Furrow three-dimensional planting technique for improving light energy utilization efficiency of summer corn

A technology of three-dimensional planting and summer corn, applied in the fields of application, grain cultivation, fertilization methods, etc., can solve the problems limited to ridge farming or furrow planting, and achieve the effects of easy technology mastery, easy production and application, and enhanced photosynthetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

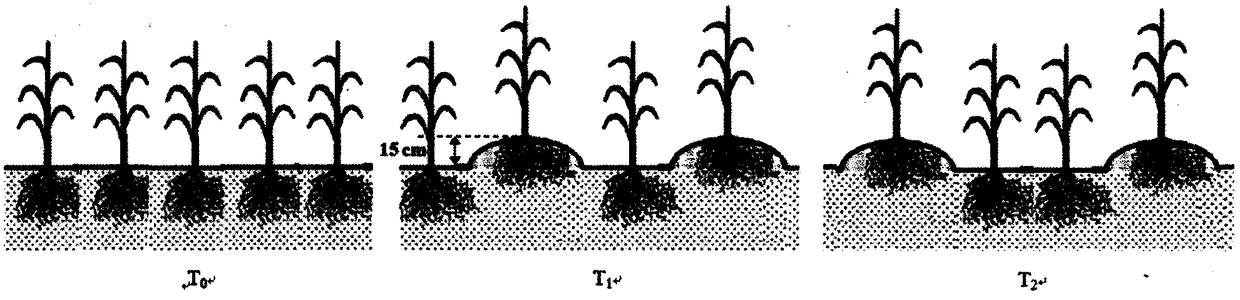

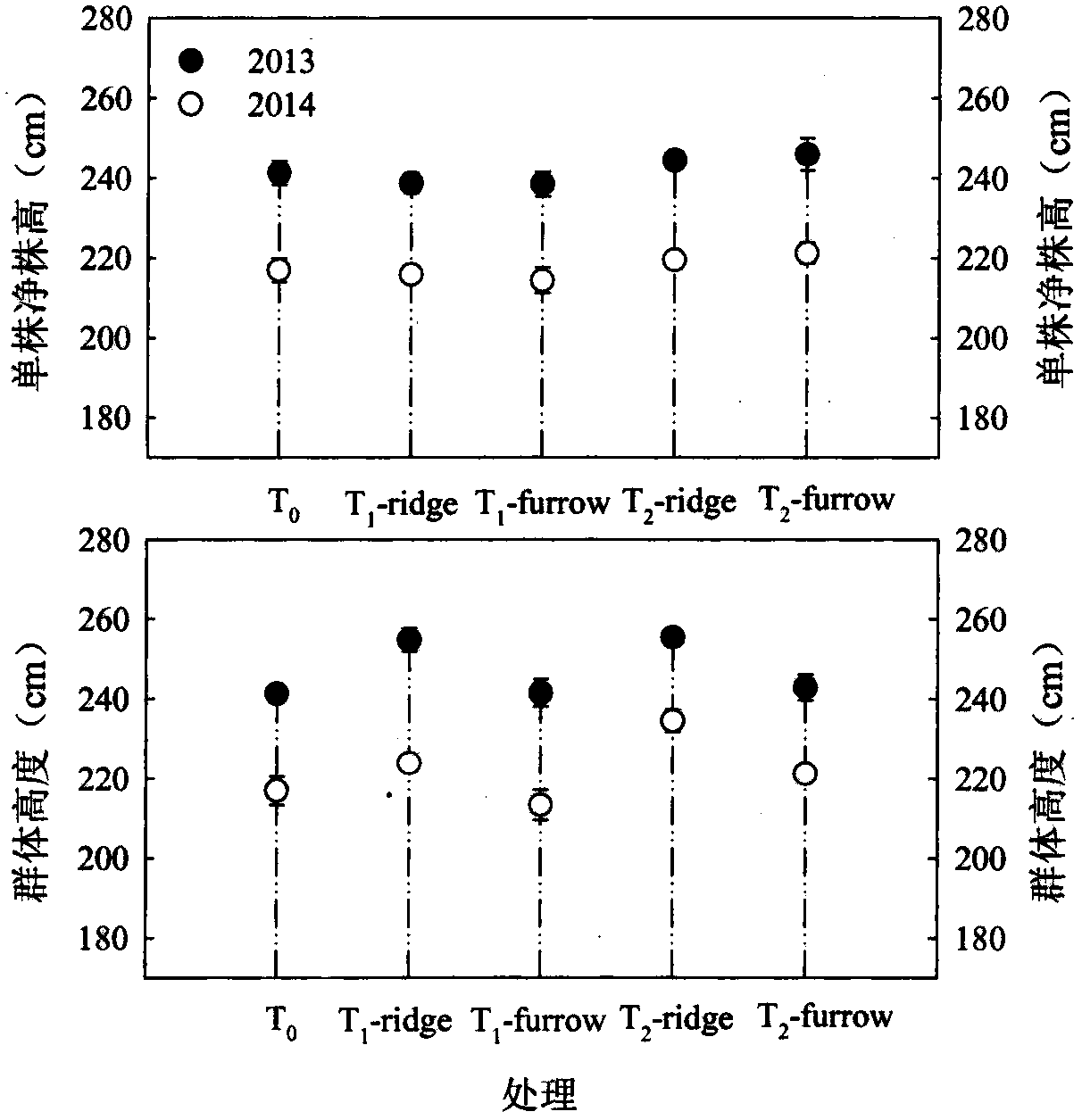

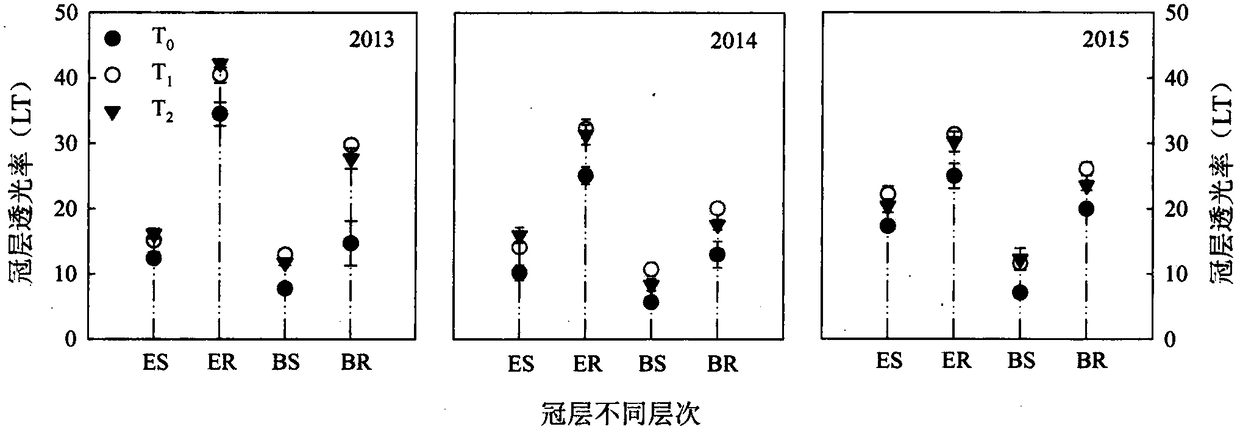

[0034] A ridge and furrow three-dimensional planting technology for improving the light energy utilization efficiency of summer maize, specifically comprising the following steps: 1) constructing a ridge width of 60 cm, a ridge height of 15 cm, and a ridge width of 60 cm on the farmland ground through mechanical or manual operations. 2) Ditch and fertilize at the junction of furrows and furrows. The type and amount of fertilization are pure nitrogen 112.5kg hm -2 ,P 2 o 5 120kg hm -2 、K 2 O96kg hm -2 , the fertilization depth is 8-10cm; 3) Plant summer corn on the ridge and in the ditch respectively: plant a row of corn at the middle of the ridge and the middle of the ditch, with a row spacing of 60cm and