Electrical assembly

A technology of components and electrical appliances, applied in relays, electrical components, electromagnetic relays, etc., can solve the problems of high cost, high cost, affecting the normal use of products, etc., and achieve the effect of low cost, simple structure and saving contact cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

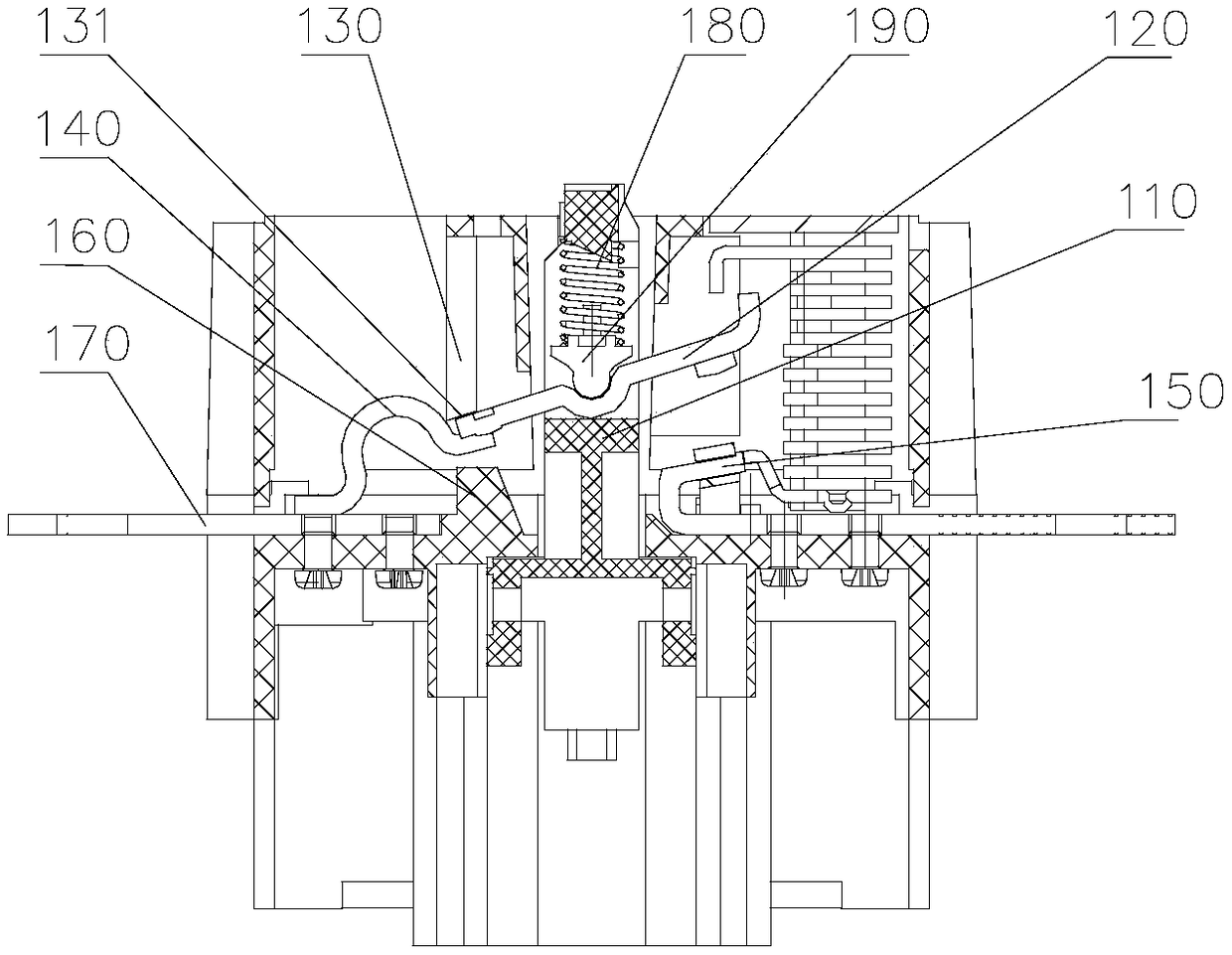

[0026] Such as figure 1 As shown, this embodiment discloses an electrical component. In this embodiment, the electrical component can be used as a contactor. The electrical assembly includes a housing, a contact assembly disposed in the housing, and a support structure 160 relatively fixed to the housing. Wherein, the contact assembly includes a static contact 150, a moving contact 120, and a contact supporting part for supporting the moving contact, and one end of the moving contact 120 can be in contact with or separated from the support structure 160, The other end of the movable contact 120 can be in contact with or separated from the static contact 150 . In this embodiment, the support structure 160 can be in contact with or separated from the movable contact 120. After the movable contact 120 is in contact with the static contact 150, the movable contact 120 Driven by the supporting part, it moves for a certain distance and contacts with the supporting structure 160 ....

