Industrial blueberry stock solution rapid squeezing machine

An industrial, blueberry technology, applied in juice extraction, application, food science, etc., can solve the problem of long production time, and achieve the effect of improving the turbulent flow effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

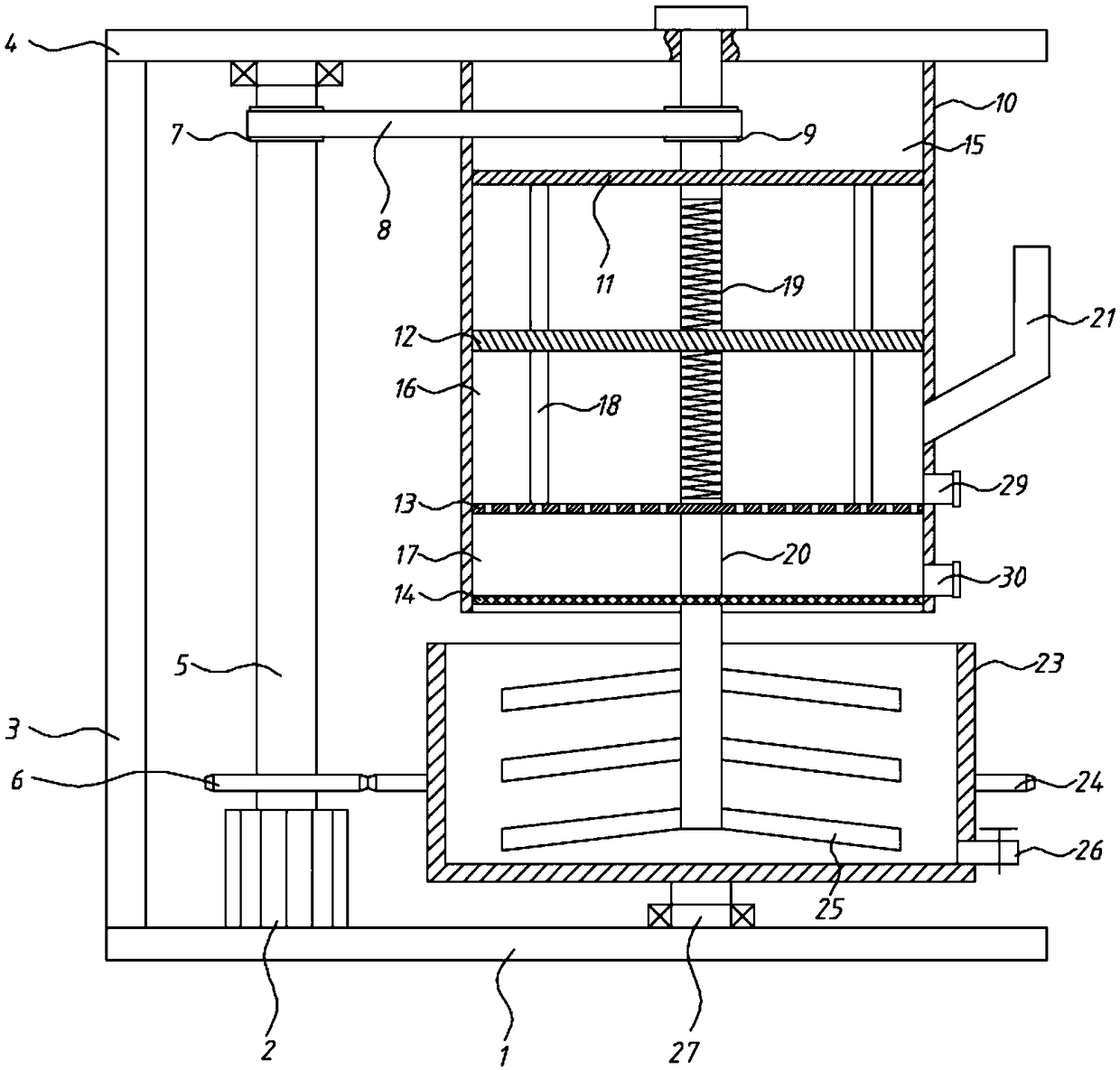

[0038] An industrial rapid extraction machine for blueberry stock solution, comprising a support frame, an upper barrel 10 and a lower barrel 23;

[0039] The support frame includes a base 1, a vertical plate 3 and a top plate 4, the vertical plate 3 is vertically arranged, and the top and bottom ends of the vertical plate 3 are fixedly connected to the left end of the base 1 and the left end of the top plate 4 respectively, forming a C-like structure as a whole; The drive motor 2, the output end of the drive motor 2 protrudes upwards and is connected with the driving shaft 5, and the top of the driving shaft 5 is connected to the top plate 4 in rotation;

[0040] The upper bucket 10 is arranged on the right side of the driving shaft 5, the top of the upper bucket 10 is fixedly connected to the top plate 4, and the bottom of the upper bucket 10 is connected to the outside world; the upper bucket 10 is equipped with a fixed plate 11, a holding plate 13, and a filter screen 14 fr...

