Fully automatic probe detection bench and probe positioning module thereof

A technology of probe detection and positioning mode, applied in the direction of measuring electricity, measuring device, measuring electrical variables, etc., can solve the problems of low efficiency and difficulty in aligning the needle with the probe card, and achieve high detection efficiency without affecting the performance of the workbench. High-resolution imaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

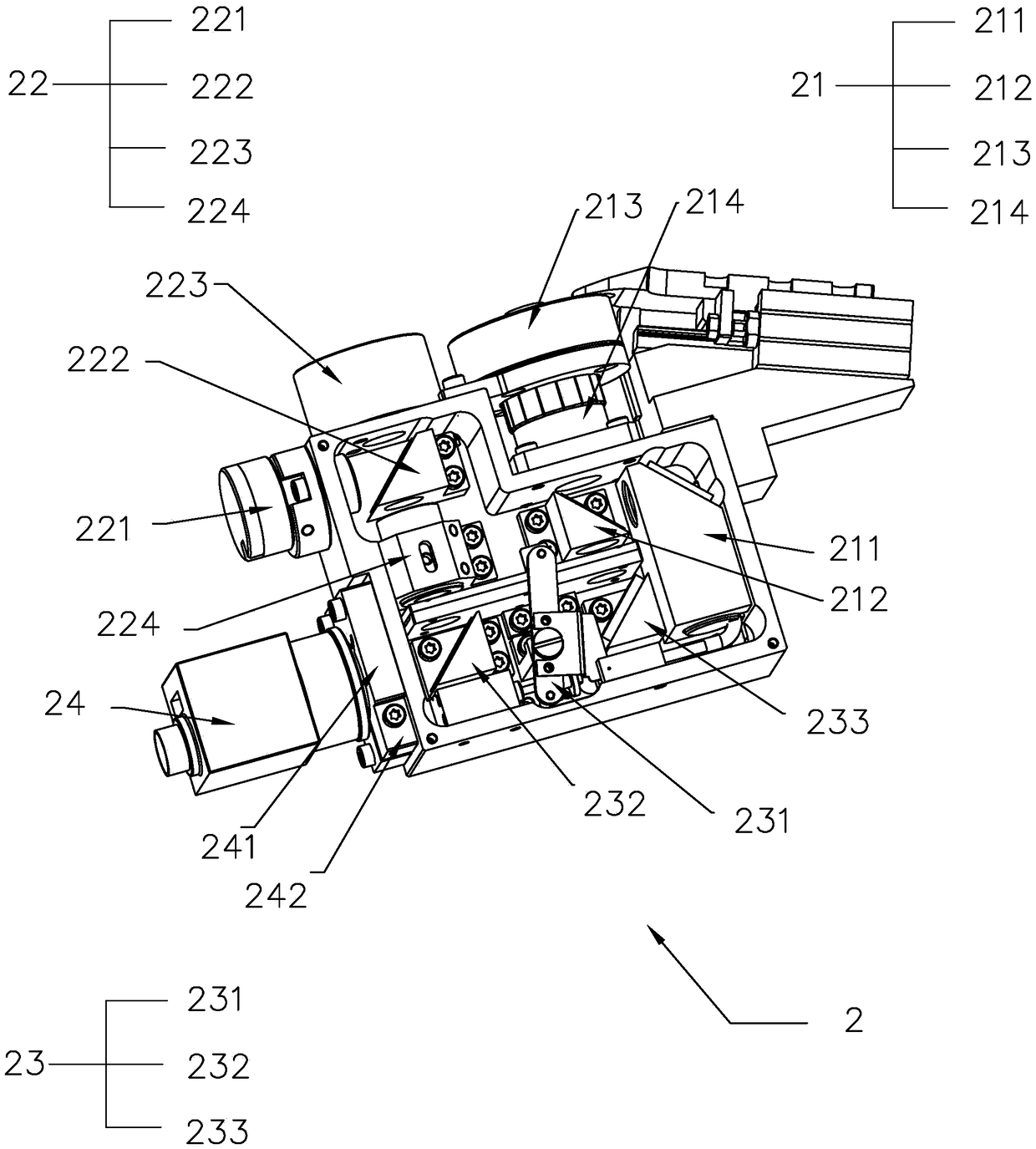

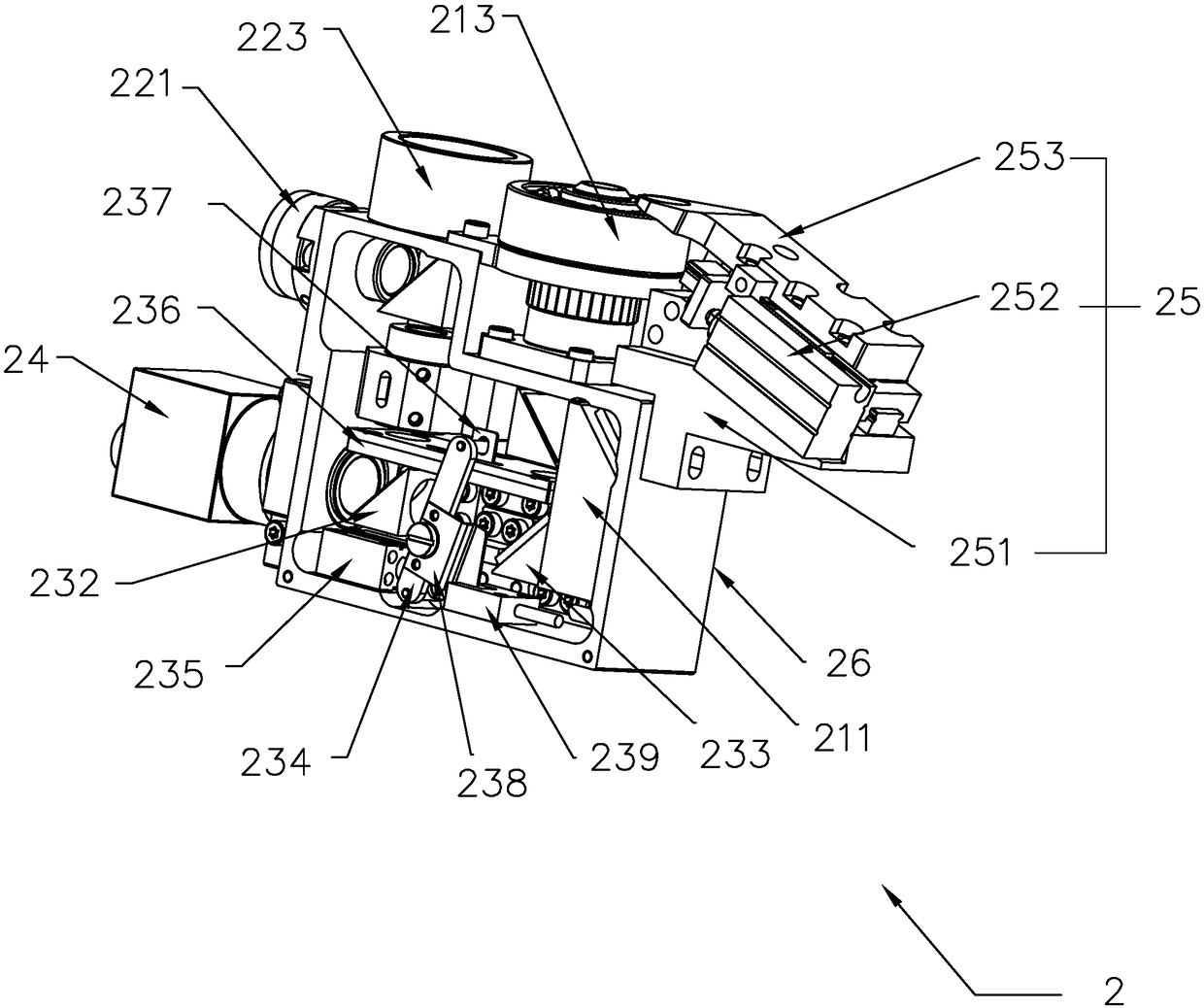

[0047] Embodiment 1: A probe positioning module, refer to figure 1 and figure 2 , comprising a probe detection box 26 fixed on the workbench, the probe detection box 26 is provided with a low-power light source detection module 22, a high-power light source detection module 21, an optical path switching module 23, a CCD image sensor 24 and a target adjustment module 25 .

[0048] refer to figure 1 , the low power source detection module 22 includes a low power ring light source 223 fixed on the probe detection box 26, a low power point light source 221, a low power beam splitter 222 and a low power lens 224, a low power ring light source 223 and a low power point light source 221 are respectively installed on the outer sides of the mutually perpendicular side walls, and the low-magnification ring light source 223 faces directly upward. The center of the low-magnification ring light source 223 has a low-magnification point light source 221 emission hole, and the low-magnifi...

