Shaft reflective pulse laser beam combiner and pulse beam combiner laser system

A technology of laser beam combiner and pulse laser, which is applied in the field of laser, can solve the problems that it is difficult to adapt to the impact of high-power laser beam quality, and achieve the effects of easy engineering implementation, improved laser tolerance, and increased power and repetition frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

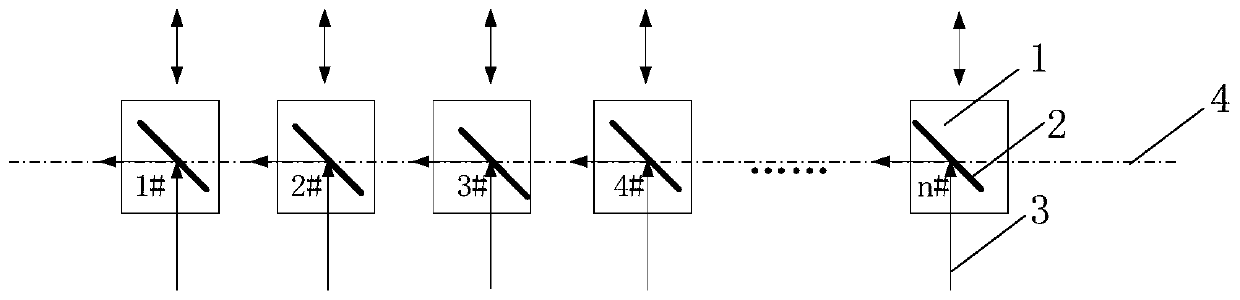

[0038] Such as figure 1 , figure 2 with image 3 As shown, the principle idea of pulse combining in the present invention is: on the same output optical path 4, n reflectors 2 are obliquely arranged, and each reflector 2 is arranged on the displacement device 1, and can make the reflector 2 along the In the mirror shifting direction 3, move out of the beam combining optical path and then move back to the beam combining optical path, the beam combining optical path is the output optical path 4; the shifting device 1 can be an integral mechanism or a split mechanism, which can realize 2 mirrors each independent movement in and out.

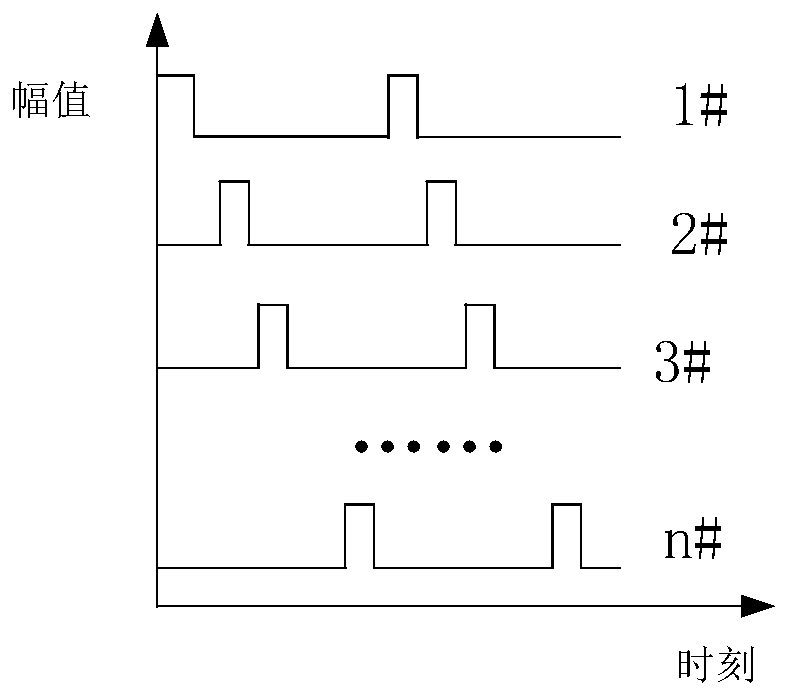

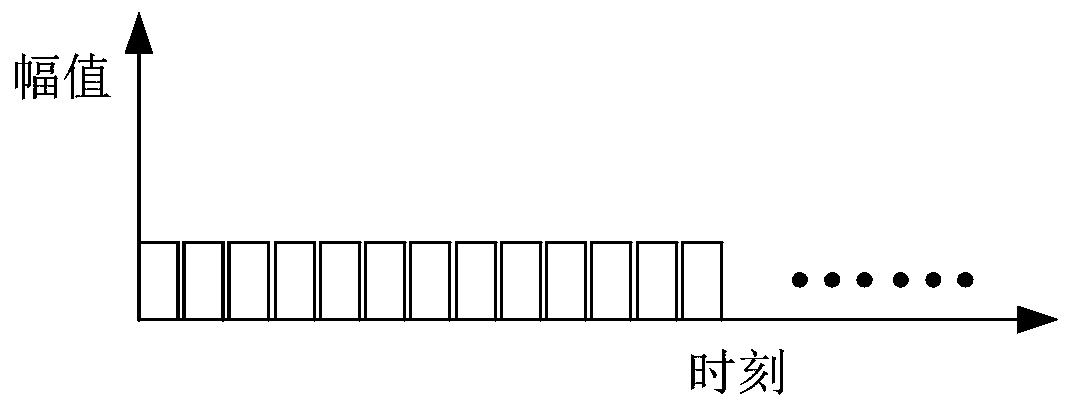

[0039] Each reflector 2 corresponds to the incident laser beam 3, where the laser is a pulsed laser output at a repeated frequency, and the light output timing of each laser is as follows figure 2 As shown,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com