Embodiment 2

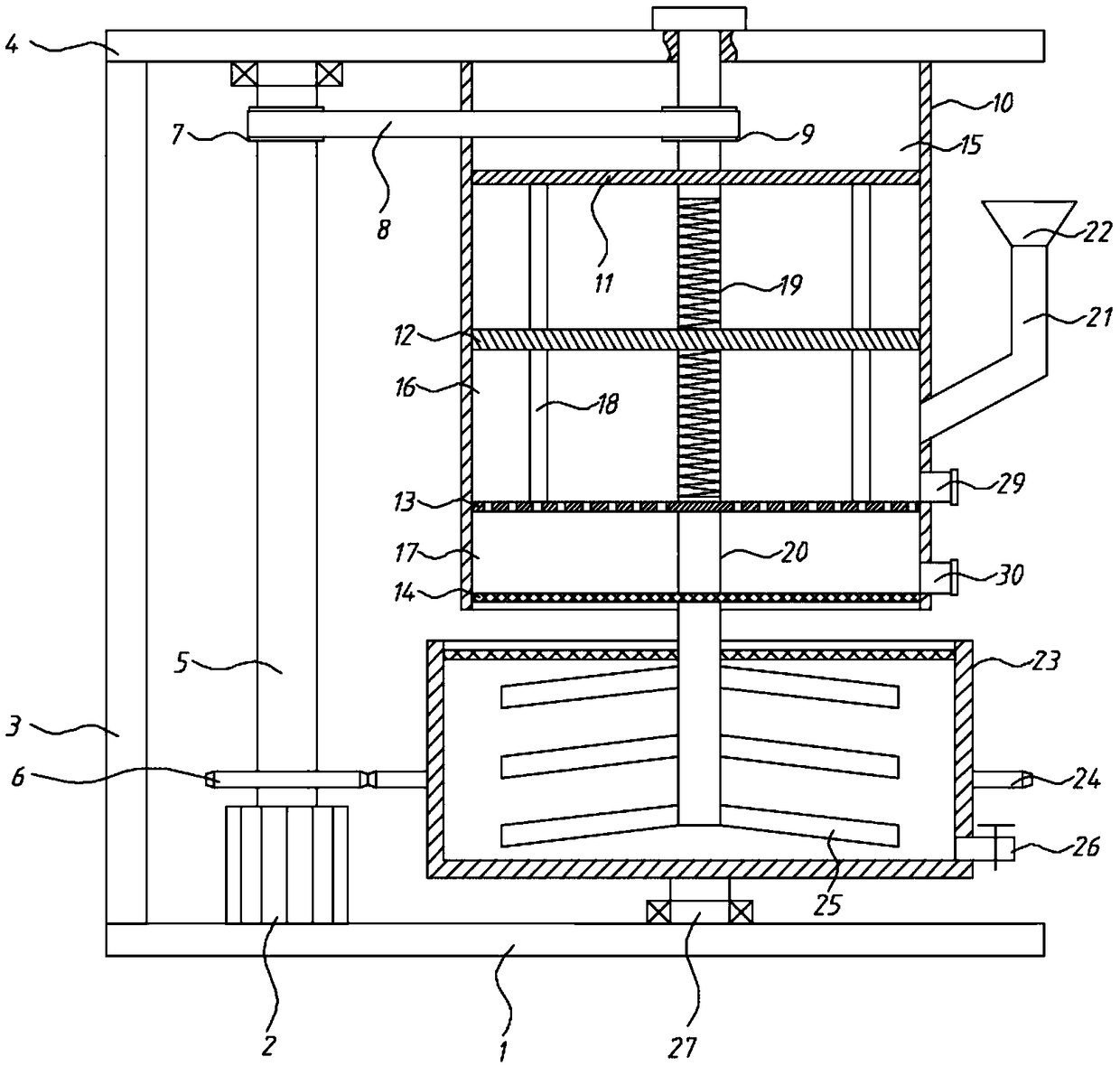

[0045] An industrial rapid extraction machine for blueberry stock solution, comprising a support frame, an upper barrel 10 and a lower barrel 23;

[0046] The support frame includes a base 1, a vertical plate 3 and a top plate 4, the vertical plate 3 is vertically arranged, and the top and bottom ends of the vertical plate 3 are fixedly connected to the left end of the base 1 and the left end of the top plate 4 respectively, forming a C-like structure as a whole; The drive motor 2, the output end of the drive motor 2 protrudes upwards and is connected with the driving shaft 5, and the top of the driving shaft 5 is connected to the top plate 4 in rotation;

[0047] The upper bucket 10 is arranged on the right side of the driving shaft 5, the top of the upper bucket 10 is fixedly connected to the top plate 4, and the bottom of the upper bucket 10 is connected to the outside world; the upper bucket 10 is equipped with a fixed plate 11, a holding plate 13, and a filter screen 14 fr...

