Flue flow equalizer device and design method

A design method and flow equalizer technology, applied to chemical instruments and methods, separation methods, combustion methods, etc., can solve the problems of corrosion risk, inability to adapt to high-humidity flue gas of desulfurization tower, and no general design method, and achieve The effect of reducing operation and maintenance costs, shortening the time consumed by simulation, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

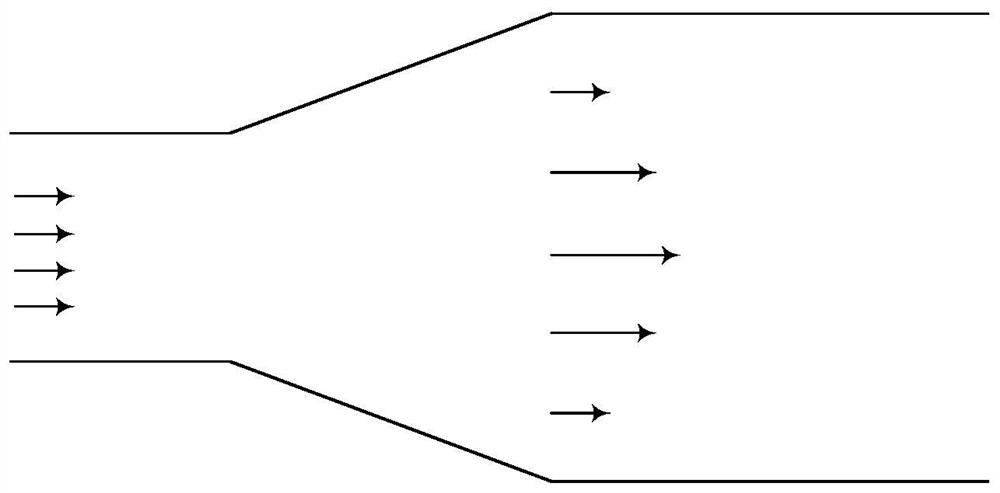

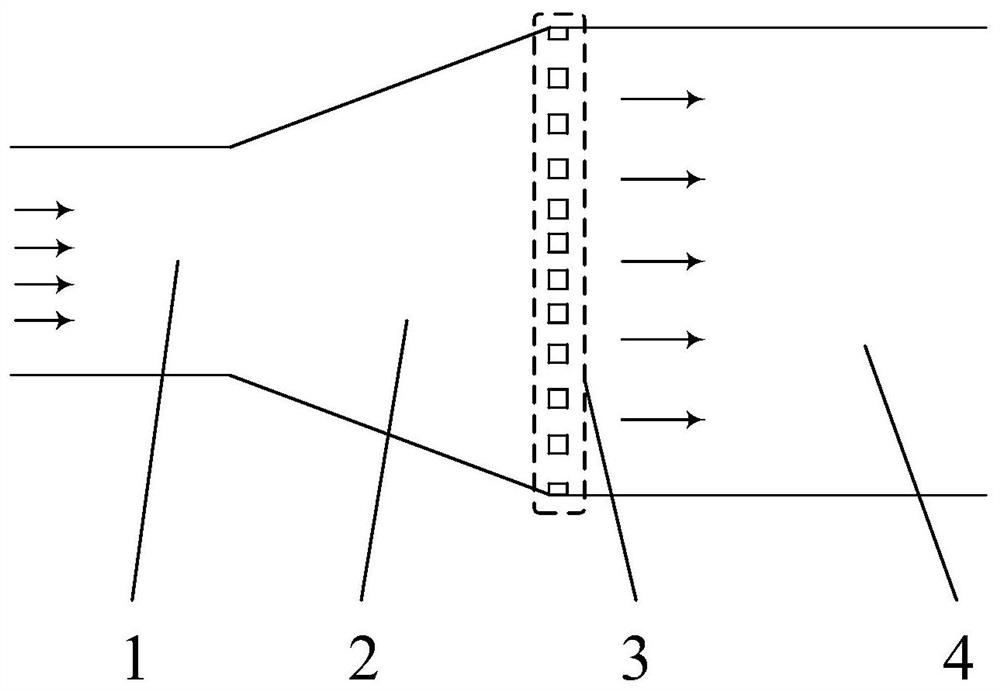

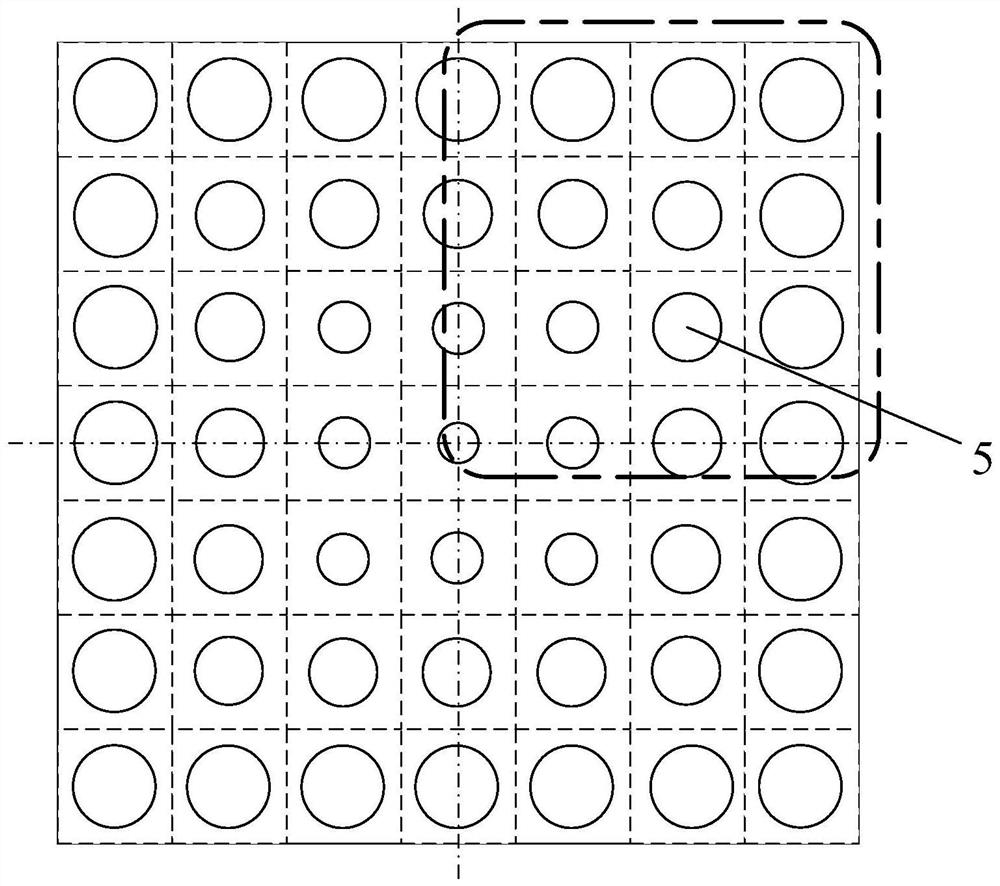

[0038] Embodiment 1, flue flow equalizer device, such as Figure 1-5 As shown, including flow equalizer 3 arranged in variable cross-section flue,

[0039] The variable cross section flue includes the variable cross section flue inlet section 1, the variable section flue enlargement section 2 and the variable section flue outlet section 4 connected in sequence, and the diameter of the variable section flue inlet section 1 is smaller than that of the variable section flue outlet section 4. diameter.

[0040] When the variable cross-section flue is not equipped with a flow equalizer 3, the flue gas velocity distribution in the variable cross-section flue inlet section 1 is uniform. The flue gas velocity distribution in the outlet section 4 is uneven, the flue gas velocity is fast in the center of the flue, and the flue velocity near the avoiding position of the flue is slow.

[0041] In the present invention, a flue gas passing through the flow equalizer 3 is placed at the jun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com