Embodiment 2

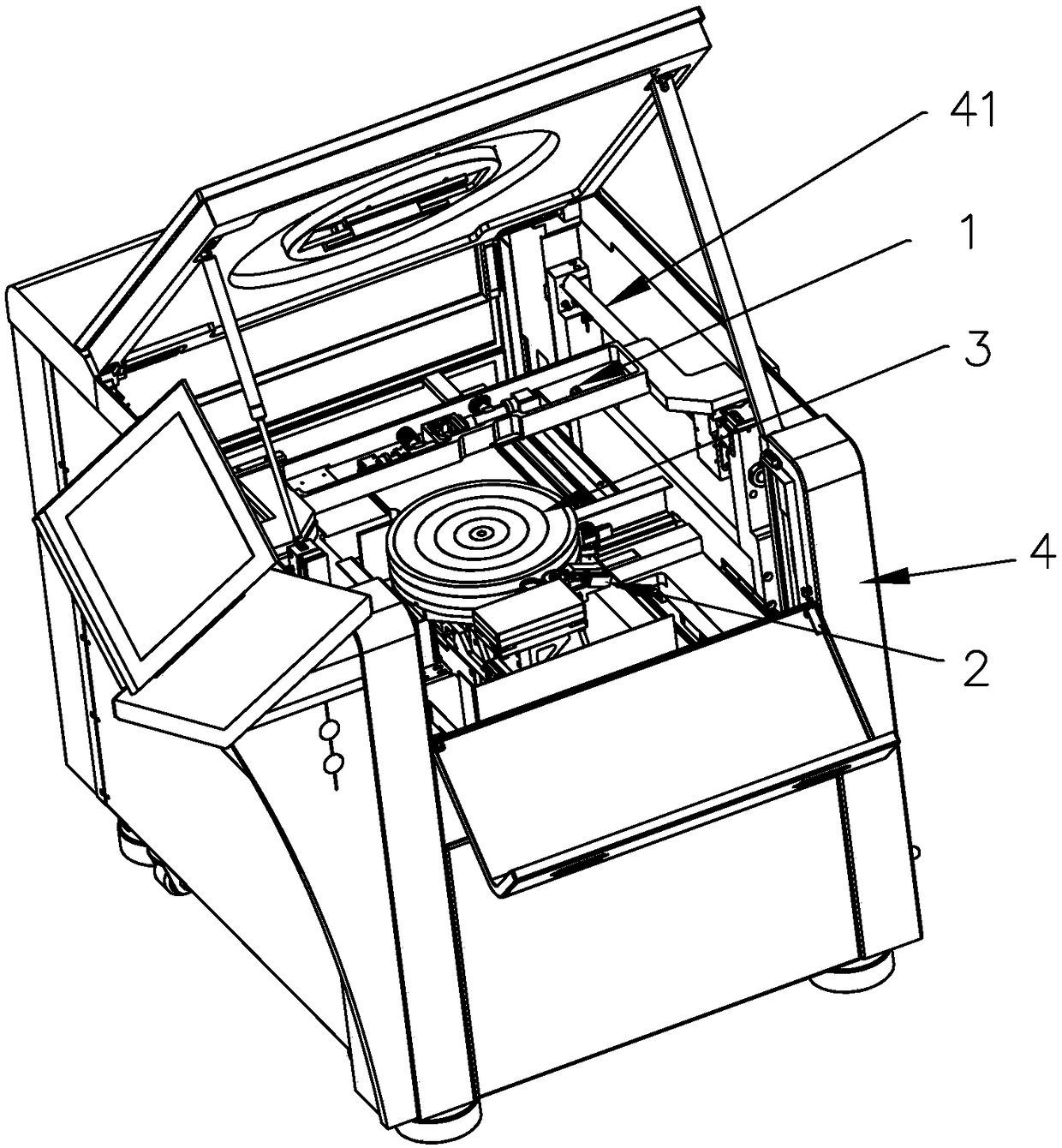

[0056] Embodiment 2: a kind of automatic probe detection platform, as image 3 As shown, it includes the chip positioning module 1 and the probe positioning module 2 in Embodiment 1, which are used for the probe positioning of the probe detection station. The probe detection station includes a body 4, a workbench 3 and a machine cover, and the machine cover A probe card is installed on it. The workbench 3 moves in the three directions of X, Y and Z in the box. Horizontal sliding rods 41 are fixed on the inner walls of both sides of the box, and the horizontal sliding rods 41 are slidably connected to the chip positioning module 1 .

[0057] refer to Figure 4 and Figure 5 The chip positioning module 1 includes a high power mirror module 12 , a low power mirror module 11 , a chip optical path module 13 and a height detection module 14 . The high power mirror module 12 includes a chip CCD sensor, a high power mirror and a high power light source. The high power mirror leads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com