Embodiment 3

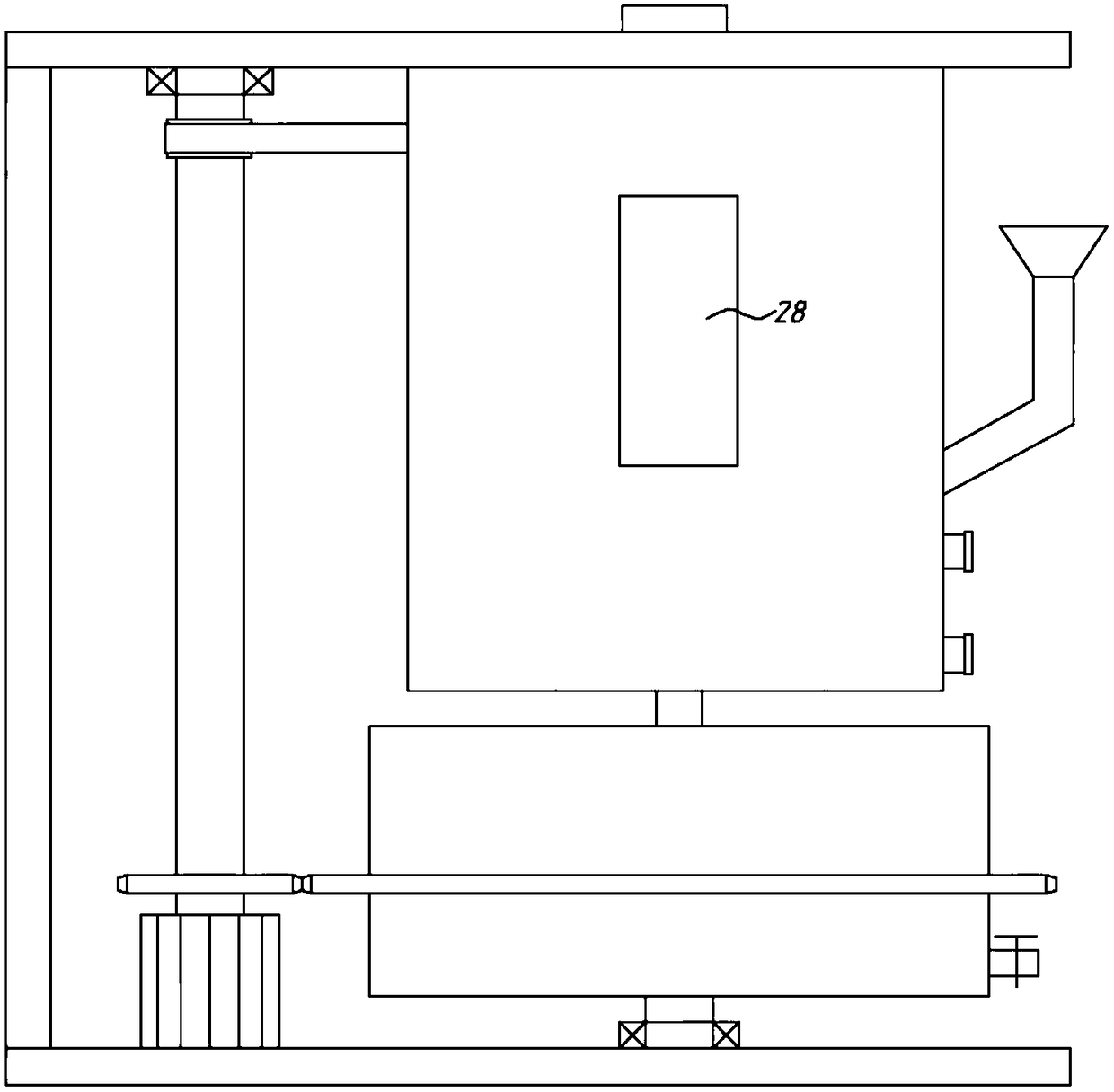

[0052] An industrial rapid extraction machine for blueberry stock solution, comprising a support frame, an upper barrel 10 and a lower barrel 23;

[0053] The support frame includes a base 1, a vertical plate 3 and a top plate 4, the vertical plate 3 is vertically arranged, and the top and bottom ends of the vertical plate 3 are fixedly connected to the left end of the base 1 and the left end of the top plate 4 respectively, forming a C-like structure as a whole; The drive motor 2, the output end of the drive motor 2 protrudes upwards and is connected with the driving shaft 5, and the top of the driving shaft 5 is connected to the top plate 4 in rotation;

[0054] The upper bucket 10 is arranged on the right side of the driving shaft 5, the top of the upper bucket 10 is fixedly connected to the top plate 4, and the bottom of the upper bucket 10 is connected to the outside world; the upper bucket 10 is equipped with a fixed plate 11, a holding plate 13, and a filter screen 14 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com