Vacuum solid-liquid separation and recovery apparatus

A technology of solid-liquid separation and recovery device, applied in the direction of filtration separation, separation method, filtration loop, etc., can solve the problems of polluting the environment and violating the environmental protection law, and achieve the effects of excellent and stable performance, compact structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

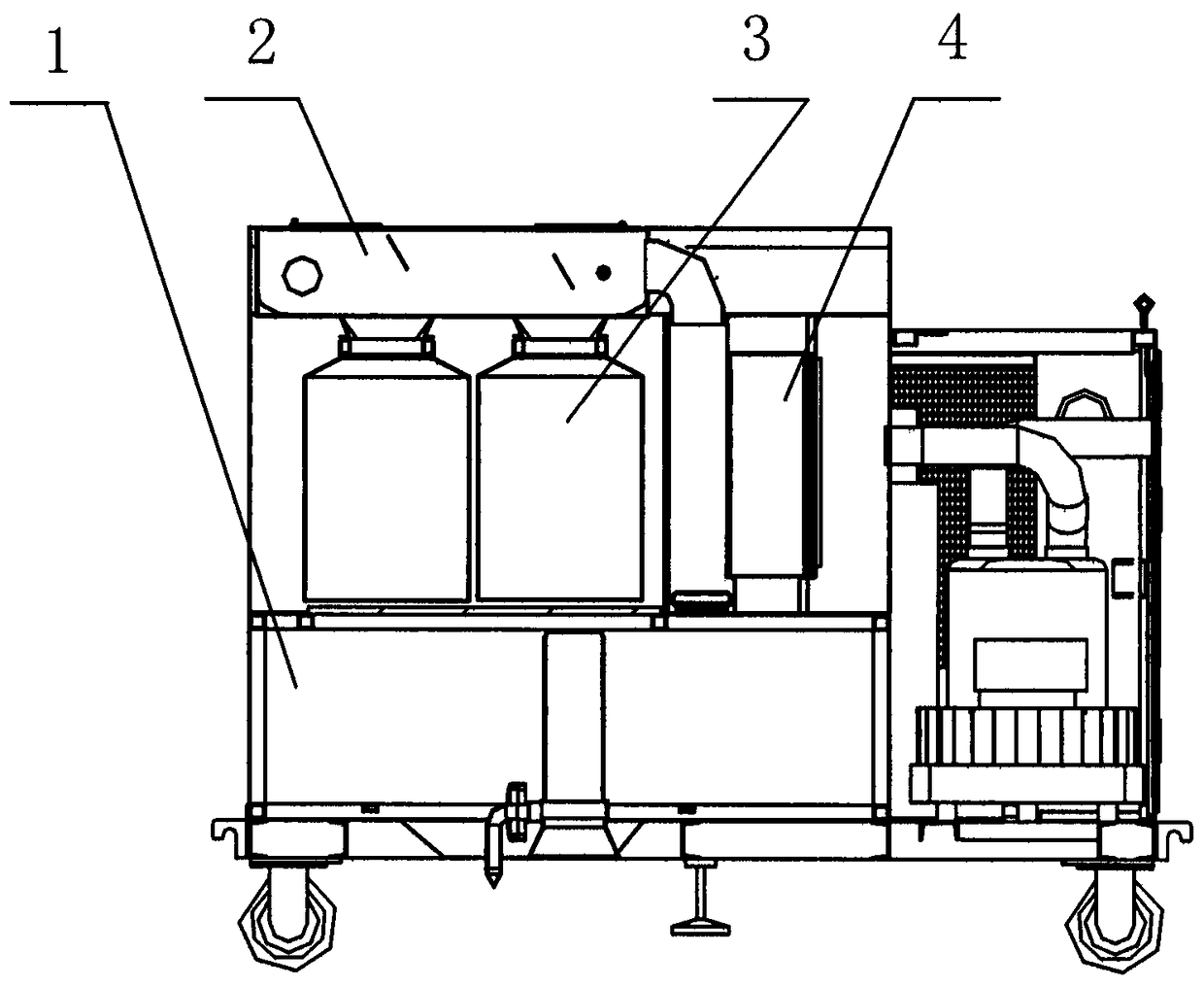

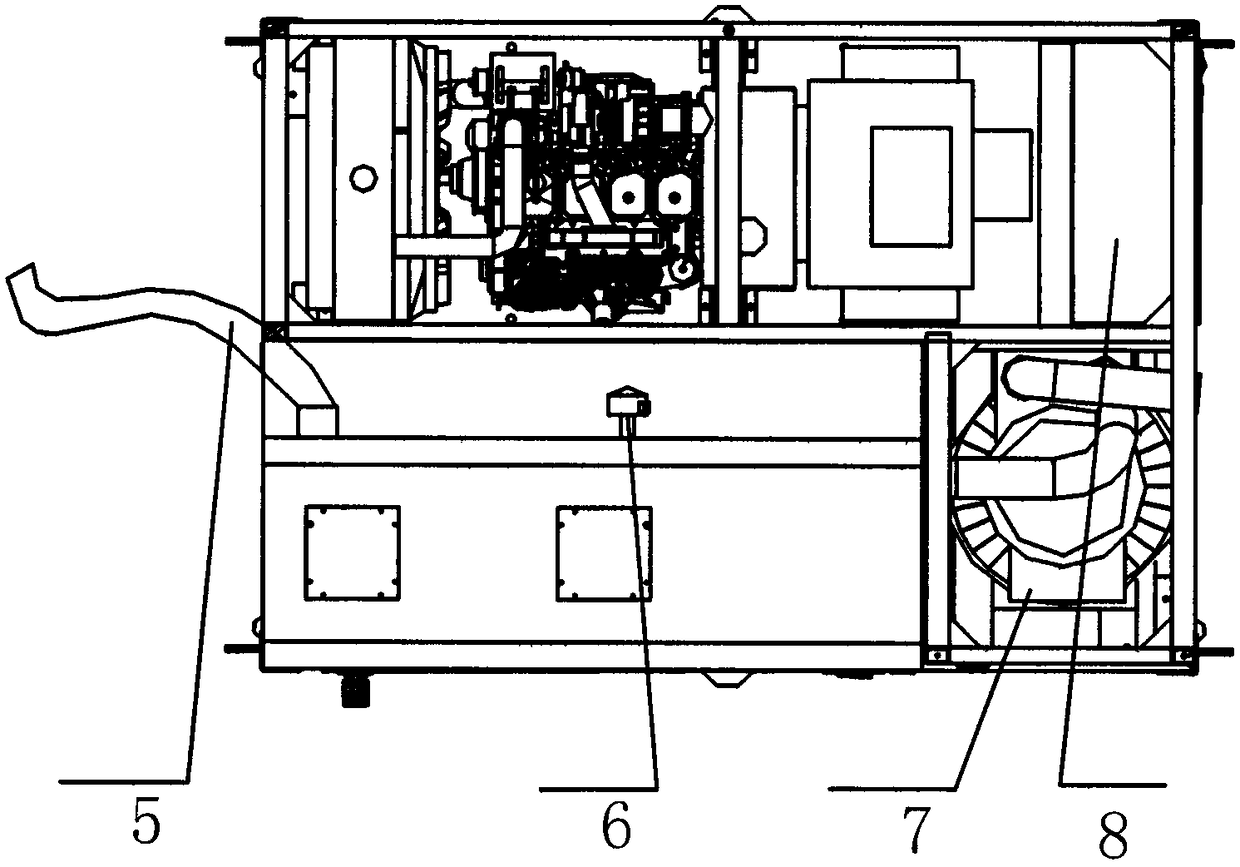

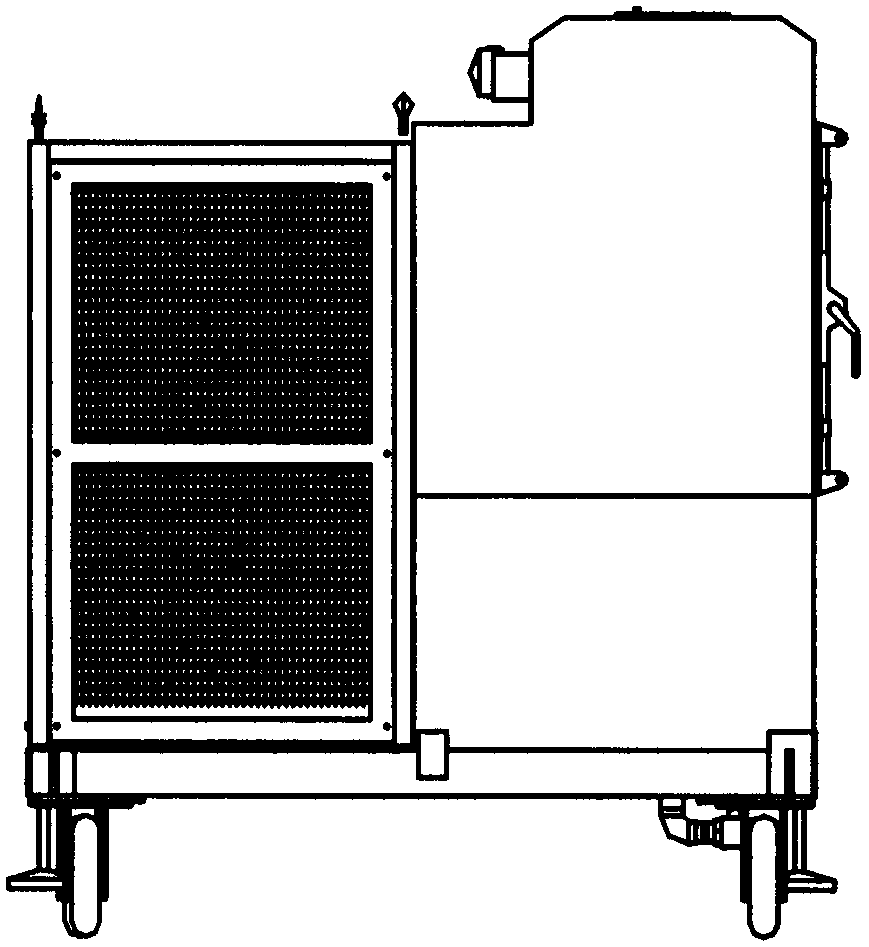

[0021] like Figure 1 to Figure 5 As shown, the present invention separates a vacuum solid-liquid separation and recovery device, including: connecting pipeline 5, deceleration chamber 2, solid waste recovery system 3, waste liquid collection system 1, waste liquid gas treatment system 4, power system 7, Safety protection device 6, industrial PLC integrated control 8, a connecting pipeline 1 is provided on the deceleration chamber, a solid waste recovery system 3 is provided under the deceleration chamber, and a waste liquid collection system 1 is provided under the solid waste recovery system, which is connected with the deceleration chamber. The warehouse is conne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap