Spiral-guiding carbonated beverage layering device

A technology of spiral diversion and carbonated beverages, which is applied in the direction of food science, etc., can solve the problems of carbon dioxide loss, easy generation of bubbles, and easy diffusion, and achieve the effect of preventing carbon dioxide loss, preventing bubbles, and reducing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

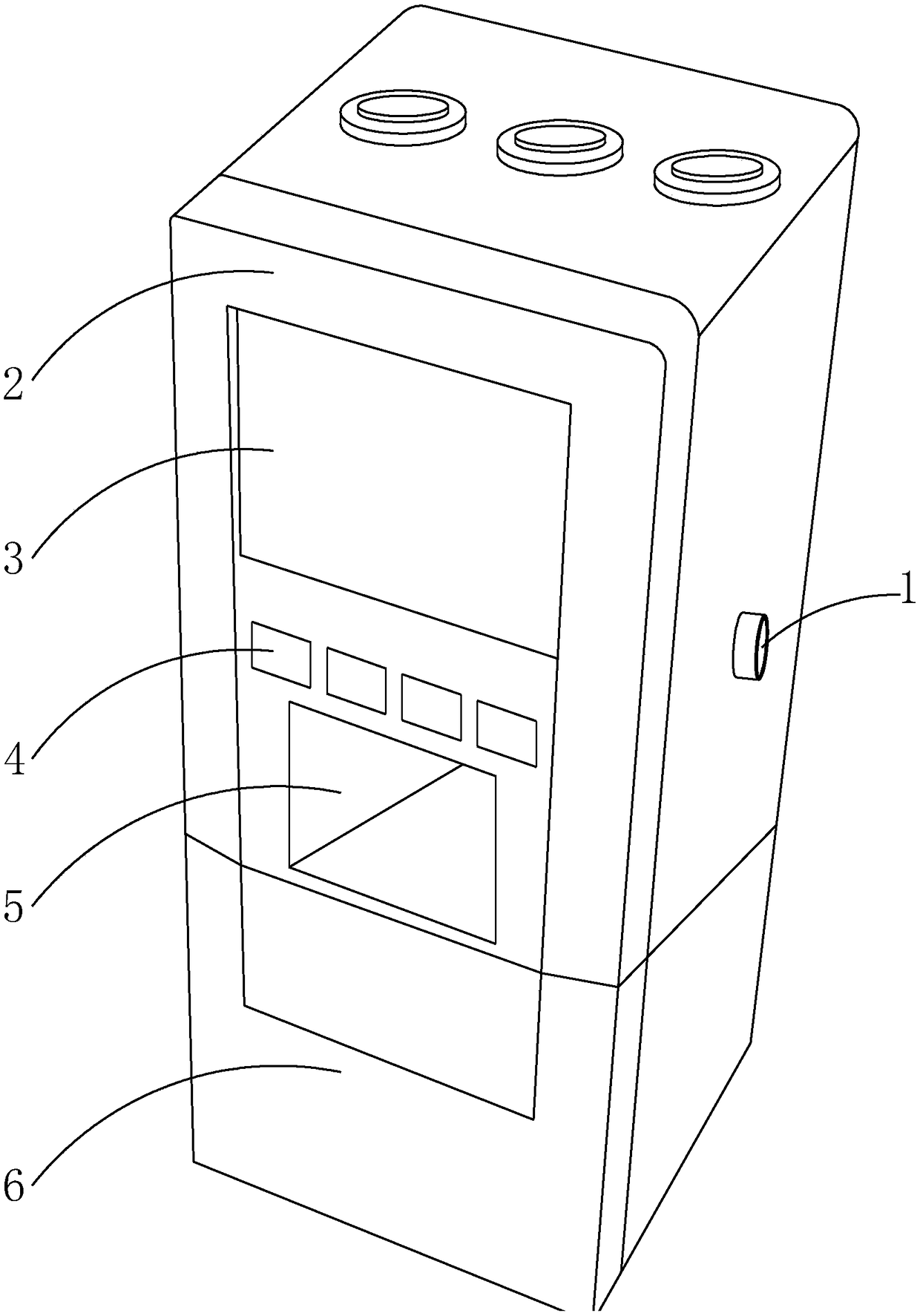

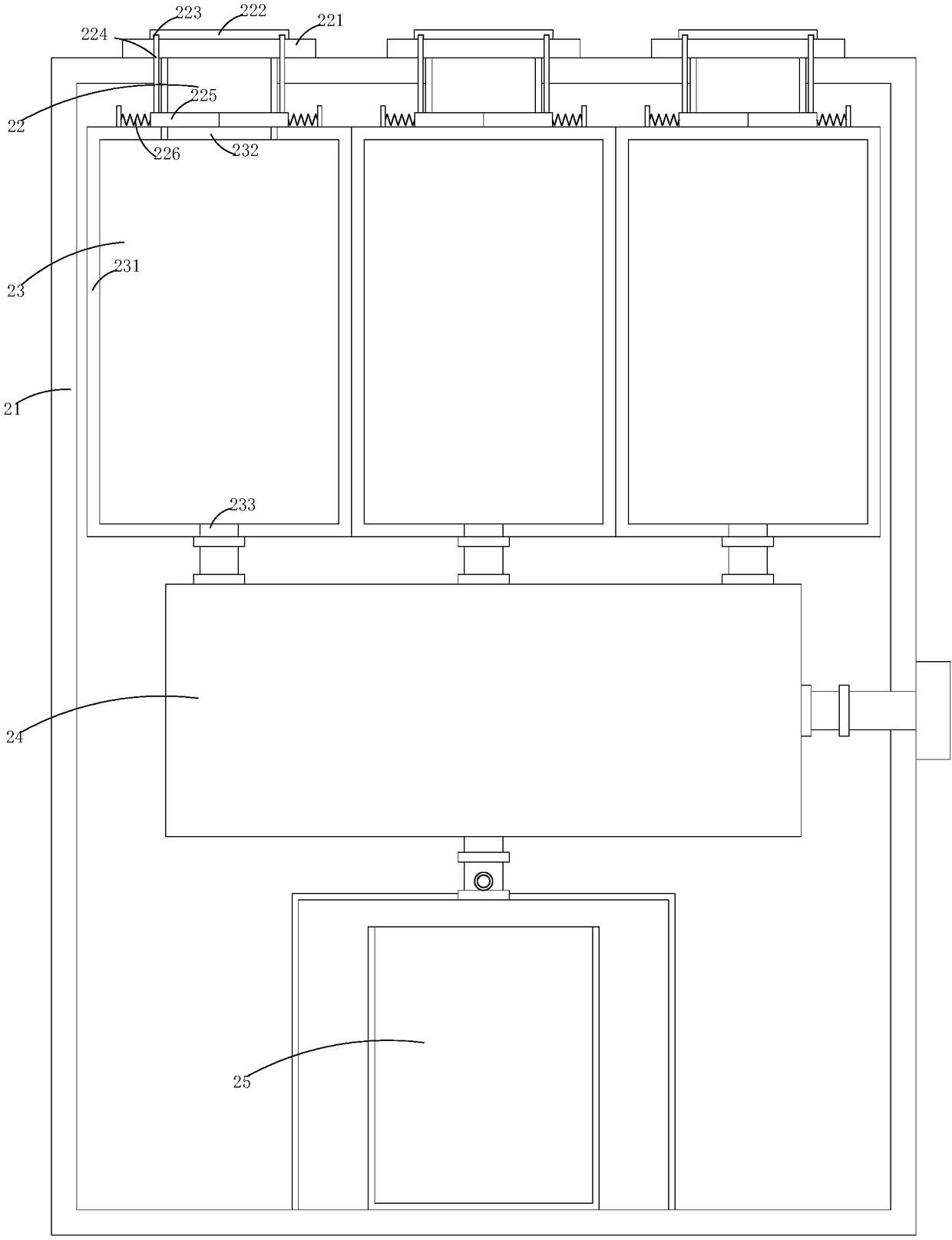

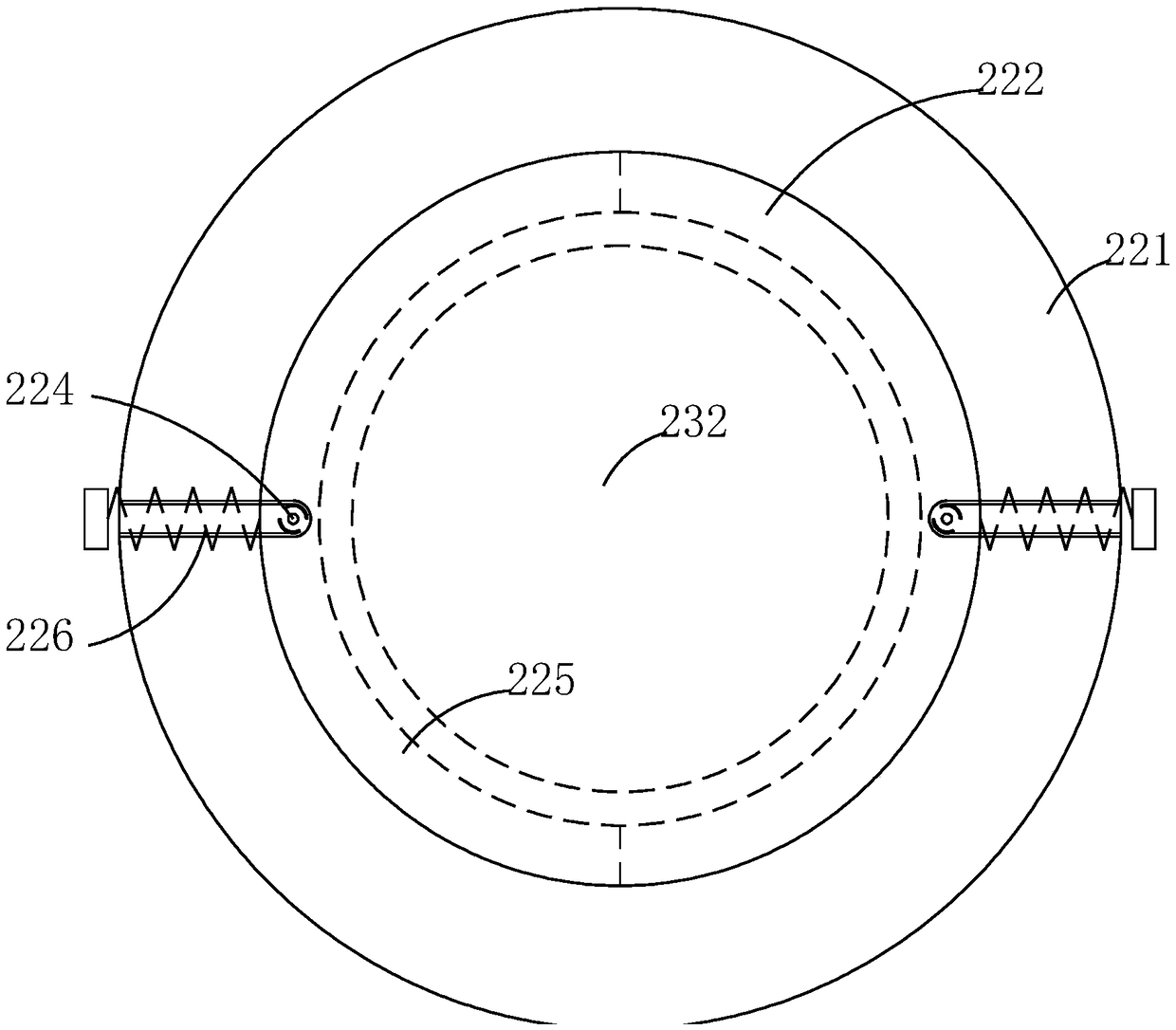

[0020] see Figure 1-Figure 6, a spiral-guided carbonated beverage layering device according to the present invention, comprising a syrup connection port 1, a layering device 2, a window 3, a button 4, a holding port 5, and a base 6, and the syrup connection port 1 is embedded in a layered On the side of the device 2, the front surface of the layered device 2 is provided with a window 3, and there are four buttons 4 in total. The buttons 4 are embedded in the front surface of the layered device 2 and are electrically connected by wires. 5 is located on the layering device 2 and is located directly below the button 4. The top of the base 6 is fixedly connected to the bottom of the layering device 2 and is an integrated structure. The layering device 2 includes a housing 21, a sealing mechanism 22, a storage Mechanism 23, mixing mechanism 24, holding cup 25, the bottom end of the housing 21 is fixedly connected with the top of the base 6 and is an integrated structure, the seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com