Winding device

A winding device and needle rolling technology, which can be used in battery assembly machines, sustainable manufacturing/processing, electrochemical generators, etc., can solve problems such as inability to apply well, and achieve improved glue application efficiency, simple structure, and operation and maintenance. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention will be further elaborated below with reference to the accompanying drawings of the present specification.

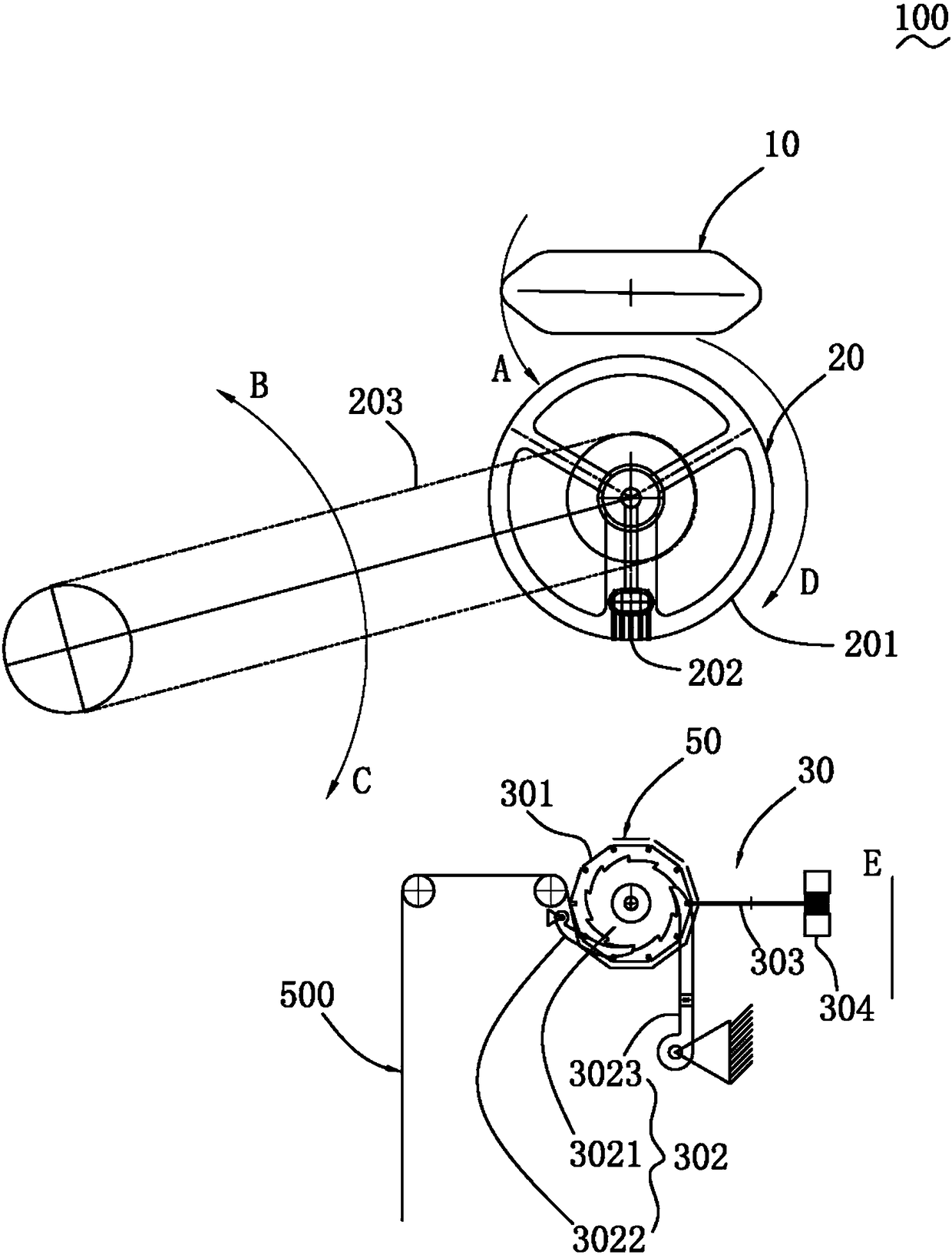

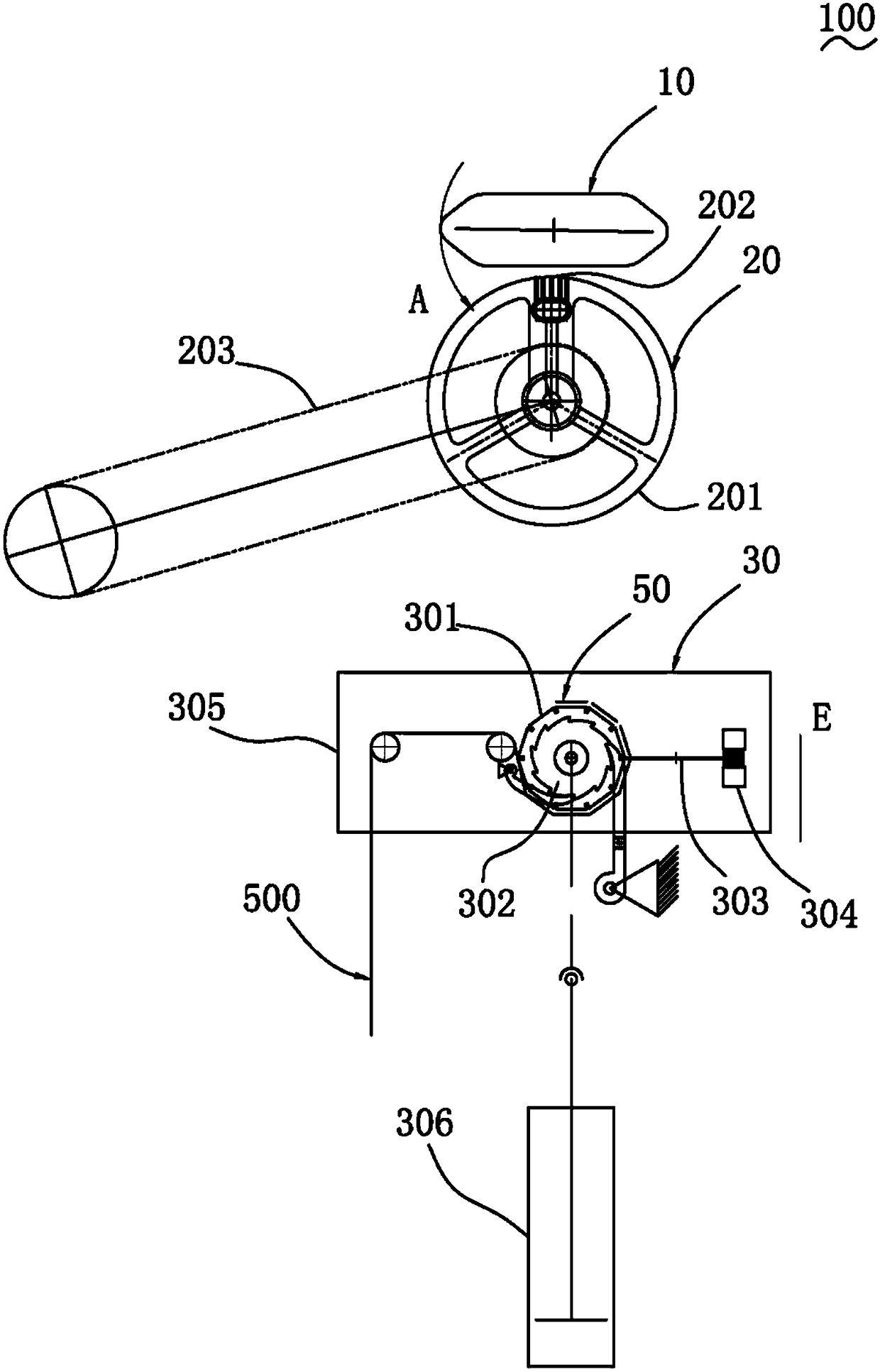

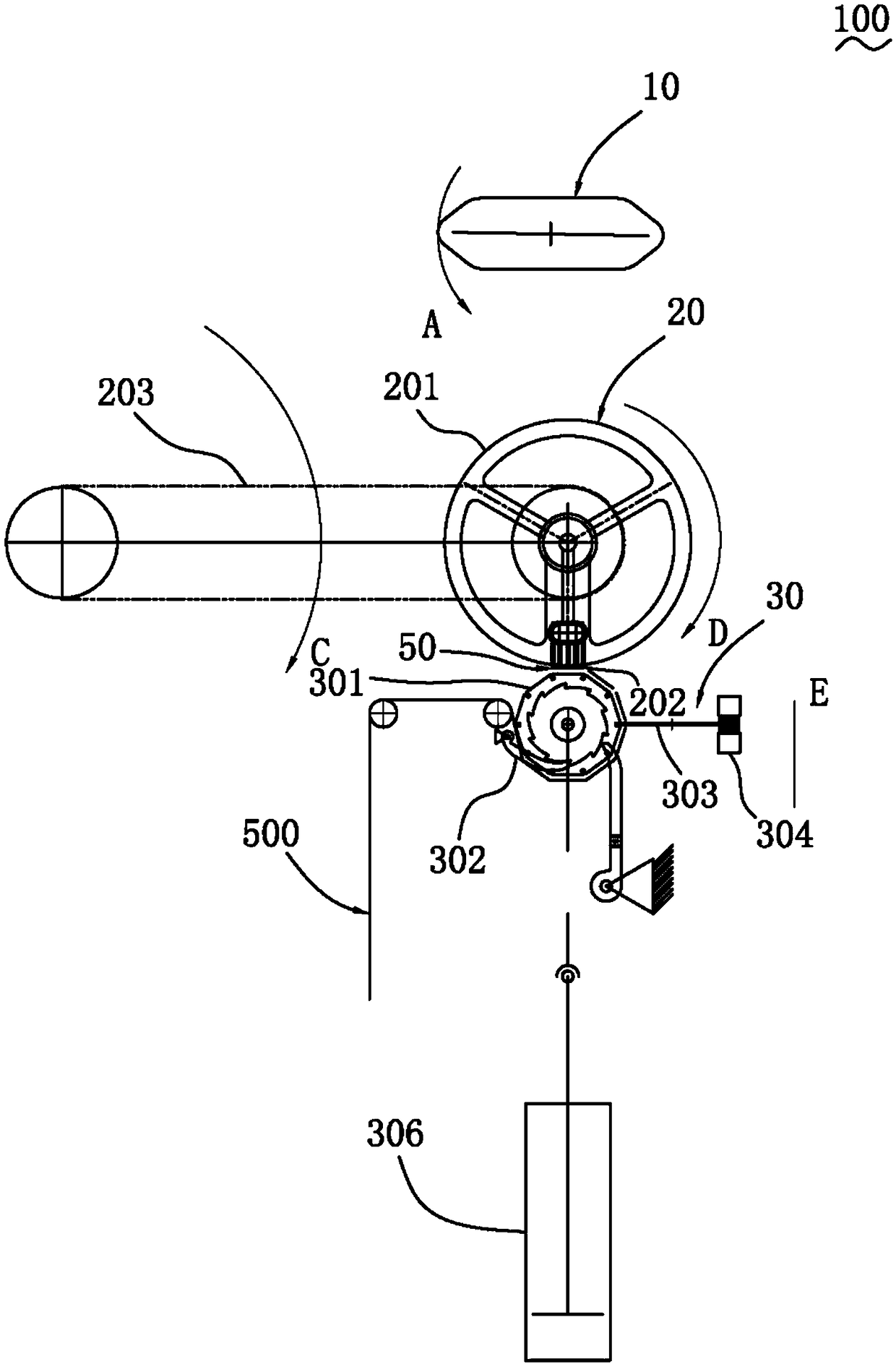

[0013] see figure 1 , figure 1 It is a structural representation of the winding device of the present invention. The present invention proposes a winding device 100, the winding device 100 adopts the way of feeding the adhesive paper 500 horizontally to realize the glue application, that is, a single adhesive paper 50 is rectangular and has a set length and width. The cutting of a single adhesive tape 50 extends along the width direction of the adhesive tape 500 . The winding device 100 includes: a winding needle 10, which is used to wind the base material (such as a battery cell of a lithium battery); 10; and the glue preparation unit 30, which is used to pull the adhesive tape 500, and cut into individual adhesive tapes 50 in turn, for the gluing unit 20 to pick up. In this embodiment, the set position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com