a plant spacing of 24-25cm; , topdressing nitrogen fertilizer pure nitrogen 112.5kg hm -2 , the fertilization depth is 5-8cm; 5) Based on the micro-topography of the ground furrows and ridges, the difference in the vertical height of the individual in the maize populati...

Embodiment 2

[0036] A ridge and furrow three-dimensional planting technology for improving the light energy utilization efficiency of summer corn, which specifically includes the following steps: 1) through mechanical or manual operations, construct a micro-furrow pattern with a ridge width of 60 cm, a ridge height of 15 cm, and a ridge width of 120 cm on the farmland ground. 2) Ditch and fertilize respectively at the junction of the ridges and the middle of the ditch. The type and amount of fertilization are pure nitrogen 112.5kg hm -2 ,P 2 o 5 120kghm -2 、K 2 O 96kg hm -2 , and the fertilization depth is 8-10cm; 3) Plant summer corn on the ridge and in the ditch respectively. Plant 1 row in the middle of the ridge, and plant 2 rows of corn at a distance of 30 cm from the bottom of the ridge in the ditch, with a row spacing of 60 cm and a plant spacing of 24 to 25 cm; 4) During the trumpet-mouth stage of corn, topdressing nitrogen fertilizer 112.5 kg hm -2 , the fertilization depth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com