Platinum alloy nanocrystalline catalyst, and preparation method and application thereof

A technology of nanocrystals and catalysts, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of catalyst nanoparticle agglomeration, reduction of electrochemical specific surface area, increase of preparation cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

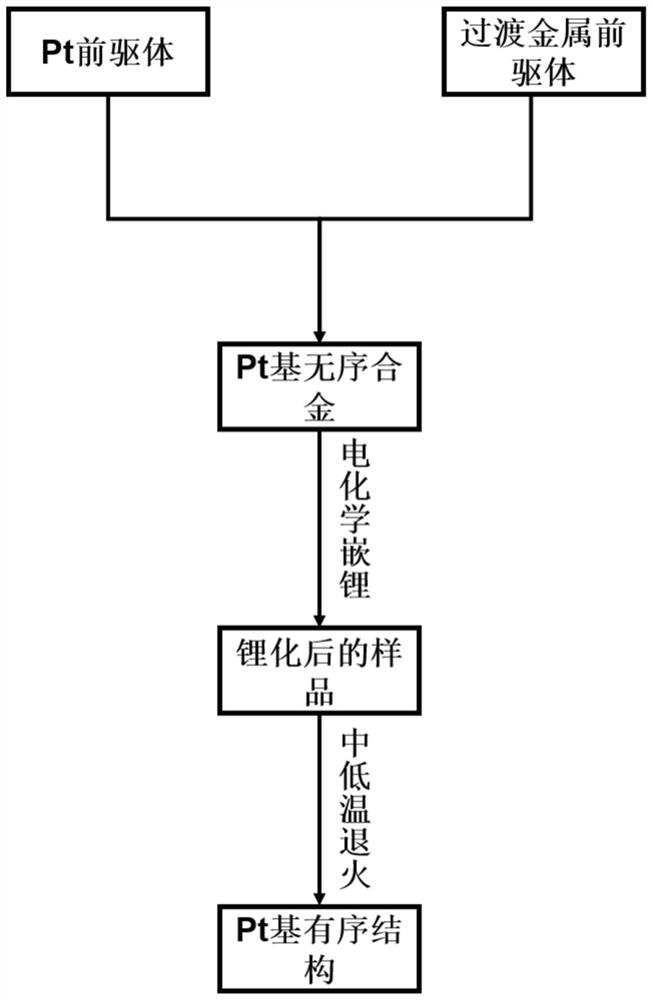

[0029] The preparation method of the platinum alloy nanocrystal catalyst provided by the invention, the preparation method first synthesizes disordered face-centered cubic structure platinum-based alloy nanocrystal (hereinafter referred to as fcc-PtFe) by the method of organic phase synthesis, and then fcc-PtFe The nanocrystal is used as the positive electrode of the lithium-ion battery, and the metal lithium sheet is used as the negative electrode of the lithium-ion battery to assemble a complete lithium-ion battery. The charging and discharging process is carried out in the voltage range of 0-2.4V, and the lithium intercalation amount in the positive electrode nanocrystalline material is controlled by controlling the discharging time. The invention reduces the bonding strength between metal atoms in the alloy by electrochemically inserting lithium into PtFe, increases the number of vacancies in the nanocrystal, and reduces the activation energy of phase transition.

[0030] ...

Embodiment 1

[0041] see figure 1 , Embodiment 1 of the present invention comprises the following steps:

