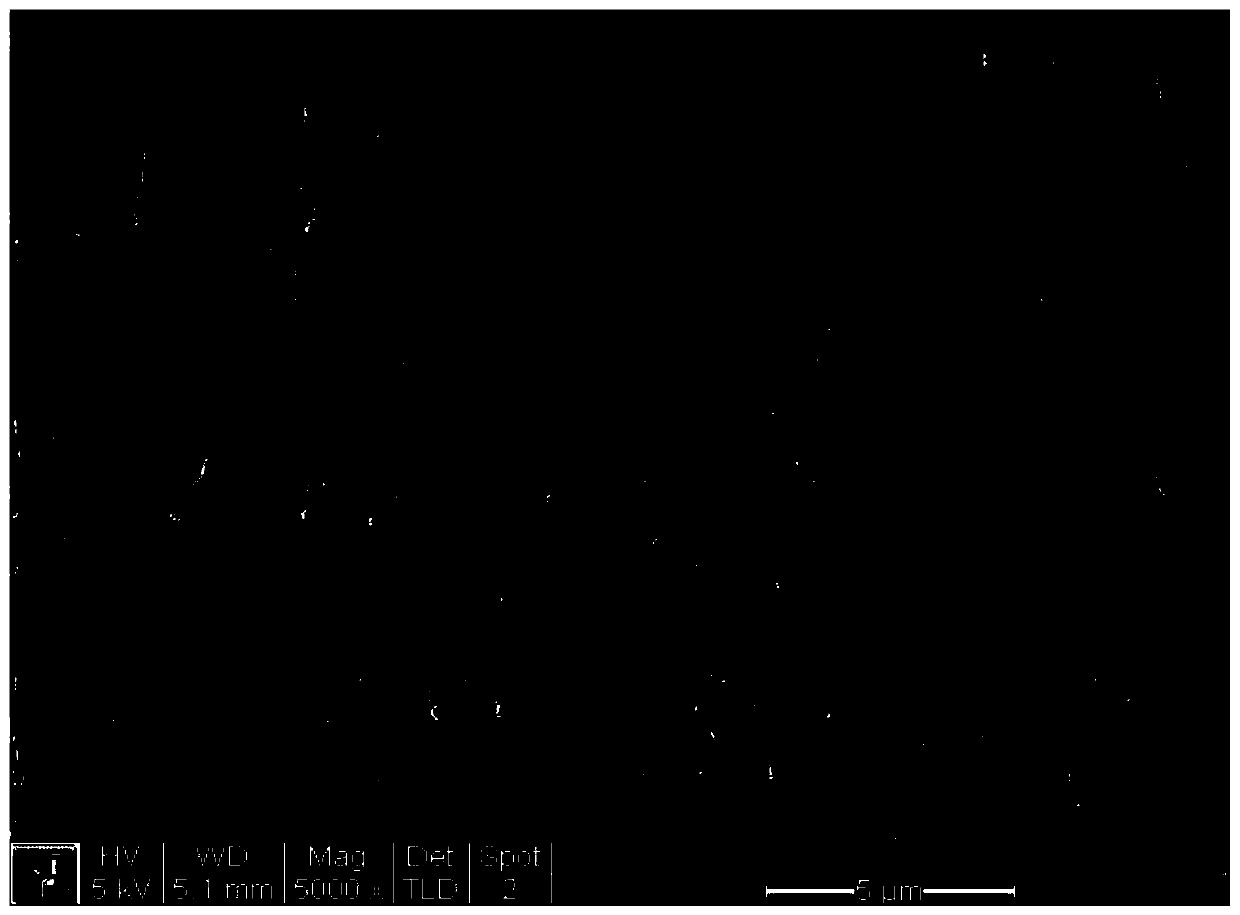

Embodiment 2

[0053] An oxygen vacancy Li provided in this embodiment 3 VO 4 Lithium-ion battery negative electrode material is prepared according to the following steps:

[0054] (1) Put V 2 o 5 and LiOH·H 2 O was stirred in an ethanol solution at a molar ratio of 1.1:6 for 6 h, and then dried in an oven at 50 °C to obtain a precursor powder.

[0055] (2) Ball mill the precursor powder for 1.5 h under the condition of 100 r / min, then add polyethylene glycol with a mass fraction of 1.5%, and ball mill for 1.5 h under the condition of 250 r / min.

[0056] (3) The ground product was sintered at 600 °C for 2 h to obtain the oxygen vacancy Li 3 VO 4 Lithium-ion battery anode material.

[0057] Add conductive agent and binder PVdF and NMP as solvent, control the content of various solid substances in the slurry to be Li 3 VO 4 :Super P:PVdF=80:10:10, using copper sheets as current collectors to prepare electrodes and assemble them into button cells for measurement, the first Coulombic ef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com