Rapid material squeezing mechanism

A fast, discharge nozzle technology, applied in baking, dough processing, food science, etc., can solve problems such as stagnation of conveying noodles, slow discharge speed of extrusion device, and reduced production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

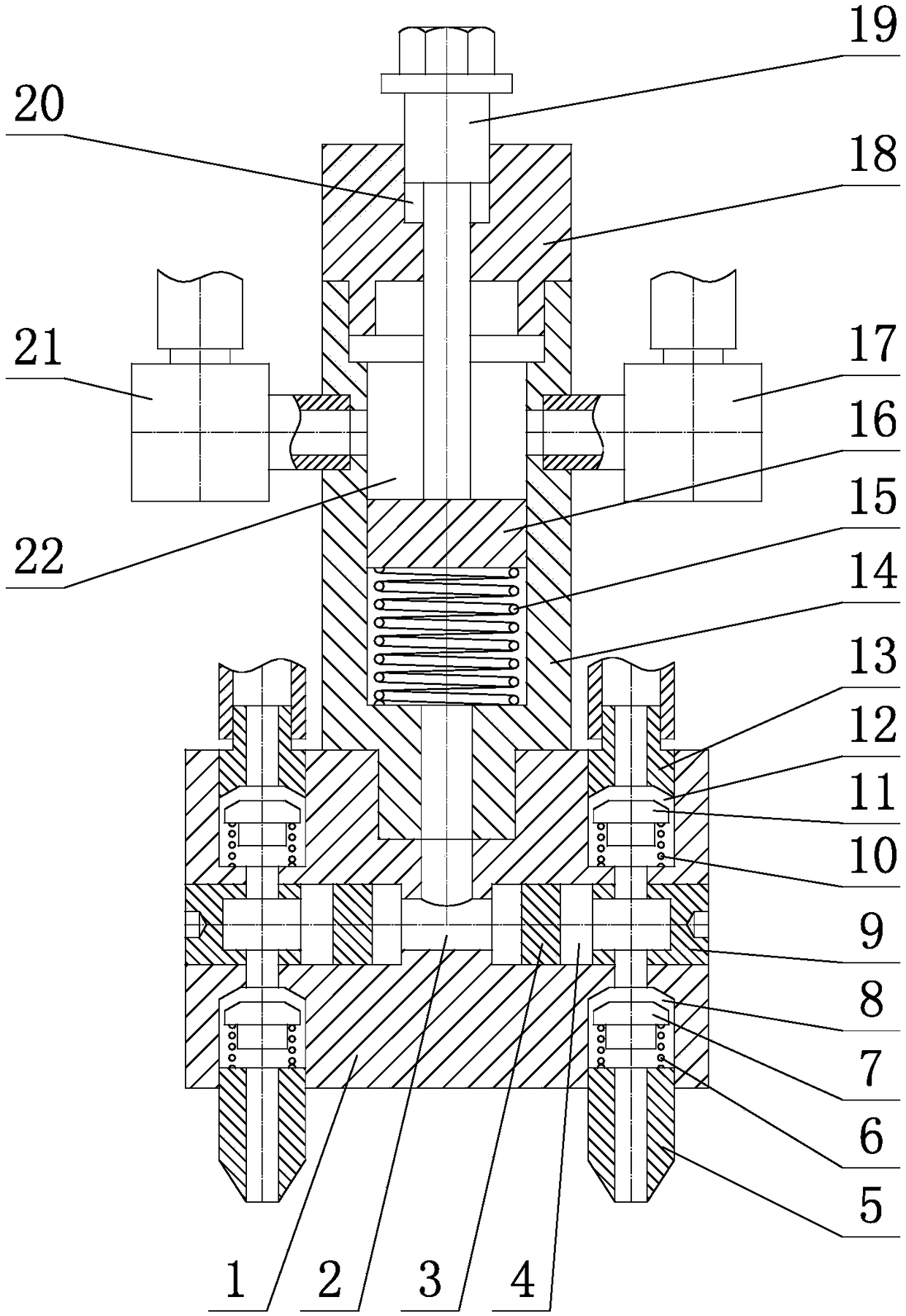

[0015] Such as figure 1 As shown, the rapid extruding mechanism includes a vertically arranged valve body 1, a through hole 2 is opened in the valve body 1, and a first counterbore 4 communicating with the through hole 2 is opened on the side of the valve body 1, Corresponding to the first counterbore 4, the upper end surface of the valve body 1 is provided with a third counterbore 12 connected to the first counterbore 4, and a second cone valve 11 is vertically arranged in the third counterbore 12. A valve seat 13 is provided at the orifice of the counterbore 12, and a second compression spring 10 that lifts the second poppet valve 11 upward is provided at the bottom of the second cone valve 11, corresponding to the third counterbore 12 at the bottom of the valve body 1. The bottom is provided with a second counterbore 8 connected to the first counterbore 4, a discharge nozzle 5 is provided at the orifice of the second counterbore 8, and a first cone valve is vertically provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com