Embodiment 2

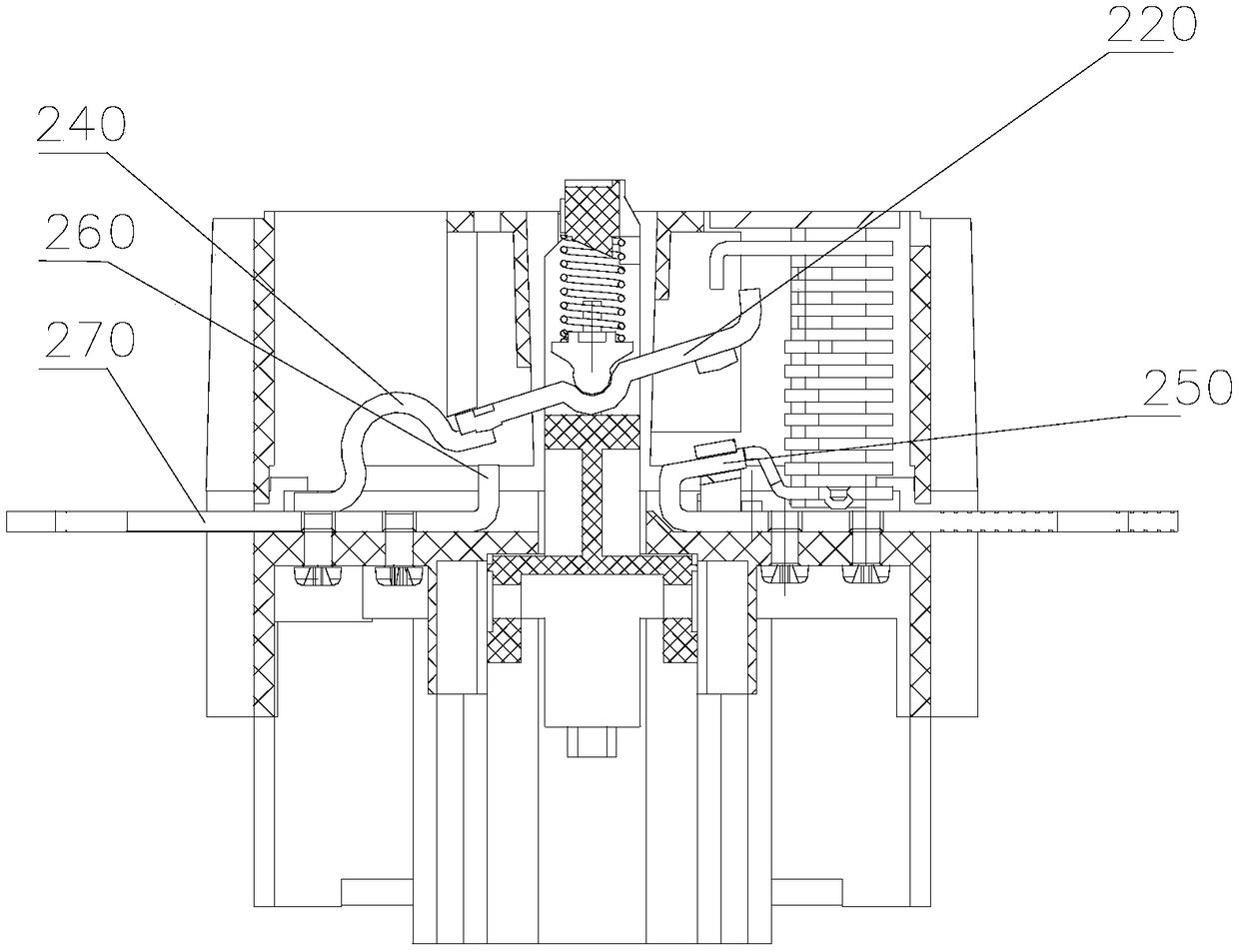

[0046] like figure 2 As shown, this embodiment discloses another electrical component. The electrical component in this embodiment can be used as a contactor. In this embodiment, the electrical component includes a support structure 260 corresponding to the position-limiting structure. When the movable contact 220 moves towards the static contact 250 under the action of the contact supporting part, the support structure 260 can support one end of the movable contact 220 so that the movable contact 220 is supported by the contact. Closed with the static contact 250 under the action of the part.

[0047] In this embodiment, in order to realize the electrical connection between the moving contact 220 and the external circuit, the electrical component further includes a conductive terminal block 270 electrically connected to the external circuit, and the moving contact 220 can be connected to the conductive wiring through a flexible connection wire 240 The socket 270 is electr...

Embodiment 3

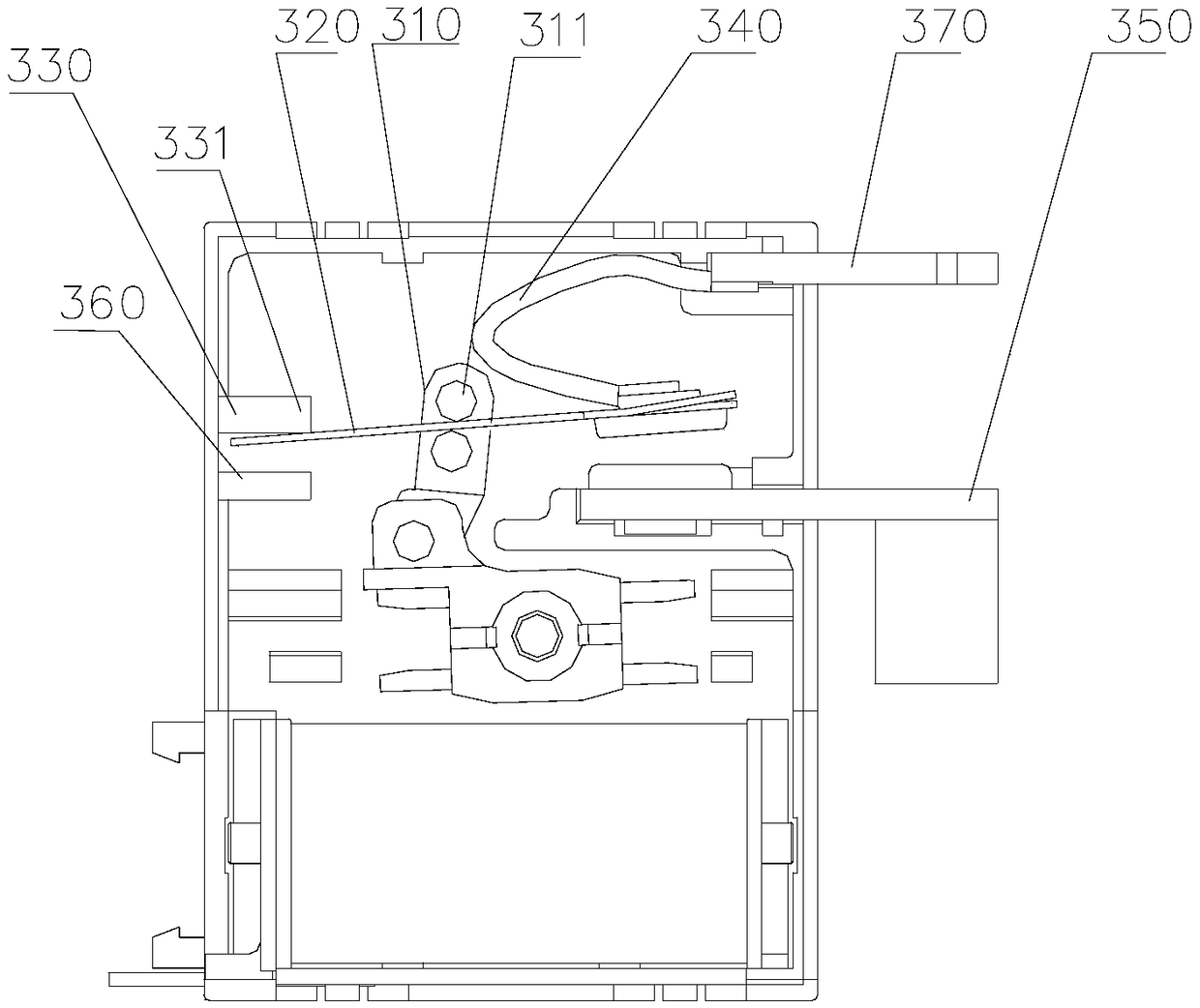

[0051] like image 3As shown, this embodiment discloses another electrical component. The electrical components in this embodiment can be used as electromagnetic relays, specifically, as magnetic latching relays. The electrical assembly in this embodiment includes a contact assembly and a supporting structure 360 . The contact assembly includes a static contact 350 , a moving contact 320 and a contact supporting part 310 supporting the moving contact 320 . The contact supporting part 310 can move under the force of the electromagnetic assembly and drive the moving contact 320 to move, the supporting structure 360 can contact or separate from the moving contact 320, and the moving contact 320 After being in contact with the static contact 350 , the moving contact 320 is driven by the contact supporting part 310 to move for a certain distance and then contact with the support structure 360 . The electrical component also includes a limiting structure 330 corresponding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com