Helium turbine casing structure

A technology of air intake casing and turbine casing, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc. It can solve the problems of large and not compact casing mechanism, achieve good assembly and disassembly, improve the initial temperature of intake air, and ensure safety The effect of reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

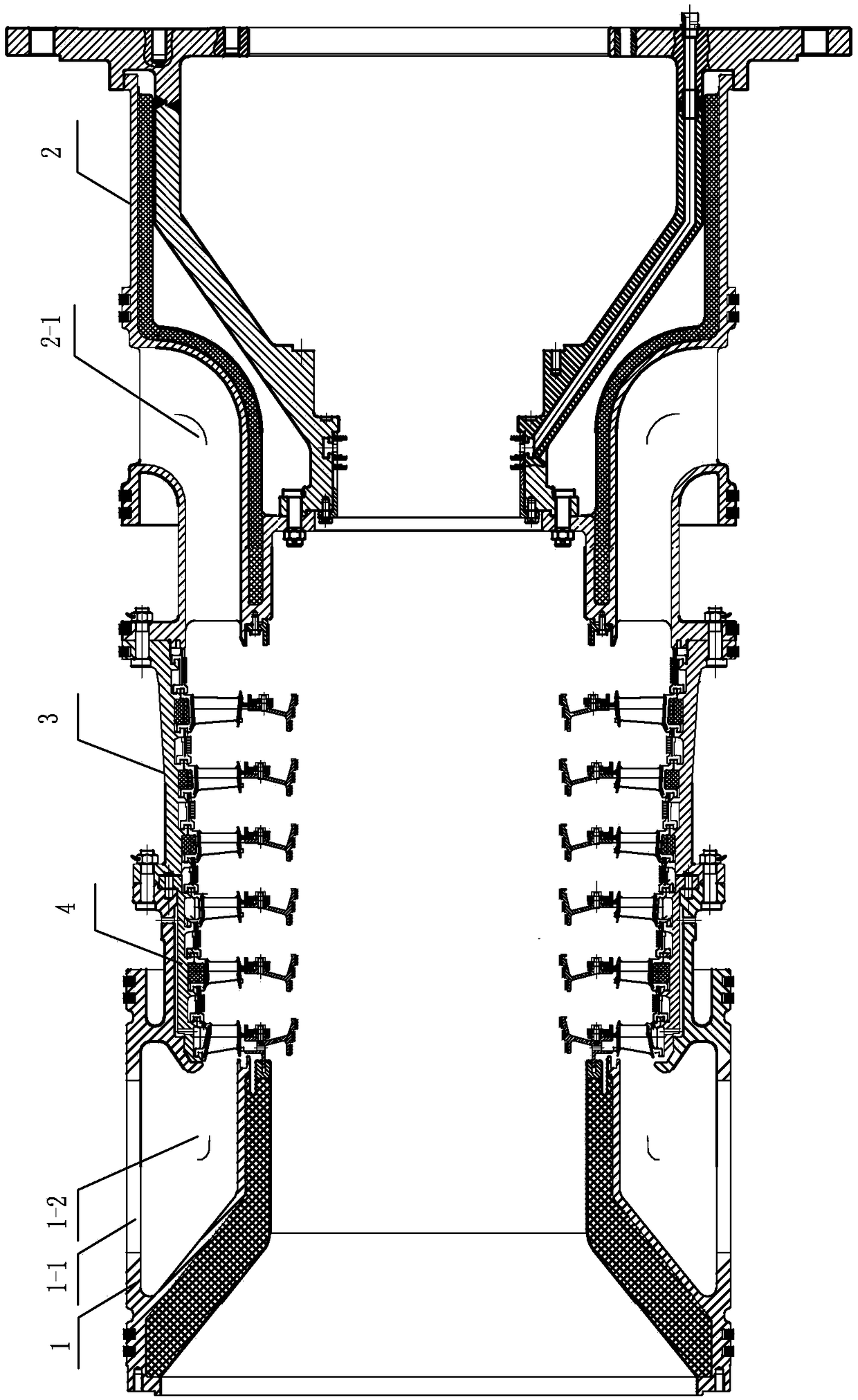

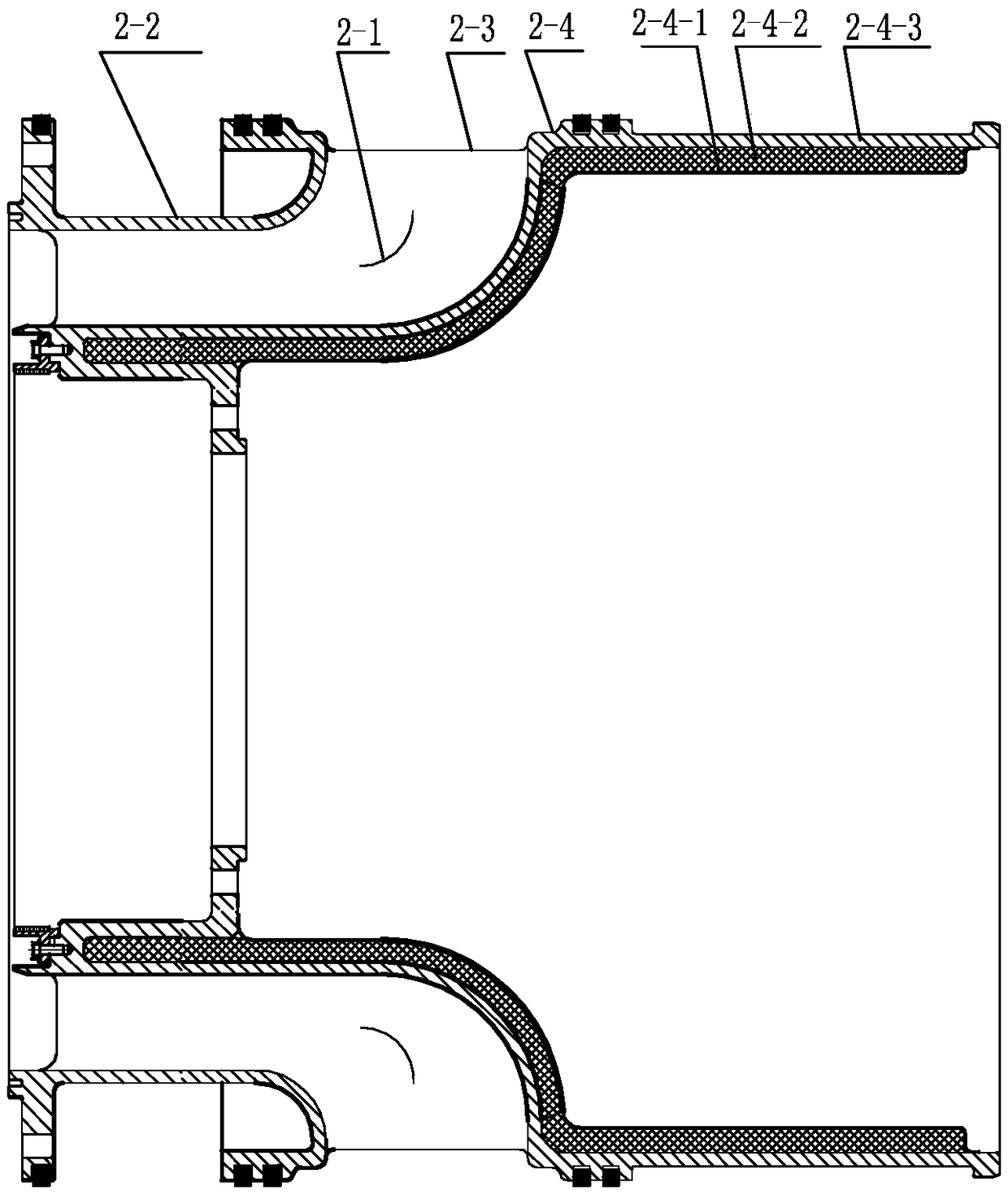

[0021] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, this embodiment includes intake casing 1, inner casing 4, exhaust casing 2 and turbine casing 3, intake casing 1, turbine casing 3, exhaust casing 2 are connected end to end in sequence, the inner The casing 4 is installed in the inside of the intake casing 1, and the upper surface and the lower surface of the intake casing 1 are respectively provided with an air inlet 1-1, and the air inlet 1-1 is connected with the air inlet casing 1. The cavity forms an air intake passage 1-2, and the outer wall of the exhaust casing 2 is provided with a plurality of air outlet passages 2-1 along the circumferential direction. The intake casing has no intake guide plate, and the intake port 1-1 can make the gas flow more smoothly and increase the intake volume. The connection of intake casing, turbine casing and exhaust casing adopts a bolt tension structure, which is easy to assemble and disas...