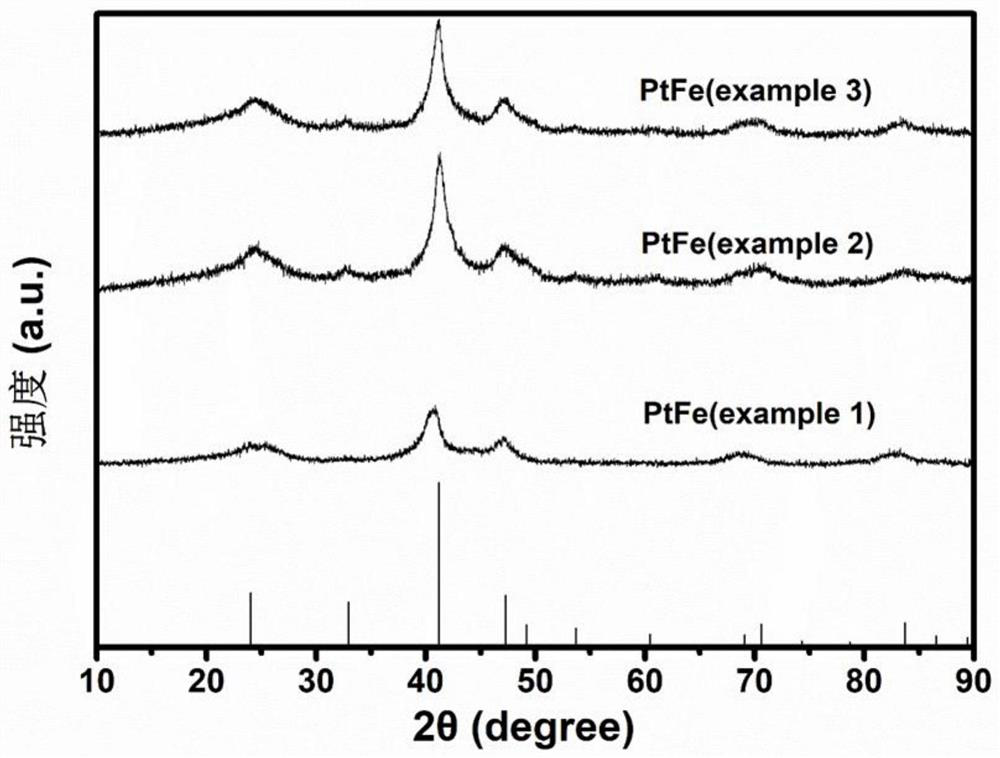

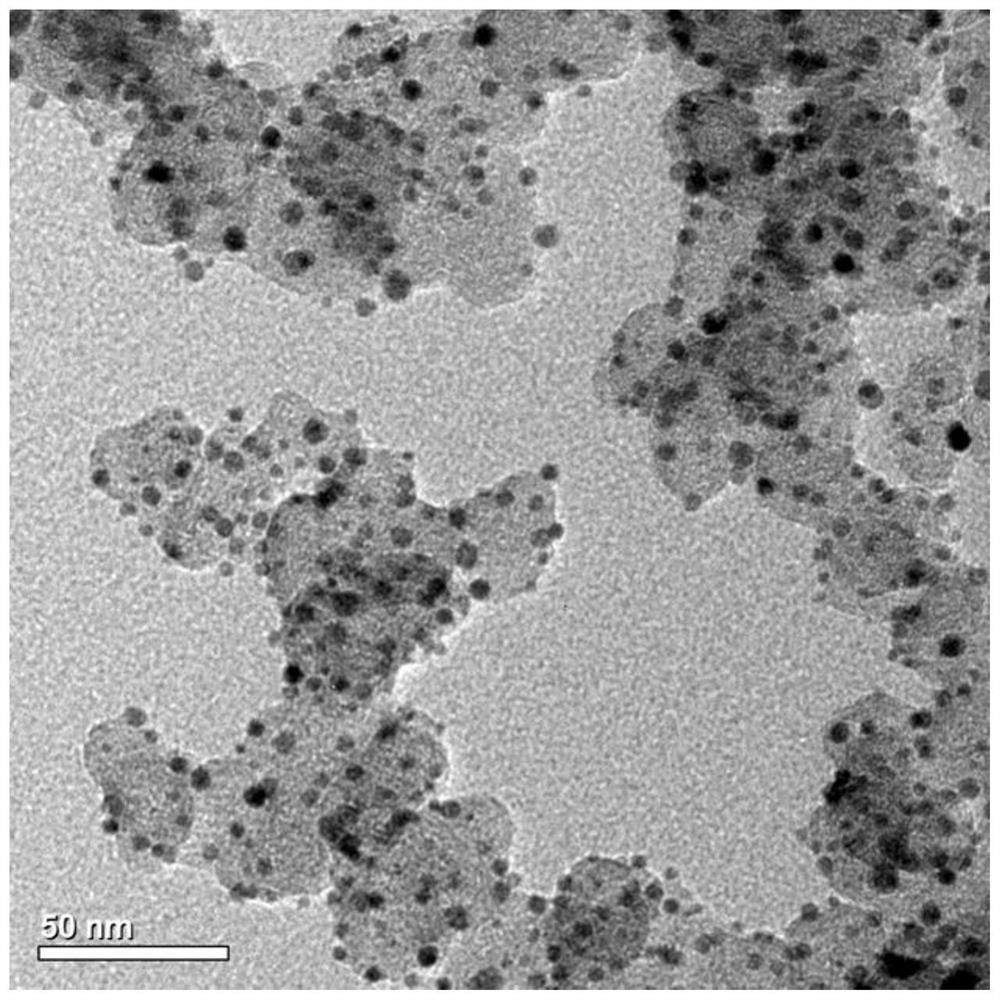

[0042] S1: Weigh 0.05mmol of platinum acetylacetonate and 0.05mmol of iron acetylacetonate and dissolve them in 5ml of oleylamine, and place the resulting solution under N 2 In the atmosphere, react at 300°C for 1h. The fcc-PtFe powder was subsequently washed by centrifugation, and the obtained powder was dissolved in n-hexane. Weigh 72 mg of carbon powder XC-72 and disperse it in a mixed solvent of n-hexane and ethanol for 0.5 h, then add the fcc-PtFe powder dispersed in n-hexane dropwise into the mixed solvent, and continue to sonicate for 1 h. Then the solvent was centrifugally washed and dried to obtain the fcc-PtFe alloy supported on XC-72.

[0043] S2: Weigh 24 mg of the final sample obtained in step S1 and 6 mg of sodium alginate into a mortar, drop in an appropriate amount of ultrapure water, and grind the powder evenly. The obtained slurry was coated on a flat copper foil, a...

Embodiment 2

[0046] The sample synthesis steps S1 and S2 in this example are the same as the steps S1 and S2 in Example 1.

[0047] S3: After step S2 is assembled, the button battery is in the potential window of 0-2.4V at 100mA g -1 The current density charge and discharge cycles 5 times, and then discharge at the same current density for 1.5h. The lithium-intercalated button battery is disassembled, and the positive electrode material of the battery is soaked in the polycarbonate solution for 12 hours, and the electrolyte remaining on the surface of the positive electrode material is washed away. Subsequently, the soaked positive electrode material was transferred to ultrapure water for ultrasonication for 2 minutes, at which point the positive electrode material had completely fallen off from the copper foil and was dispersed in the ultrapure water. Then, suction filtration, washing, and drying obtain the PtFe nanocrystals after lithium intercalation, and place the obtained nanocrystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com