A semi-open, compact, integral torque motor

A torque motor, semi-opening technology, applied in the field of permanent magnet DC torque motor, can solve the problems of unsuitable lightweight high-precision drive system, large volume, etc., to achieve the elimination of axial reciprocating gap, high torque density, easy disassembly and assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

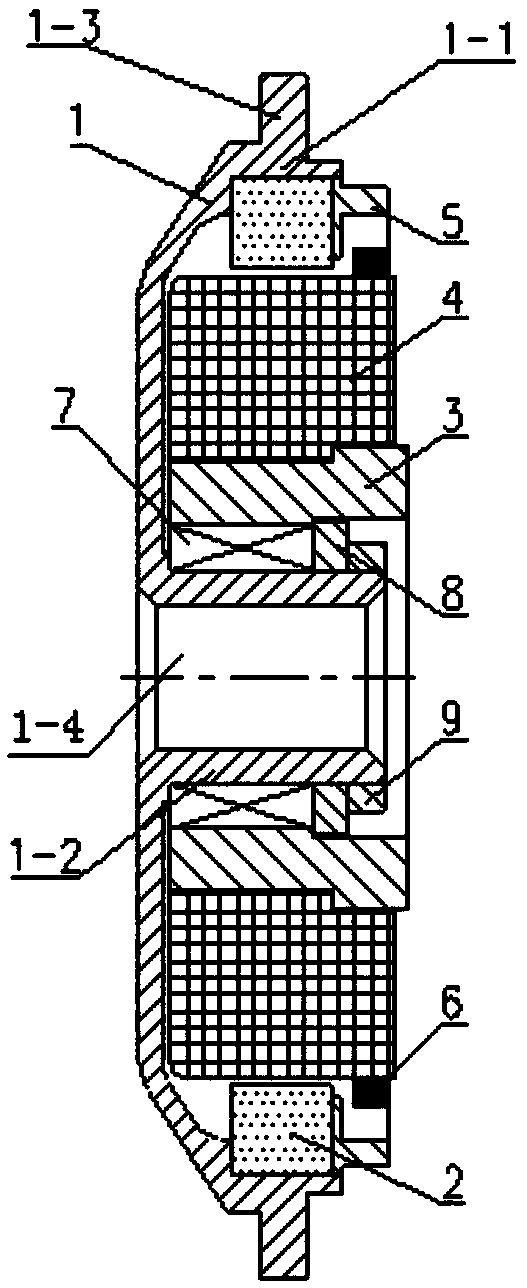

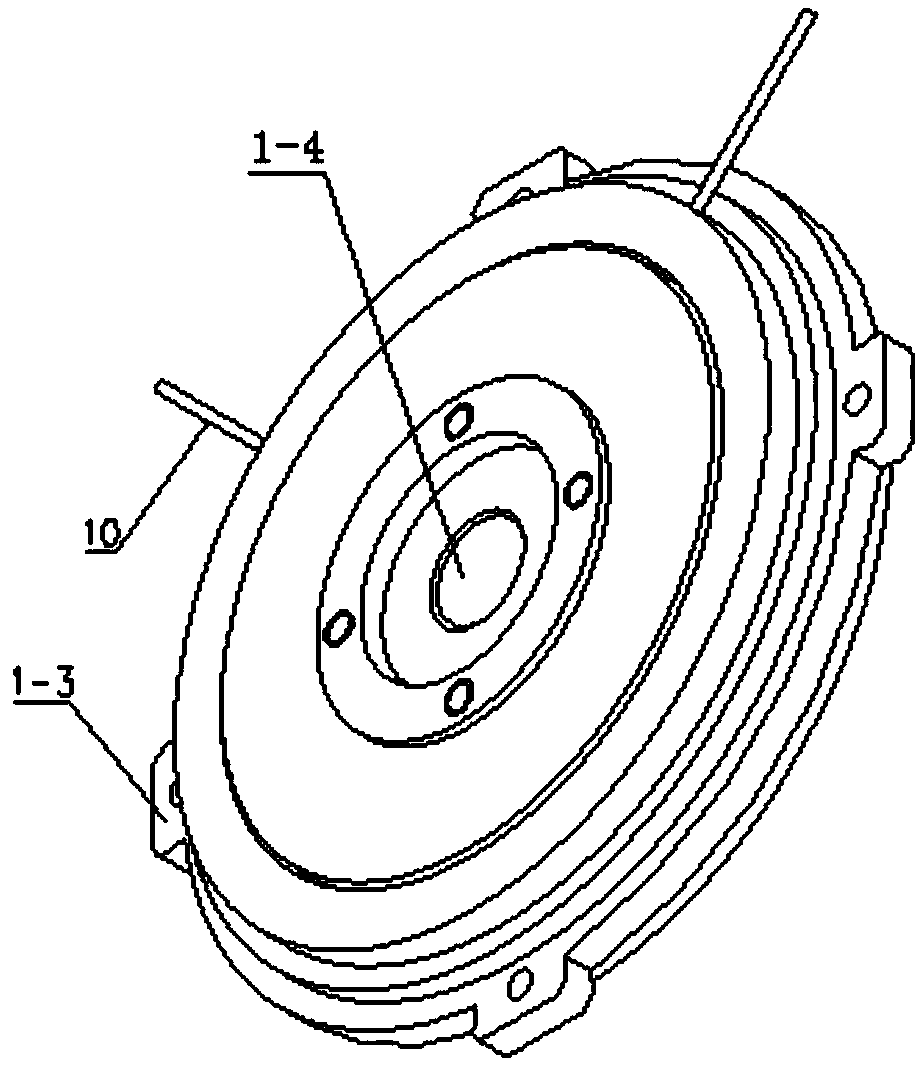

[0026] A semi-open compact self-contained torque motor. The motor is a self-contained structure, which includes a casing assembly 1, a magnetic steel 2, a shaft sleeve 3, an armature winding 4, a brush holder 5, and a brush 6. Bearing 7, inner lock nut 8, outer lock nut 9 and lead wire 10. The casing assembly is a semi-open structure with one side closed and one side open. The casing assembly has an inner cavity, bearings, bushings, armature windings, inner lock nuts, outer lock nuts, magnetic steel, brush holders and brushes. located in this lumen.

[0027] The casing assembly 1 includes a casing outer ring 1-1, a casing shaft 1-2 and a casing flange 1-3, and there are multiple casing flanges. In this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com