specific Embodiment approach 2

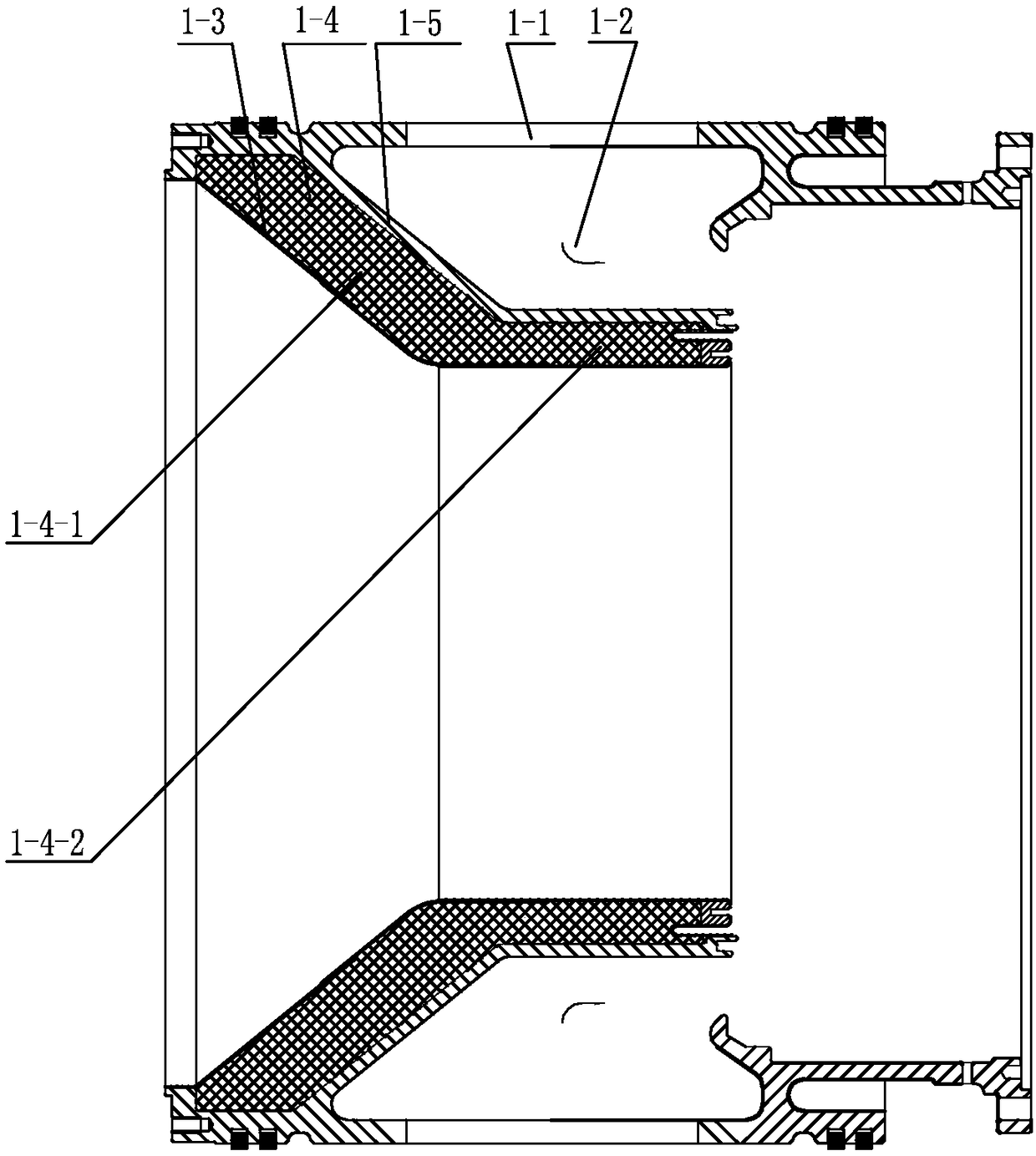

[0022] Specific implementation mode two: combination Figure 1 to Figure 3 Describe this embodiment, the air intake casing 1 of this embodiment includes a first steel plate 1-3, a first heat insulation layer 1-4 and an intake volute 1-5, a first steel plate 1-3, a first heat insulation layer Layers 1-4 and intake volutes 1-5 are arranged sequentially from inside to outside. Other compositions and connections are the same as in the first embodiment. The air intake casing with thermal insulation structure can meet the strength requirements of use, achieve the required heat insulation effect, ensure that the initial temperature of the inlet meets the design temperature, and ensure that it can work safely and reliably under high temperature for a long time. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination Figure 1 to Figure 3 To illustrate this embodiment, the thickness of the inclined section 1-4-1 of the first thermal insulation layer 1-4 in this embodiment is greater than the thickness of the horizontal section 1-4-2. Other compositions and connections are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com