Flue current equalizer device and design method

A flow equalizer and flue technology, which is applied in the field of flue flow equalizer device and design, can solve the problems of corrosion risk, no general design method, and inability to adapt to high-humidity flue gas of desulfurization tower, so as to reduce operation and maintenance cost, shorten the time consumed by simulation, and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

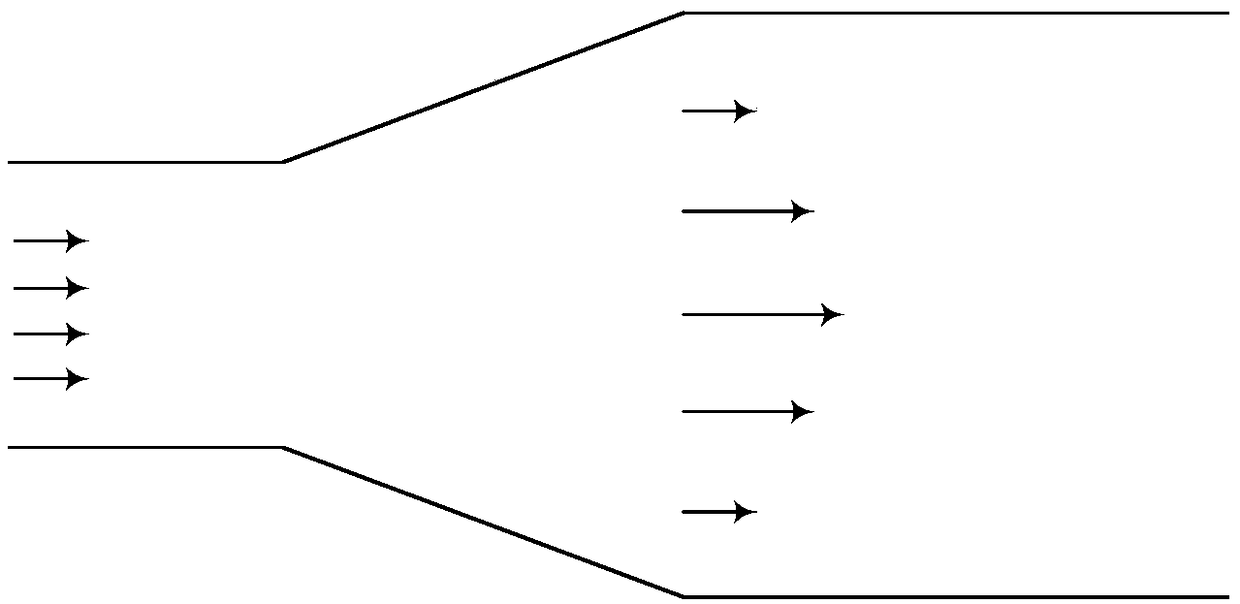

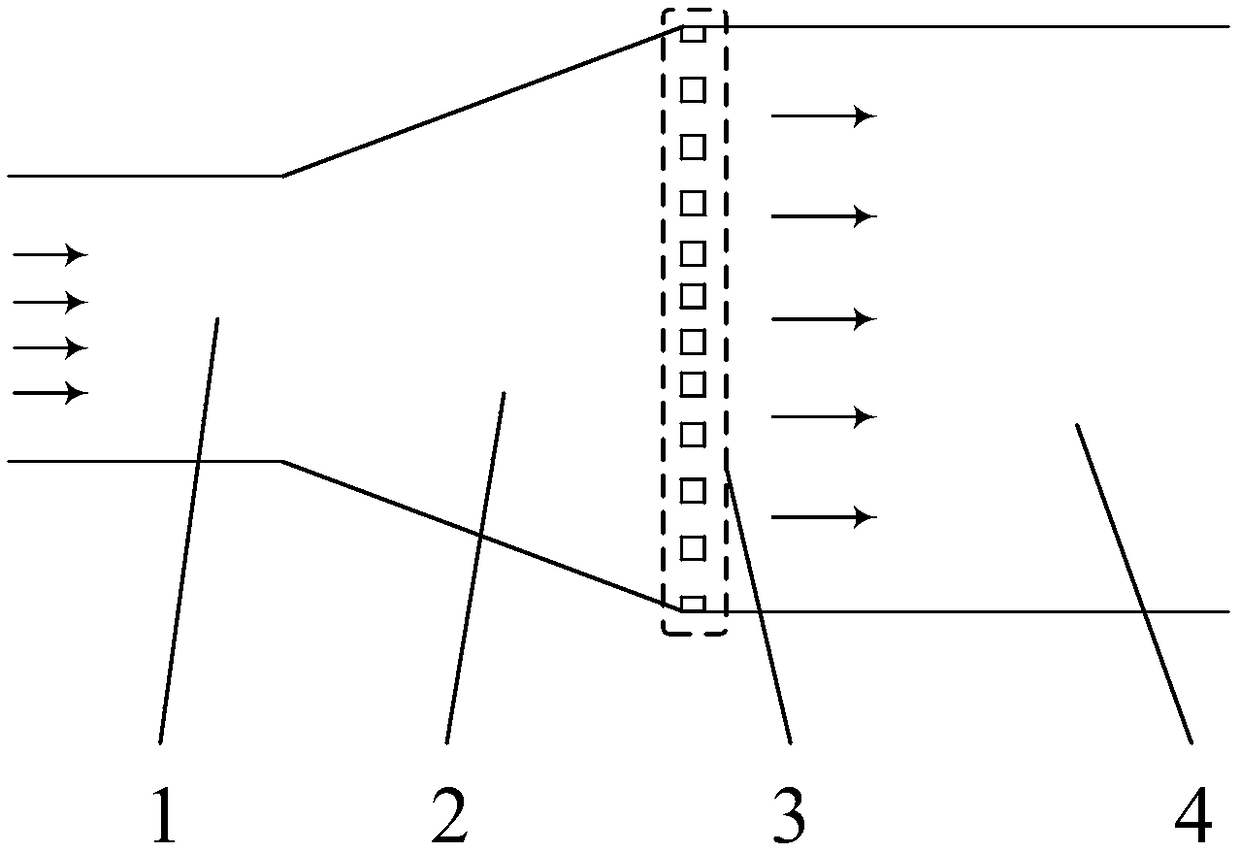

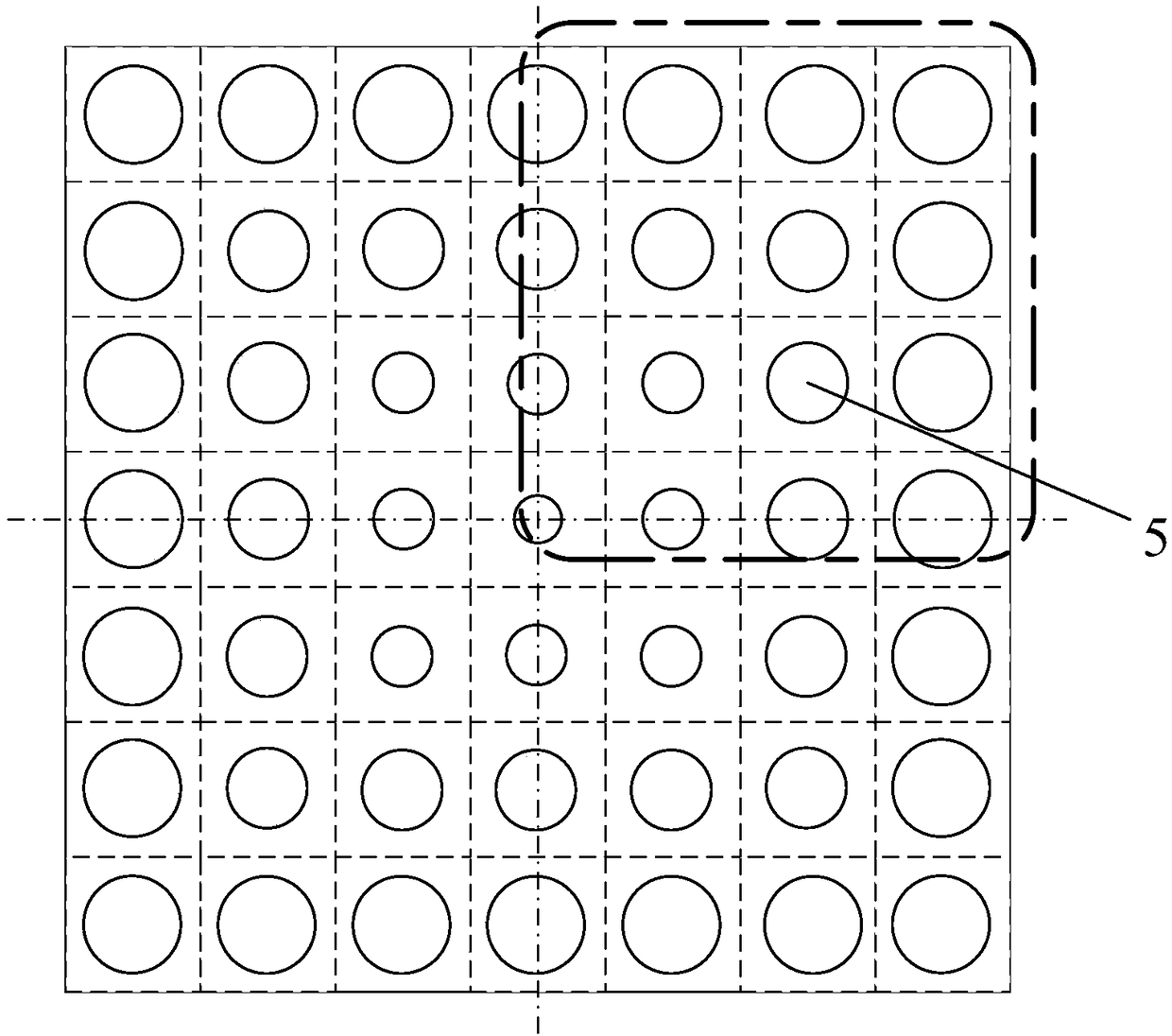

[0038] Embodiment 1, flue flow equalizer device, such as Figure 1-5 As shown, including flow equalizer 3 arranged in variable cross-section flue,

[0039] The variable-section flue includes a variable-section flue inlet section 1, a variable-section flue amplification section 2, and a variable-section flue outlet section 4 connected in sequence, and the diameter of the variable-section flue inlet section 1 is smaller than that of the variable-section flue outlet section 4. diameter.

[0040] When the variable cross-section flue is not equipped with a flow equalizer 3, the flue gas velocity distribution in the variable cross-section flue inlet section 1 is uniform. The flue gas velocity distribution in the outlet section 4 is uneven, the flue gas velocity is fast in the center of the flue, and the flue velocity near the avoiding position of the flue is slow.

[0041] In the present invention, a flue gas passing through the flow equalizer 3 is placed at the junction of the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com