A flexible graphite bipolar plate of fuel cell mass production system and a production method thereof

A flexible graphite, fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as increased labor costs, inability to effectively guarantee product quality consistency, and inability to achieve large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

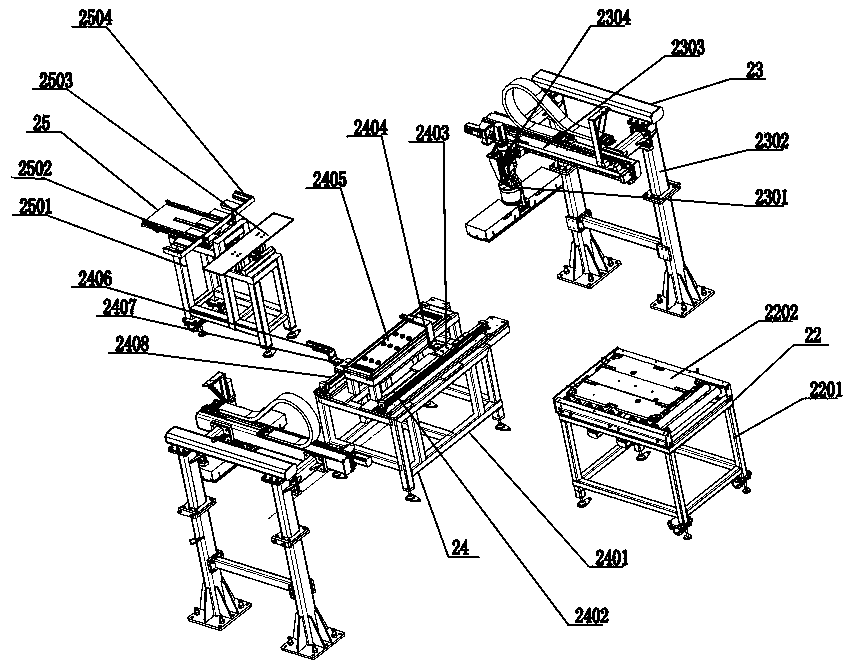

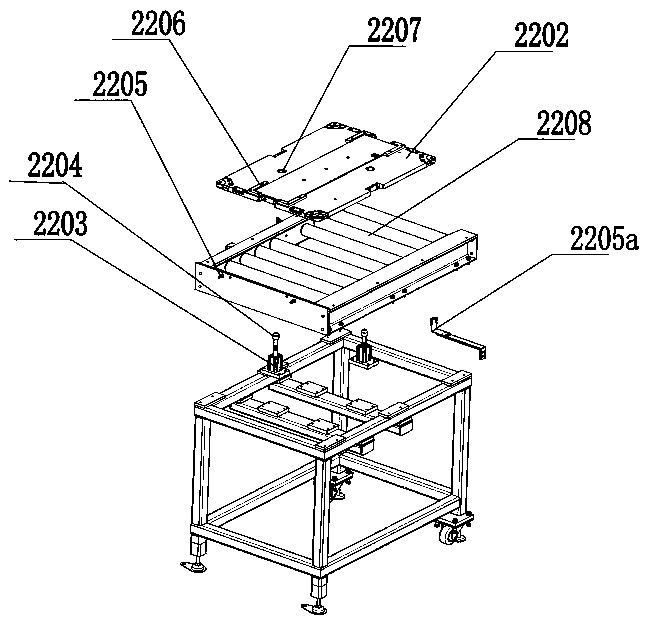

[0040] The present invention will be further described below in conjunction with the accompanying drawings of the description.

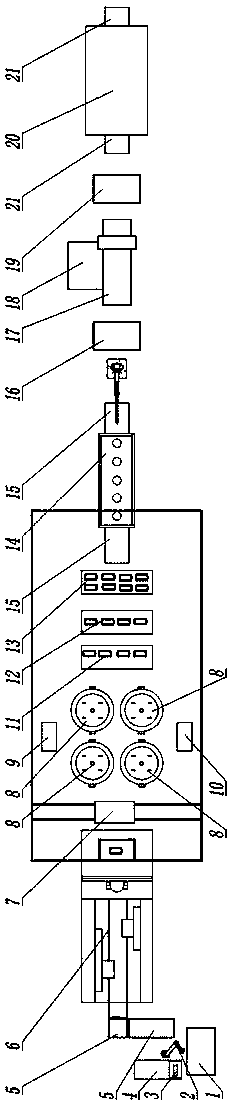

[0041] As shown in the figure, the continuous production system of flexible graphite bipolar plates for hydrogen fuel cells is composed of a molding device, a cleaning basket loading device, a vacuum impregnation device, and a surface treatment device that are connected together, and also includes a leveling device that is connected in sequence , gluing device, pressure bonding device, high temperature curing device, surface treatment device and leveling device are connected together.

[0042] Adopt the production method of above-mentioned continuous production system, comprise the following steps:

[0043] 1) The low-density expanded graphite plate is sequentially processed through four steps of molding forming by molding device, cleaning basket by cleaning basket loading device, vacuum impregnation by vacuum impregnation device, and surface treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com